Top 10 Hydraulic Controls You Need to Know for Optimal Performance

In the field of engineering and manufacturing, the significance of hydraulic controls cannot be overstated. These systems play a vital role in the operation of construction, agricultural, and industrial machinery, where precise control is essential for optimal performance. According to a recent report by the International Society for Trenchless Technology (ISTT), hydraulic systems account for approximately 70% of heavy machinery operations. As such, understanding the fundamental aspects of these hydraulic controls is crucial for engineers, operators, and maintenance teams to enhance operational efficiency and safety.

The continuous advancements in hydraulic technology have led to sophisticated controls that improve response times and increase reliability. A study published by the Society of Automotive Engineers highlights that modern hydraulic controls are designed to reduce energy consumption by up to 30%, which not only lowers operational costs but also minimizes environmental impact. Furthermore, effective management of hydraulic systems has been shown to decrease downtime by over 25%, underscoring the importance of staying informed about the latest hydraulic control innovations. In this context, the following outline will delve into the top 10 hydraulic controls that professionals should be well-acquainted with to ensure maximal efficiency and performance in their respective fields.

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

Hydraulic controls are essential for optimizing system performance in various industrial applications. Understanding the top hydraulic controls can significantly enhance operational efficiency and reduce maintenance costs. According to a recent report by the International Fluid Power Society, nearly 25% of unexpected downtime in hydraulic systems can be attributed to improper control settings and lack of knowledge among operators. This underscores the importance of familiarizing oneself with these critical components.

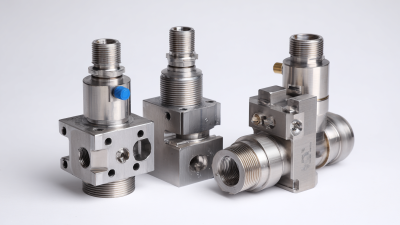

One key area to focus on is the precision of pressure control valves. These devices regulate the hydraulic pressure within a system, ensuring that machinery operates within the optimal range. Maintaining the correct pressure not only enhances performance but also prolongs equipment life. To optimize performance, it’s advisable to regularly calibrate these valves and monitor system pressures with accuracy.

Another crucial hydraulic control element is flow control valves, which manage the flow rate of hydraulic fluid, thereby influencing the speed and force of machinery. A study by the Hydraulic Institute has shown that improper flow rates can lead to energy wastage of up to 30%. Therefore, it's beneficial to invest in advanced flow measurement tools, enabling operators to tune and adjust flow rates precisely.

**Tips:** Regularly inspect and maintain hydraulic controls to keep systems running smoothly. Implement training programs for operators to better understand hydraulic principles and controls, minimizing the risk of operational issues.

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

This chart illustrates the performance efficiency of the top 10 hydraulic controls based on their flow rate capacity (L/min) and pressure system (bar). These parameters are crucial for determining the optimal performance of hydraulic systems.

Understanding the Basics of Hydraulic Control Systems and Their Importance

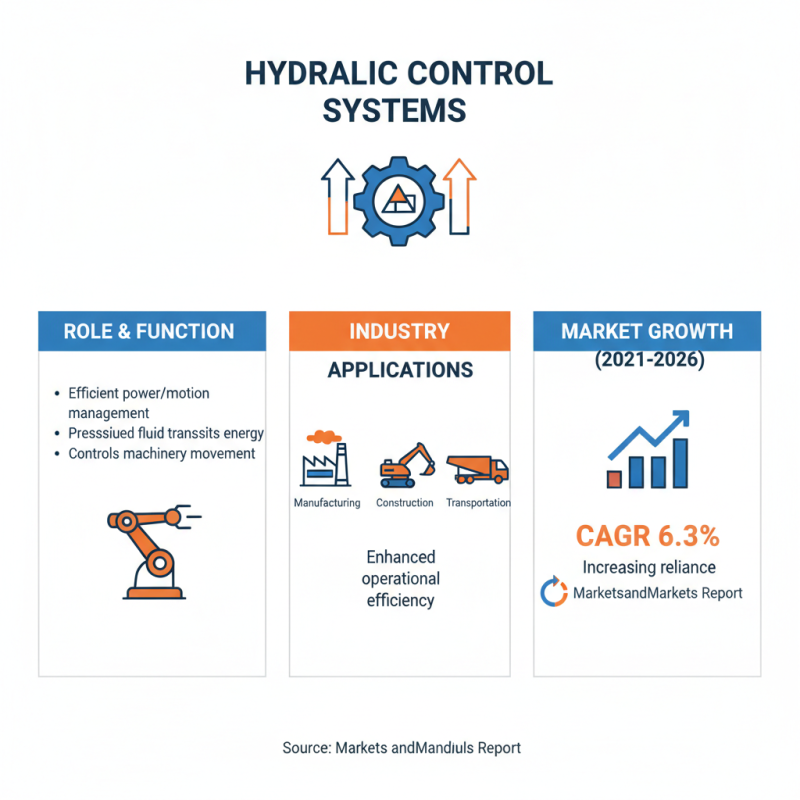

Hydraulic control systems play a pivotal role in various industries, offering efficient solutions for managing power and motion. These systems utilize pressurized fluids to transmit energy and control machinery movement, which significantly enhances operational efficiency. According to a report by MarketsandMarkets, the hydraulic systems market is anticipated to grow at a CAGR of 6.3% from 2021 to 2026, highlighting the increasing reliance on hydraulic technologies in manufacturing, construction, and transportation.

Understanding the fundamentals of hydraulic control systems is essential for optimizing performance. Key components such as pumps, valves, and actuators work together to regulate fluid flow and pressure, ensuring that equipment operates smoothly and effectively. A study by the International Journal of Fluid Power revealed that implementing advanced hydraulic control methods can improve energy efficiency by up to 30%, demonstrating their importance in reducing operational costs and optimizing resource use. By comprehensively grasping these systems, industry professionals can make informed decisions, leading to enhanced safety, productivity, and sustainability in their operations.

Key Components of Hydraulic Controls: Valves, Pumps, and Actuators Explained

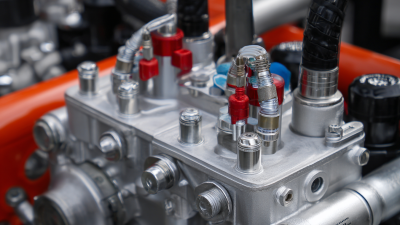

Hydraulic controls play a crucial role in the efficiency and reliability of fluid power systems, and understanding the key components—valves, pumps, and actuators—is essential for optimal performance. According to industry reports, such as those from the International Fluid Power Society, hydraulic systems typically achieve efficiencies between 70-90%, largely dependent on the quality of these components. Valves control the flow and direction of hydraulic fluid, influencing the overall responsiveness of the system. They are available in various types, including solenoid-operated, pressure-controlled, and manual valves, each serving distinct operational needs.

Pumps, on the other hand, are the heart of hydraulic systems, converting mechanical energy into hydraulic energy. They must be selected based on the system's specific requirements, including flow rate and pressure. A study by the National Fluid Power Association indicates that improper pump selection can reduce system performance by up to 25%. Meanwhile, actuators are responsible for converting hydraulic energy back into mechanical work, facilitating the movement of machinery parts, and ensuring precision in operations.

Tips: When designing a hydraulic system, prioritize the efficiency ratings of your components. Regular maintenance of valves can prevent leaks and ensure system integrity. Additionally, consider the environmental factors that may affect pump performance, such as temperature and fluid viscosity, to avoid operational inefficiencies. Remember, the synergy between valves, pumps, and actuators ultimately dictates the effectiveness of hydraulic controls in any application.

Performance Metrics: Measuring Efficiency and Response Time in Hydraulic Systems

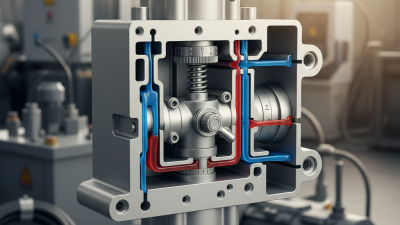

In hydraulic systems, performance metrics play a crucial role in ensuring optimal operation. Measuring efficiency involves evaluating how effectively a hydraulic system converts energy into mechanical work. This can be assessed through parameters such as flow rate, pressure levels, and temperature. By monitoring these factors, operators can identify potential inefficiencies that may arise from leakage, component wear, or improper fluid selection. Regular analysis of these metrics allows for proactive maintenance interventions, thereby enhancing the overall longevity and reliability of the system.

Response time is another critical performance metric that directly impacts the effectiveness of hydraulic controls. This is defined as the time taken for the system to respond to a command, such as adjusting the position of a hydraulic cylinder or changing the speed of a motor. Factors influencing response time include valve selections, fluid viscosity, and system design. Optimizing these elements not only improves the speed of operation but also enhances precision in applications requiring fast and accurate movement. By systematically measuring and refining response times, operators can ensure that hydraulic systems maintain peak performance under varying operational conditions.

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

| Hydraulic Control Type | Efficiency (%) | Response Time (ms) | Common Applications |

|---|---|---|---|

| Proportional Valve | 85 | 25 | Mobile Machinery |

| Pressure Relief Valve | 90 | 20 | Industrial Equipment |

| Directional Control Valve | 80 | 30 | Hydraulic Press |

| Flow Control Valve | 75 | 40 | Automation Systems |

| Hydraulic Cylinders | 87 | 35 | Construction Equipment |

| Hydraulic Motors | 82 | 45 | Agricultural Machinery |

| Accumulator | 88 | 50 | Energy Storage |

| Hydraulic Filters | 95 | 10 | Fluid Purification |

| Hydraulic Pumps | 78 | 60 | Power Generation |

| Hydraulic Hoses | 85 | 70 | Fluid Transmission |

Common Issues in Hydraulic Controls and Best Practices for Maintenance

Hydraulic controls are essential components in various industrial applications, and understanding common issues is crucial for maintaining optimal performance. One common problem arises from fluid contamination, which can lead to reduced efficiency and increased wear on components. To combat this, implementing proper filtration systems and regularly changing hydraulic fluids can help maintain cleanliness in the system. Additionally, monitoring fluid levels and ensuring appropriate viscosity are vital to prevent cavitation and other detrimental effects, ensuring that the system operates smoothly.

Another prevalent issue in hydraulic controls is the development of leaks. These can occur due to worn seals, damaged hoses, or improper connections. Regular inspections of the hydraulic system can help identify potential leak sources before they become significant problems. Utilizing proper maintenance techniques, such as torqueing fittings and conducting pressure tests, can mitigate the risk of leaks. Furthermore, periodic training for personnel on the importance of hydraulic maintenance can foster a culture of vigilance, helping to maintain peak performance and avoid unexpected downtime.

Conclusion

Hydraulic controls play a crucial role in enhancing the performance and efficiency of industrial systems. Understanding the basics of hydraulic control systems, including their key components like valves, pumps, and actuators, is essential for optimizing operations. By measuring performance metrics such as efficiency and response time, operators can ensure that their hydraulic systems are functioning at peak performance.

Moreover, being aware of common issues in hydraulic controls allows for timely maintenance and the application of best practices to prevent system failures. As technology evolves, innovative solutions are emerging to further improve the operational performance of hydraulic systems, paving the way for greater productivity and reliability in various applications.

Related Posts

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

What Are the Key Components of Hydraulics Products and Their Applications

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

What are the Benefits of Using Pressure Valves in Industrial Applications

skip to Main Content

skip to Main Content