Understanding the Power of Pneumatic and Hydraulic Systems in Modern Industry with Over 300 Billion USD Revenue

In today's industrial landscape, pneumatic and hydraulic systems play a pivotal role, contributing to a staggering revenue of over 300 billion USD globally. These systems, characterized by their ability to transmit power through compressed air and fluid pressure, are essential in various applications ranging from manufacturing to construction. According to a recent industry report by MarketsandMarkets, the global hydraulic equipment market is expected to grow from 45.2 billion USD in 2020 to 62.9 billion USD by 2025, highlighting the increasing reliance on these systems. Similarly, the pneumatic systems market is projected to expand at a significant CAGR, driven by advancements in automation and the demand for energy-efficient solutions. Understanding the capabilities and benefits of pneumatic and hydraulic technologies is crucial for businesses aiming to enhance operational efficiency and reduce downtime in today's competitive market.

Exploring the Fundamentals of Pneumatic and Hydraulic Systems in Industrial Applications

Pneumatic and hydraulic systems play a crucial role in modern industrial applications, contributing significantly to efficiency and productivity. According to a report by the Pneumatic and Hydraulic Equipment Association, these systems combined generated over $300 billion in global revenue in 2023. This impressive figure underscores the widespread reliance on these technologies across various sectors, including manufacturing, construction, and automotive industries.

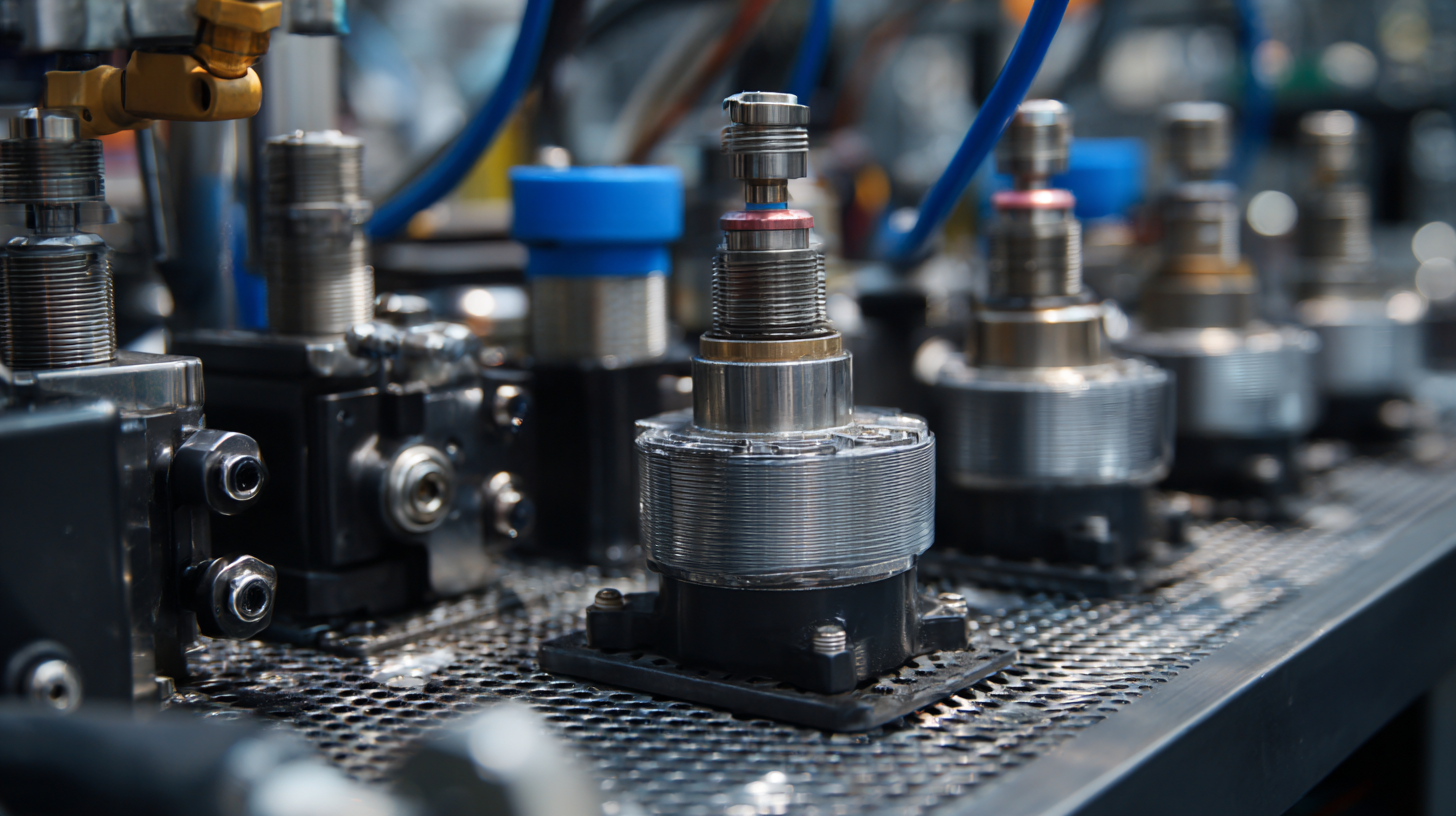

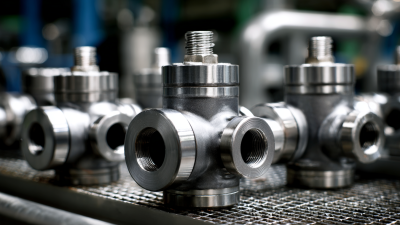

At the core of pneumatic systems is compressed air, which is utilized to power tools, actuate machinery, and automate processes. Their advantages include ease of use, safety, and cost-effectiveness. Conversely, hydraulic systems leverage incompressible fluids to transmit power, making them ideal for applications requiring high force, such as in heavy equipment and robotics. The International Fluid Power Society notes that while hydraulic systems can handle substantial loads, the ongoing maintenance and potential hazards associated with hydraulic leaks necessitate careful management.

The evolution of these systems, alongside advanced materials and technological innovations, continues to revolutionize industrial processes. The integration of smart technologies with pneumatic and hydraulic systems enhances monitoring and operational efficiency, paving the way for further growth within the industry. As companies seek to optimize their production methods, the importance of these systems becomes increasingly evident, with applications expanding into new domains, including renewable energy and automation sectors.

Understanding the Power of Pneumatic and Hydraulic Systems in Modern Industry

Identifying Key Advantages of Pneumatic and Hydraulic Technologies for Businesses

Pneumatic and hydraulic systems have become indispensable in modern industry,

generating over $300 billion in revenue globally.

These technologies offer unique advantages that drive efficiency and performance across various sectors.

One of the key benefits of pneumatic systems is their lightweight construction and rapid response time,

making them ideal for applications requiring fast and precise movements. According to a report by

MarketsandMarkets, the global pneumatic systems market is projected to reach

$40 billion by 2025, showcasing the growing reliance on these systems to enhance productivity.

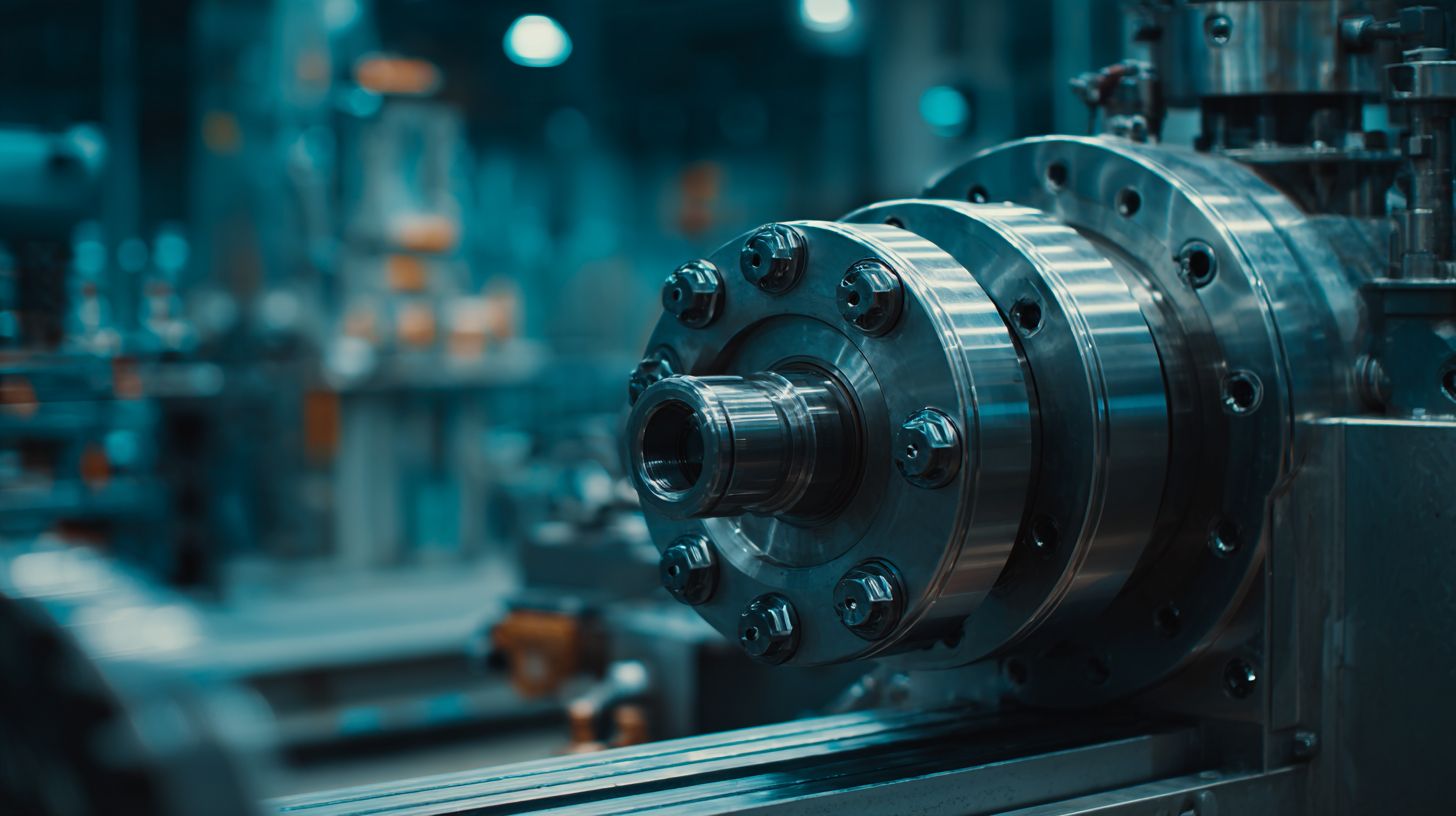

On the other hand, hydraulic systems excel in applications that demand high power and force,

such as heavy machinery and industrial equipment. Hydraulic systems can transmit power over long distances,

making them essential for construction and manufacturing industries. A study from

ResearchAndMarkets highlights that the hydraulic systems market is expected to grow at a

CAGR of over 6% during the forecast period,

indicating a strong trend towards automation and enhanced capabilities in handling heavy loads.

By leveraging both pneumatic and hydraulic technologies, businesses can optimize their operations,

reduce downtime, and achieve significant cost savings.

Evaluating the Role of Pneumatic and Hydraulic Systems in Manufacturing Efficiency

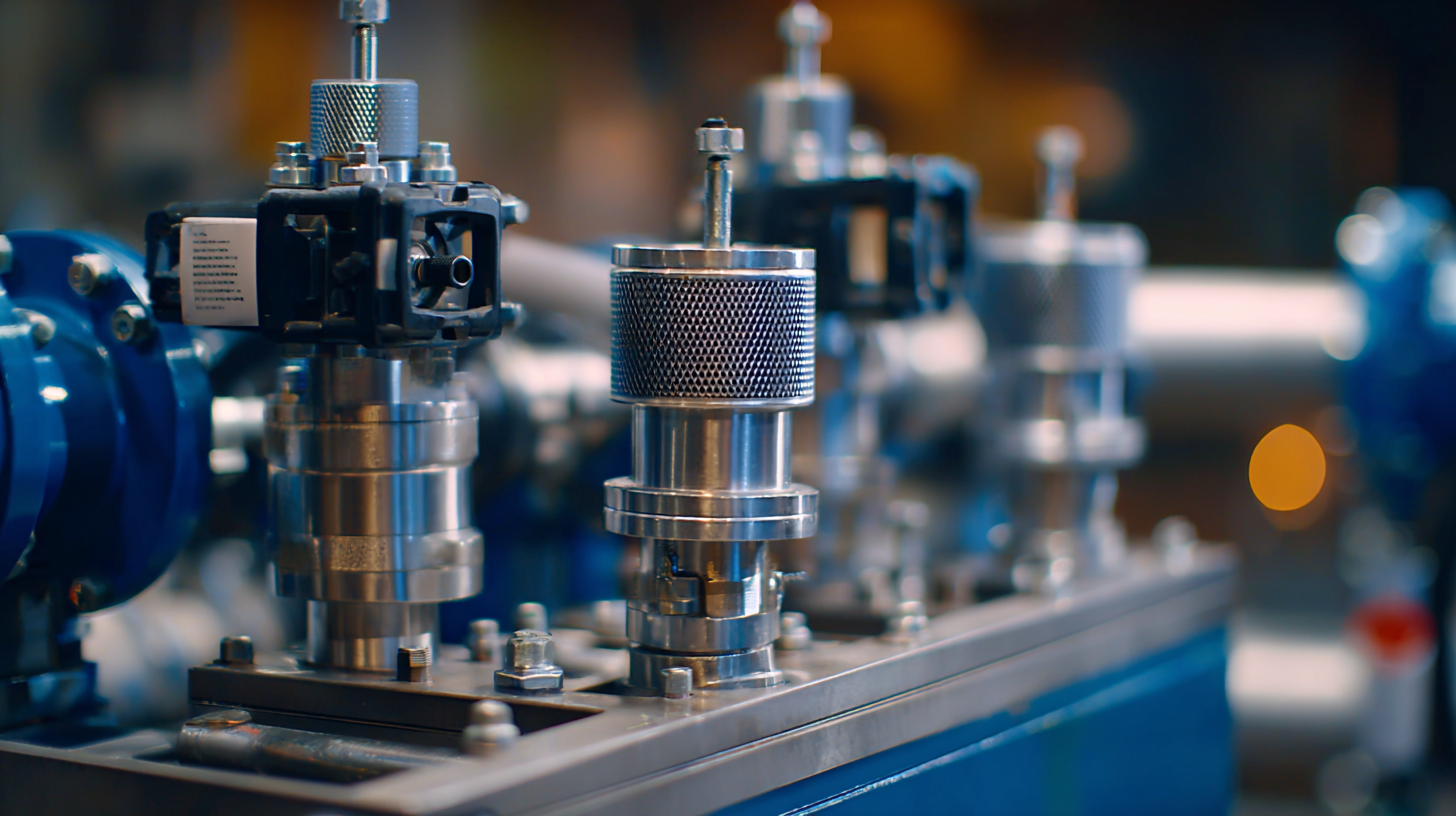

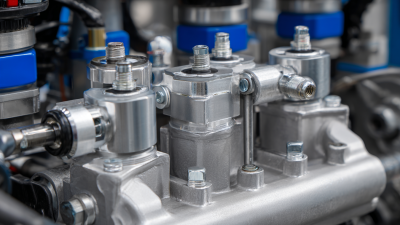

Pneumatic and hydraulic systems play a crucial role in enhancing manufacturing efficiency across various industries. As modern engineering evolves, manufacturers are increasingly focusing on key metrics that distinguish modern hydraulic system designs from conventional ones. This shift towards advanced hydraulic power units emphasizes the need for innovative approaches that improve performance, reduce energy consumption, and promote sustainability. Technologies such as electric actuators are gaining traction, providing precision and lower total cost of ownership, thus reshaping the dynamics of traditional hydraulic systems.

In addition, the integration of artificial intelligence and machine learning in fluid power systems is unlocking significant benefits in terms of predictive maintenance and overall efficiency. Manufacturers are now assessing energy consumption more rigorously, comparing motor-controlled and valve-controlled systems to identify optimal solutions. The influence of sustainability on hydraulic and pneumatic applications cannot be overlooked, as industry stakeholders prioritize reducing environmental impact while maintaining productivity. As such, the focus on sophisticated design and operational strategies continues to drive the evolution of these systems in the quest for enhanced manufacturing efficiency.

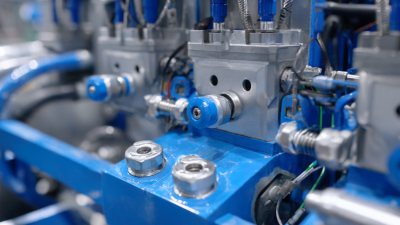

Implementing Best Practices for Maintenance and Safety in Fluid Power Systems

Pneumatic and hydraulic systems play a crucial role in modern industrial applications, with a combined revenue surpassing 300 billion USD. To maximize their effectiveness, implementing best practices for maintenance and safety is essential. According to the International Fluid Power Society (IFPS), nearly 70% of system failures can be attributed to improper maintenance and neglect. Regular inspections, proper fluid management, and timely component replacements are vital strategies that can significantly reduce operational downtime and enhance system reliability.

Moreover, safety in fluid power systems cannot be overstated. The Occupational Safety and Health Administration (OSHA) reports that incidents involving fluid power systems account for a significant percentage of workplace accidents each year. To mitigate risks, industries are encouraged to establish comprehensive safety training programs and adhere to standards set by organizations such as the American National Standards Institute (ANSI). By fostering a culture of safety awareness and following best maintenance practices, companies can not only protect their workforce but also optimize the performance of their pneumatic and hydraulic systems, ultimately leading to increased productivity and lower operational costs.

Assessing Future Trends and Innovations in Pneumatic and Hydraulic Engineering

The future of pneumatic and hydraulic systems in the industrial sector is poised for significant transformation, driven by innovations in technology and evolving market demands. According to a report from MarketsandMarkets, the global hydraulic equipment market alone is expected to reach approximately $60 billion by 2026, representing a CAGR of around 4.5%. This growth highlight reflects the increasing reliance on these systems for efficiency, precision, and automation in various industries such as manufacturing, construction, and automotive.

In terms of trends, the integration of IoT (Internet of Things) with pneumatic and hydraulic systems is anticipated to enhance operational efficiency and predictive maintenance. A study from Technavio projects that the adoption of IoT in hydraulic systems could contribute to a revenue growth of around $4 billion by 2023. Moreover, innovations in materials, such as the development of lightweight and durable composite materials, are likely to improve the performance and energy efficiency of hydraulic components, further supporting the industry’s evolution. As companies shift towards smarter, more sustainable manufacturing practices, the demand for advanced pneumatic and hydraulic solutions will remain integral to achieving operational excellence.

Related Posts

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

Innovative Flow Control Valves on Display at the 138th Canton Fair in 2025

-

Why Investing in High-Quality Check Valves Can Reduce Operational Costs by Up to 30%

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

skip to Main Content

skip to Main Content