Top 2025 Control Valves: Features, Trends, and Buying Guide

In the evolving landscape of industrial automation, control valves play a pivotal role in ensuring efficient process management across various sectors. As the demand for advanced control solutions continues to rise, industry experts emphasize the significance of understanding the latest features and trends in control valves to make informed purchasing decisions. Renowned control valve specialist, Dr. Emily Harrington, states, "The future of control valves lies in their ability to integrate seamlessly with smart technologies, enabling real-time monitoring and improved performance."

As we look ahead to 2025, the control valves market is expected to undergo significant transformations driven by technological advancements and the need for sustainable practices. With innovations such as digital valve positioners, predictive maintenance, and enhanced materials, these valves are evolving to meet the dynamic requirements of modern industries. Understanding these trends is crucial for businesses aiming to optimize their operations and achieve competitive advantages.

In this article, we will explore the top features that define the control valves of the future, identify prevailing trends shaping the industry, and provide a comprehensive buying guide tailored for stakeholders aiming to invest wisely in this essential equipment. By staying abreast of these developments, professionals can ensure their systems are both efficient and compliant in an increasingly complex industrial environment.

Overview of Control Valves: Definition and Functionality

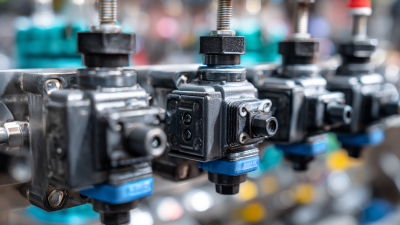

Control valves are integral components in various industrial processes, serving the critical function of regulating flow within a system. They operate by altering the size of the flow passage as directed by a controller, which receives signals based on process conditions. This functionality allows control valves to manage fluid movement effectively, ensuring that systems maintain desired pressures and flow rates. By adjusting the opening and closing of the valve, these devices can optimize performance and efficiency across applications in manufacturing, water treatment, and chemical processing, among others.

The design of control valves encompasses various features tailored to specific requirements, such as precision, durability, and responsiveness. These valves can be constructed from a range of materials, which enhances their performance in harsh environments. Additionally, advancements in technology have led to the development of intelligent control valves equipped with sensors and automation capabilities. These innovations enable real-time monitoring and adjustments, ultimately contributing to improved system reliability and reduced operational costs. Understanding these elements is essential for anyone looking to invest in or upgrade their control valve systems, as they provide the foundation for effective process management.

Key Features of Top Control Valves in 2025

In 2025, the landscape of control valves is evolving rapidly, driven by advancements in technology and the increasing demand for efficiency and reliability in industrial processes. One of the key features of top control valves will be enhanced automation capabilities. According to a recent industry report by Markets and Markets, the automation of control systems is expected to grow at a CAGR of 7.4% from 2020 to 2025, highlighting a significant shift towards smart valves integrated with IoT solutions. These valves will not only allow for remote operation but will also offer real-time data analytics for better decision-making and predictive maintenance.

Another prominent trend in control valves will be the focus on energy efficiency. As industries strive to reduce their carbon footprint, energy-efficient control valves featuring low-flow resistance and optimized flow characteristics will be essential. The Global Valves Market report indicates that energy-efficient solutions can lead to a reduction of operational costs by up to 30%, which is particularly compelling for sectors like oil and gas, water management, and chemicals.

Tips: When selecting control valves for 2025, consider models with advanced diagnostics and self-tuning features. These capabilities will enable more precise control and can significantly enhance system performance. Additionally, be sure to evaluate the materials used in valve construction, as advancements in composite and corrosion-resistant materials can extend the lifespan and reliability of your equipment.

Current Trends in the Control Valve Industry

The control valve industry is currently undergoing significant transformations driven by technological advancements and evolving market demands. One of the prominent trends is the integration of smart technology in control valves, enabling remote monitoring and automation. These smart valves can provide real-time data analytics, enhancing performance and reliability while reducing maintenance costs. As industries increasingly adopt the Internet of Things (IoT), control valves are becoming essential components in achieving greater operational efficiency and predictive maintenance strategies.

Sustainability is another crucial trend influencing the control valve market. With growing regulatory pressure and a societal push towards greener practices, manufacturers are focusing on producing energy-efficient valves that minimize environmental impact. This includes the development of valves designed for lower emissions and better energy consumption. Additionally, there is a rising demand for materials that offer durability while being environmentally friendly, leading to innovations in the materials used in control valve manufacturing. As businesses strive to meet sustainability goals, the control valve industry is evolving to provide solutions that align with these priorities.

Factors to Consider When Buying Control Valves

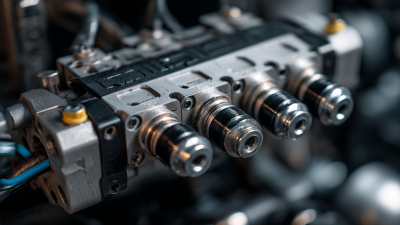

When purchasing control valves, there are several key factors to consider to ensure optimal performance and compatibility with your system. First and foremost, it's essential to understand the specific requirements of your application, including the type of fluid being controlled, operating temperature and pressure ranges, and flow characteristics.

Different control valves are designed for specific environments, so choosing a valve that can handle the physical and chemical properties of the fluid is crucial for long-term reliability.

Additionally, the actuator type is another significant aspect to evaluate. Actuators can be pneumatic, electric, or hydraulic, and each type offers distinct advantages and limitations based on the use case. It's important to assess the ease of integration with existing control systems, as well as the maintenance requirements and potential for automation. Furthermore, considering the materials of construction is vital for ensuring that the valve can withstand the working conditions and maintain performance over time. By carefully analyzing these factors, buyers can make informed decisions that enhance system efficiency and reduce operational risks.

Future Innovations and Predictions for Control Valve Technology

As the control valve industry looks towards 2025, several key innovations are poised to reshape technology and enhance performance across various applications. One prevalent trend is the integration of smart technologies, enabling control valves to communicate seamlessly with advanced monitoring systems. This interconnectedness facilitates real-time data analysis and predictive maintenance, allowing operators to anticipate failures and optimize performance without manual intervention. By harnessing the power of the Internet of Things (IoT), control valves will increasingly play a crucial role in smart manufacturing and automated processes.

Another significant prediction is the advancement in materials and design for improved durability and efficiency. With industries continuously seeking to reduce downtime and maintenance costs, manufacturers are exploring innovative materials capable of withstanding extreme conditions, such as high pressures and corrosive environments. Moreover, the design of control valves will focus on minimizing energy consumption and enhancing flow control accuracy. This shift not only supports sustainability efforts but also aligns with the growing demand for energy-efficient solutions across industrial sectors. Thus, the future of control valves is set to encompass smart functionality and robust construction, ensuring they meet the evolving needs of the market.

Related Posts

-

2025 How to Choose the Best Control Valves for Your Industrial Applications with Expert Insights

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

Top 2025 Trends in Directional Control Valves You Need to Know

-

What is the Future of Automated Valves in Modern Industries

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

-

2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

skip to Main Content

skip to Main Content