What is Pressure Control? Understanding Techniques and Applications

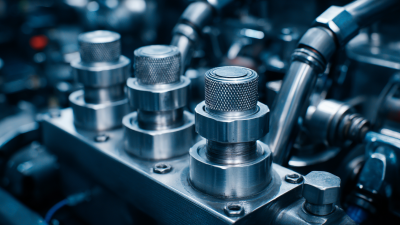

Pressure control is a fundamental aspect of numerous industrial and scientific processes, playing a pivotal role in maintaining operational efficiency and safety. In various applications, whether in manufacturing, chemical processing, or environmental management, the ability to regulate pressure levels effectively is essential. This introduction aims to shed light on the significance of pressure control, exploring the techniques and methodologies employed to achieve optimal results.

Understanding pressure control begins with recognizing its importance in controlling fluid dynamics and maintaining the integrity of systems. Techniques such as valve regulation, feedback loops, and sensor integration are common strategies used to manipulate pressure levels precisely. This article will delve into the intricacies of these methods, providing insights into their practical applications across different sectors. By grasping the fundamentals of pressure control, engineers and operators can enhance performance, ensure safety, and contribute to a more sustainable approach in their respective fields.

Ultimately, masterfully navigating the complexities of pressure control not only leads to innovation and efficiency but also ensures compliance with safety standards and regulations. As we explore this crucial topic further, we will identify best practices and emerging trends that highlight the evolving nature of pressure control techniques and their applications in the modern world.

Definition and Principles of Pressure Control

Pressure control is a critical aspect in various industries, encompassing the maintenance and regulation of pressure within systems to ensure safety and efficiency. It involves understanding the forces exerted by gases or liquids in confined spaces, and this understanding is rooted in fundamental physical principles. Pressure, defined as force per unit area, can be manipulated by adjusting the volume, temperature, or amount of gas or liquid present in a system, as described by the ideal gas law.

In practical terms, pressure control techniques can vary widely from simple mechanical means, such as pressure relief valves, to sophisticated automated systems that use sensors and control algorithms. These techniques are essential in applications ranging from manufacturing processes to the aerospace industry, where precise pressure management is crucial for operational stability. Effective pressure control not only enhances the performance and reliability of equipment but also plays a significant role in safety measures to prevent hazardous situations associated with pressure build-up. Understanding these principles and their applications is key for engineers and technicians working in fields that heavily rely on pressure systems.

Pressure Control Techniques and Applications

This bar chart illustrates the relative popularity of various pressure control techniques, highlighting the prevalence of pneumatic control systems in diverse applications.

Key Techniques in Pressure Control Systems

Pressure control systems are crucial in a variety of medical devices, especially in critical applications like ventilators. The COVID-19 pandemic highlighted the urgent need for effective and reliable pressure control mechanisms to ensure that ventilators can deliver adequate respiratory support to patients. Techniques such as closed-loop control algorithms allow for real-time adjustments in pressure settings based on patient needs, optimizing ventilation while minimizing the risk of lung injury due to overpressure.

Rapidly deployable solutions, like low-cost ventilators, illustrate the significance of these pressure control techniques in emergency situations.

In addition to ventilators, pressure control is essential in other areas, such as continuous glucose monitoring systems. These devices often utilize sophisticated algorithms to maintain optimal pressure levels for accurate blood sample analysis. The integration of AI in these systems not only enhances the precision of glucose predictions but also facilitates effective calibrations, improving overall patient management in diabetes care. As technology advances, the role of pressure control techniques in medical devices continues to become increasingly sophisticated and vital.

Applications of Pressure Control in Various Industries

Pressure control is a critical aspect in a variety of industries, enhancing safety, efficiency, and product quality. In the oil and gas sector, for example, maintaining optimal pressure levels is essential for preventing blowouts and optimizing extraction processes. According to a report by the International Energy Agency (IEA), effective pressure management can improve recovery rates by up to 10% , significantly impacting overall production.

In the pharmaceutical industry, pressure control is vital during the manufacturing processes to ensure product integrity and compliance with stringent regulations. The FDA mandates specific pressure conditions for sterilization processes, which if not met, could compromise the efficacy of pharmaceutical products. Studies indicate that improper pressure control during production could lead to up to 20% batch failures, highlighting the importance of precise monitoring systems.

Tip: To implement pressure control effectively, companies can invest in automated pressure monitoring systems that provide real-time data analytics. This allows for timely adjustments and helps mitigate risks associated with pressure fluctuations.

Moreover, the food processing industry utilizes pressure control in techniques such as High-Pressure Processing (HPP). This method not only extends shelf life but also preserves nutritional quality. A report from the Food Processing Association notes that HPP can retain over 90% of vitamins compared to traditional methods.

Tip: Regular training for staff on the latest pressure management technologies can enhance operational efficiency and maintain high safety standards.

Challenges and Solutions in Implementing Pressure Control

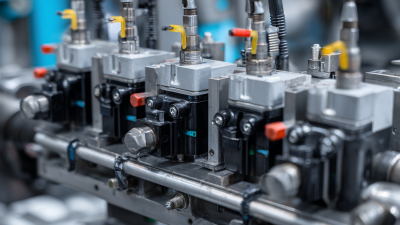

Implementing effective pressure control can pose several challenges across various industries. One significant issue is the variability in system dynamics and external conditions that affect pressure levels. For instance, in hydraulic systems, fluctuations caused by changes in load or temperature can lead to undesired pressure spikes or drops. Addressing these variations requires sophisticated sensors and control algorithms that can adapt in real-time, which can be both costly and complex to maintain.

Another challenge lies in the integration of pressure control systems with existing infrastructure. Many facilities have legacy equipment that may not easily support modern control technologies, leading to interoperability issues. Solutions to this can involve retrofitting existing systems with compatible components or investing in hybrid systems that enhance flexibility while ensuring reliability. Training personnel to operate and troubleshoot these advanced systems is equally crucial, as the human factor plays a key role in achieving successful pressure management and minimizing risks associated with pressure fluctuations.

What is Pressure Control? Understanding Techniques and Applications - Challenges and Solutions in Implementing Pressure Control

| Techniques | Applications | Challenges | Solutions |

|---|---|---|---|

| PID Control | Chemical Process Industries | Drift in measurement | Regular calibration of sensors |

| Model Predictive Control (MPC) | Oil and Gas Industry | Computational complexity | Simplifying models and promoting parallel processing |

| Fuzzy Logic Control | Water Treatment Facilities | Uncertainty in data | Robust data handling techniques |

| Adaptive Control | Pharmaceutical Manufacturing | Non-linear process behavior | Utilizing machine learning for process adaptation |

Future Trends in Pressure Control Technology

Future trends in pressure control technology are evolving rapidly, shaped by advancements in automation and smart sensor integration. The global market for pressure control tools, which includes drilling tools, pressure and flow control tools, handling tools, and impurity control tools, is expected to witness significant growth. Reports indicate that the market size for these tools reached approximately $10 billion in 2022, with projections suggesting an annual growth rate exceeding 7% through 2030. This growth is driven by increasing demand across various applications including well drilling, well completion, intervention, and production activities.

Moreover, the integration of artificial intelligence and machine learning in pressure control systems is poised to enhance operational efficiency and safety. As companies strive for greater automation, the reliance on sophisticated analytics and predictive maintenance will become paramount. According to industry analysis, the adoption of smart pressure control systems could lead to a 25% reduction in operational costs for companies within the oil and gas sector.

As pressure control technology continues to advance, it is vital for industry stakeholders to stay abreast of these trends in order to leverage new opportunities and remain competitive in the market landscape.

Related Posts

-

What is the Future of Automated Valves in Modern Industries

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

-

Revolutionizing Flow Control: How Automated Valves are Shaping the Future of Industrial Automation

-

2025 How to Choose the Best Control Valves for Your Industrial Applications with Expert Insights

-

How to Choose the Right Electric Valves for Your Industrial Applications

skip to Main Content

skip to Main Content