Top 10 Fluid Control Solutions for Optimal Efficiency?

In today's fast-paced industrial landscape, fluid control solutions are crucial for achieving optimal efficiency. According to a report by MarketsandMarkets, the global fluid control market is projected to reach $32.1 billion by 2026, growing at a CAGR of 5.9%. This highlights the rising demand for advanced fluid control technologies across various sectors, including oil and gas, chemicals, and water treatment.

Expert Jamie Reynolds, a leader in fluid dynamics, emphasizes, “Effective fluid control can significantly improve operational efficiency.” This underscores the importance of selecting the right solutions. However, organizations still face challenges in integrating these technologies. Many companies overlook the need for regular maintenance and training, leading to suboptimal performance.

Fluid control is not merely about regulating flow; it involves a comprehensive understanding of processes. Implementing the right solutions can reduce waste, enhance safety, and optimize resource usage. Yet, with evolving technologies, the learning curve can be steep. Companies must reflect on their approaches to ensure they do not fall behind in this competitive industry.

Key Considerations for Choosing Fluid Control Solutions

Choosing the right fluid control solution is crucial for efficiency. There are several key factors to consider. Start with the fluid type. Is it corrosive, viscous, or high-pressure? Each fluid requires a specific material. Compatibility can prevent costly failures.

Next, think about application needs. Is the system for industrial use or a laboratory? Pressure and temperature ratings are vital. These parameters directly affect performance. You'll need to assess flow rates as well. Too low or too high can lead to inefficiencies. Understand your operational conditions fully.

Maintenance is often overlooked. Regular checks on components can make a difference. A simple clog can halt production. Look for solutions that offer easy access for repairs. It’s an area that demands reflection. Prioritize solutions that suit your long-term goals. Embrace options that provide flexibility.

Types of Fluid Control Technologies and Their Applications

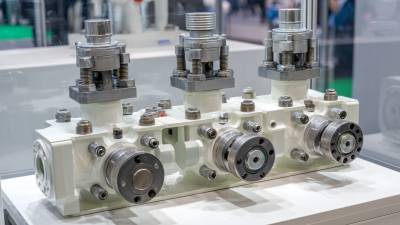

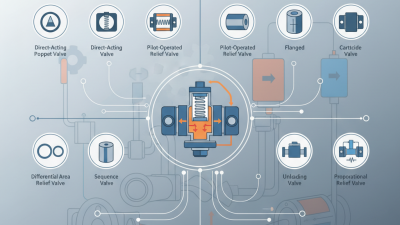

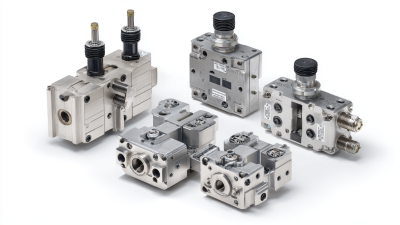

Fluid control technologies have various applications. From industrial processes to HVAC systems, efficiency is key. These technologies help manage liquids and gases effectively. Common types include valves, pumps, and flow meters. Each plays a unique role in fluid management.

Tips: Always ensure compatibility between your system and the fluid control technology.

Mismatches can lead to leaks or failures. Regular maintenance is crucial. Even a small oversight can cause significant disruptions.

Consider the environment where the technology will be used. High temperatures or corrosive substances can impact performance. Selecting the right materials and designs matters. Sometimes, achieving optimal efficiency takes trial and error. It’s a learning process. Adaptation is crucial in fluid control.

Factors Influencing Fluid Control Efficiency

Fluid control efficiency is influenced by various factors. Understanding these elements can improve operational performance significantly. One major factor is the design of the fluid system. A well-engineered system reduces leaks and maintains consistent flow rates. However, many designs often overlook maintenance access, leading to inefficiencies.

Another critical aspect is the choice of materials. Using the right materials can enhance durability and reduce corrosion. For instance, certain plastics may offer resistance to specific chemicals but could fail under high pressure. A miscalculation here can lead to unforeseen costs and downtime.

Finally, operator training is essential for achieving optimal fluid control. Well-trained personnel can identify inefficiencies quickly but inadequate training can create problems. It’s important to empower employees with the knowledge they need. Addressing these factors leads to a more effective fluid control solution, but adjustments are often required to meet unique system needs. Fluid dynamics is complex; small changes can have significant effects.

Implementing Fluid Control Solutions in Industrial Settings

In industrial environments, fluid control is essential for efficiency. Implementing effective solutions can drastically improve processes. According to a recent industry report, proper fluid management can increase efficiency by up to 30%. However, many facilities still overlook this critical area.

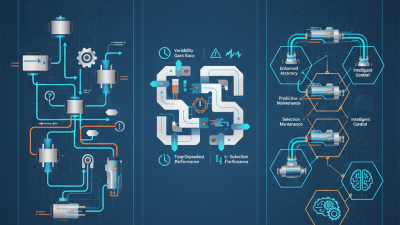

One common issue is the lack of real-time monitoring. Without it, equipment malfunctions can go unnoticed, leading to costly downtime. Incorporating sensors and automated valves can provide instant feedback. This can alert operators to deviations before they escalate.

**Tip:** Regularly review fluid performance data. Setting benchmarks helps identify areas needing improvement.

Another challenge is the complexity of fluid systems. Many operators are not fully trained on system dynamics. Misunderstandings can lead to inefficient operation, risking safety and productivity. Simplifying training and documentation can bridge this gap.

**Tip:** Maintain an updated training program. Regular workshops can boost staff knowledge significantly.

Finding the right balance in fluid control means acknowledging imperfections. Continuous feedback loops can refine processes over time. Monitoring and adapting are keys to achieving optimal efficiency in industrial settings.

Future Trends in Fluid Control Technology and Innovation

Fluid control technology is evolving rapidly. New trends focus on increasing efficiency and sustainability. Advanced sensors now allow for real-time monitoring. This monitoring helps in making quick adjustments to fluid systems. Reducing waste is a primary goal in modern designs. Every drop counts, especially in industries like agriculture and manufacturing.

Innovation in materials plays a crucial role. Lightweight, durable materials lead to better performance. However, challenges remain. Not every material can withstand extreme conditions. This aspect requires more research and testing. Additionally, integrating smart technologies raises concerns about data security. Protecting sensitive information must not be overlooked.

As we look ahead, automation will dominate fluid control systems. Automated valves and pumps promise reliable performance. Yet, reliance on technology raises risks. Unexpected failures can lead to major setbacks. The industry must prepare for potential disruptions while embracing change. The journey toward optimal fluid control efficiency is filled with opportunities and hurdles alike.

Related Posts

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

Understanding the Benefits of Pilot Operated Check Valves in Fluid Control Systems

-

2026 Top Proportional Valves for Precision Control in Automation

-

Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

skip to Main Content

skip to Main Content