Top Benefits of Using Pump Valves for Efficient Fluid Control

In the ever-evolving field of fluid dynamics, the role of pump valves has become increasingly paramount for industries ranging from manufacturing to wastewater treatment. As experts emphasize the significance of these components, John Smith, a leading authority in fluid control technology, states, "Pump valves are not just components; they are the crucial gatekeepers that ensure the efficiency and reliability of fluid transfer systems." This assertion underscores the need for a deeper understanding of the benefits that pump valves provide in managing fluid flow with precision and control.

One of the primary advantages of using pump valves lies in their ability to enhance operational efficiency. By facilitating better flow management, these valves minimize energy consumption and reduce wear on pumping systems, resulting in lower operational costs over time. Additionally, the adaptability of pump valves across various applications makes them indispensable in optimizing fluid control processes. As industries strive for sustainability and efficiency, understanding the multifaceted benefits of pump valves becomes essential in driving innovation and promoting best practices within fluid handling operations.

Overview of Pump Valves and Their Functionality

Pump valves are essential components in fluid control systems, offering precise regulation and management of various fluids in industrial applications. Their primary function is to facilitate efficient flow management, helping to minimize energy losses and reduce operational costs. According to a report published by the International Society of Automation, nearly 30% of energy consumption in manufacturing processes can be attributed to inefficient fluid control systems. By implementing pump valves, industries can enhance flow accuracy and optimize overall system performance.

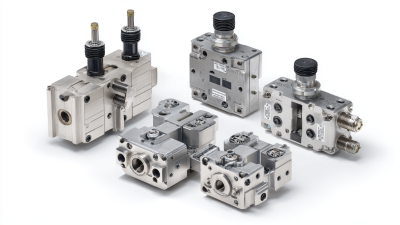

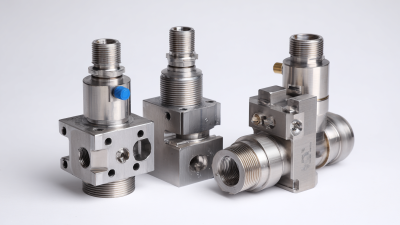

In terms of functionality, pump valves come in a variety of designs, including check valves, globe valves, and ball valves, each serving specific purposes. Check valves prevent backflow, ensuring that fluid moves in one direction, while globe valves are ideal for regulating flow in a system. A study by the American Society of Mechanical Engineers indicates that proper valve selection and maintenance can lead to a 20% increase in system efficiency. Moreover, the adoption of smart valve technology is on the rise, with market research projecting a CAGR of 9.8% in the next five years, driven by the demand for enhanced automation and control capabilities in fluid systems.

Top Benefits of Using Pump Valves for Efficient Fluid Control

Types of Pump Valves Used in Fluid Control Systems

Pump valves play a crucial role in fluid control systems, ensuring that the flow of liquids is both efficient and precise. Various types of pump valves are employed depending on the requirements of the system. Among these, ball valves are widely used due to their excellent sealing capabilities and quick operation. According to a report by the Global Industry Analysts, the market for ball valves is projected to reach USD 19.9 billion by 2024, highlighting their significance in fluid management.

Another commonly utilized type is the check valve, which allows fluid to flow in one direction while preventing backflow. This feature is essential in applications where maintaining a unidirectional flow is necessary for operational safety and efficiency. The demand for check valves is bolstered by industries such as oil and gas, which is expected to see a 4.3% annual growth in valve installations by 2025.

Additionally, globe valves provide excellent throttling capabilities and are ideal for applications requiring fine flow control. Their versatility makes them a popular choice in both industrial and commercial fluid systems.

Making informed decisions on valve selection can greatly enhance system efficiency and longevity. As industries increasingly look for ways to optimize fluid control, understanding the specific benefits and applications of each pump valve type will be vital for engineers and decision-makers. According to an industry survey, nearly 65% of fluid management professionals believe that using the right combination of valves can lead to significant energy savings, further underscoring the importance of appropriate valve selection in fluid control systems.

Key Advantages of Implementing Pump Valves in Systems

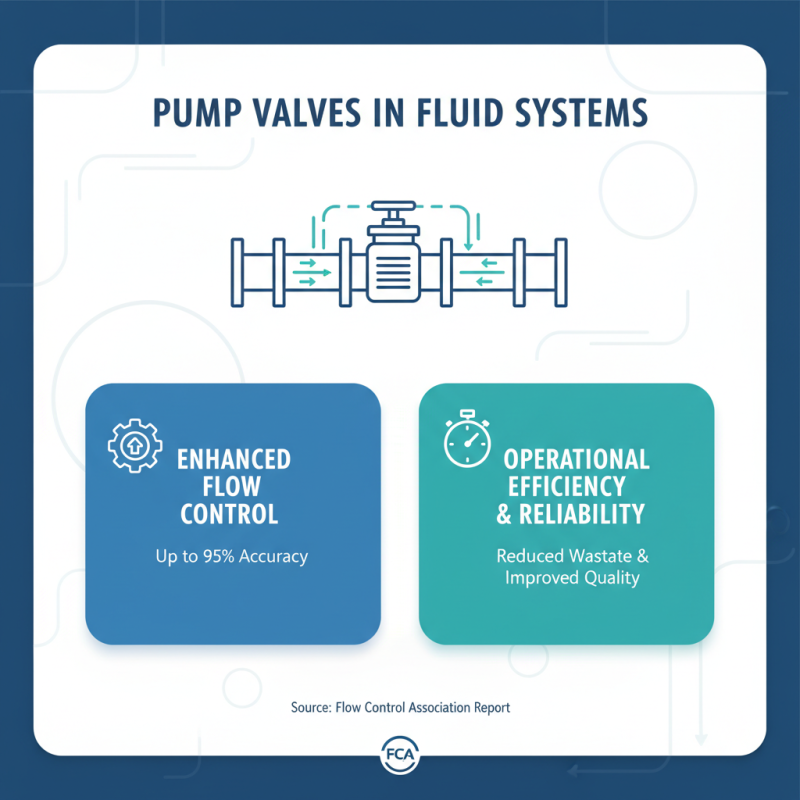

The implementation of pump valves in fluid systems offers several key advantages that contribute to operational efficiency and reliability. One significant benefit is the enhanced control over fluid flow. According to a recent report from the Flow Control Association, systems that utilize pump valves can achieve flow regulation accuracy of up to 95%, significantly reducing wastage and improving overall performance. This precision is crucial in industries where maintaining specific flow rates directly influences product quality and operational efficiency.

Another advantage lies in the versatility of pump valves. They can operate across a wide range of pressure and temperature conditions, making them suitable for diverse applications, from water treatment to chemical processing. Research by the International Journal of Fluid Mechanics highlights that incorporating pump valves can lower energy consumption by up to 20%, as they allow for better modulation of the pump's operation based on real-time system demands. This adaptability not only leads to substantial cost savings but also promotes sustainability by minimizing unnecessary energy use and operational costs.

Furthermore, the reliability of pump valves boosts system longevity. The American Society of Mechanical Engineers has reported that systems equipped with high-quality pump valves experience 30% fewer maintenance events, which translates to reduced downtime and increased productivity. By integrating pump valves into fluid control systems, industries can enhance their operational efficiency while ensuring superior performance and reduced costs over time.

Factors to Consider When Choosing Pump Valves

When choosing pump valves for efficient fluid control, several key factors must be considered to ensure optimal performance and longevity. First and foremost, understanding the operating environment is critical. This includes assessing the temperature, pressure, and type of fluid being handled. For instance, corrosive or abrasive fluids may require specially coated or reinforced valves to prevent early wear and failure. Additionally, the flow rate requirements should be evaluated to match the pump valve's specifications effectively, ensuring that it can handle the desired flow without causing disruptions in the system.

Another important factor is the valve type, which can significantly influence the fluid control. Options such as gate, globe, ball, and check valves each offer unique advantages that cater to different applications. For example, ball valves are ideal for on-off controlled flow while globe valves provide better throttling capabilities. The material of the valve is equally important, as materials like stainless steel, brass, or plastics offer varying degrees of durability and resistance to environmental factors. Moreover, considering maintenance needs, such as ease of repair and availability of replacement parts, can help in making a more informed decision that aligns with operational goals.

Common Applications of Pump Valves in Various Industries

Pump valves play a crucial role across various industries by enabling efficient fluid control in numerous applications. In the water treatment sector, for instance, pump valves are essential for regulating the flow of chemicals used in the purification process. According to a report by the Global Water Intelligence, the market for water and wastewater treatment equipment is expected to reach $850 billion by 2025, largely driven by advancements in valve technology and automation. These pump valves help maintain optimum pressure and flow rates, ensuring the efficiency of treatment plants while minimizing energy consumption.

In the oil and gas industry, pump valves are indispensable for safely transporting hydrocarbons. The International Energy Agency (IEA) has predicted a rise in global oil demand to 104 million barrels per day by 2023. The need for reliable and durable pump valves in this context cannot be overstated, as they prevent leaks and ensure safe operation under high pressures and temperatures. These valves facilitate not only the extraction but also the refinement and distribution of oil, contributing to a seamless supply chain that is vital for meeting energy demands worldwide. Additionally, the petrochemical sector relies on these valves for critical processes, including fluid transfer and isolation, which further highlights their versatility and importance in industrial applications.

Top Benefits of Using Pump Valves for Efficient Fluid Control - Common Applications of Pump Valves in Various Industries

| Benefit | Application Industry | Common Fluid Types | Efficiency Improvement |

|---|---|---|---|

| Precise Flow Control | Chemical Processing | Chemical Solutions | Up to 30% Reduction in Waste |

| Durable and Reliable | Water Treatment | Water and Wastewater | Extends Equipment Lifespan |

| Energy Efficiency | Oil and Gas | Crude Oil, Natural Gas | Reduces Energy Costs by 20% |

| Reduced Maintenance | Pharmaceutical | Sterile Solutions | Maintenance Frequency Cut by 50% |

| Safety and Compliance | Food and Beverage | Food Products, Beverages | Meets Strict Health Standards |

Related Posts

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

-

How to Choose the Right Hydraulic Check Valve for Your System

-

Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

skip to Main Content

skip to Main Content