How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

Hydraulic flow control valves are essential components in many hydraulic systems, playing a crucial role in regulating the flow of fluid to ensure optimal performance. According to a report by Markets and Markets, the global hydraulic valves market is projected to reach USD 5.9 billion by 2025, growing at a CAGR of 6.3%. This growth underscores the increasing reliance on hydraulic systems across various industries such as manufacturing, construction, and automotive. However, as the demand for efficiency and productivity intensifies, simply integrating hydraulic flow control valves is not enough. Optimizing these valves is vital for achieving maximum efficiency, minimizing energy consumption, and reducing operational costs. This blog will delve into effective strategies and practices for optimizing hydraulic flow control valves, enabling businesses to enhance their hydraulic systems' performance and sustainability.

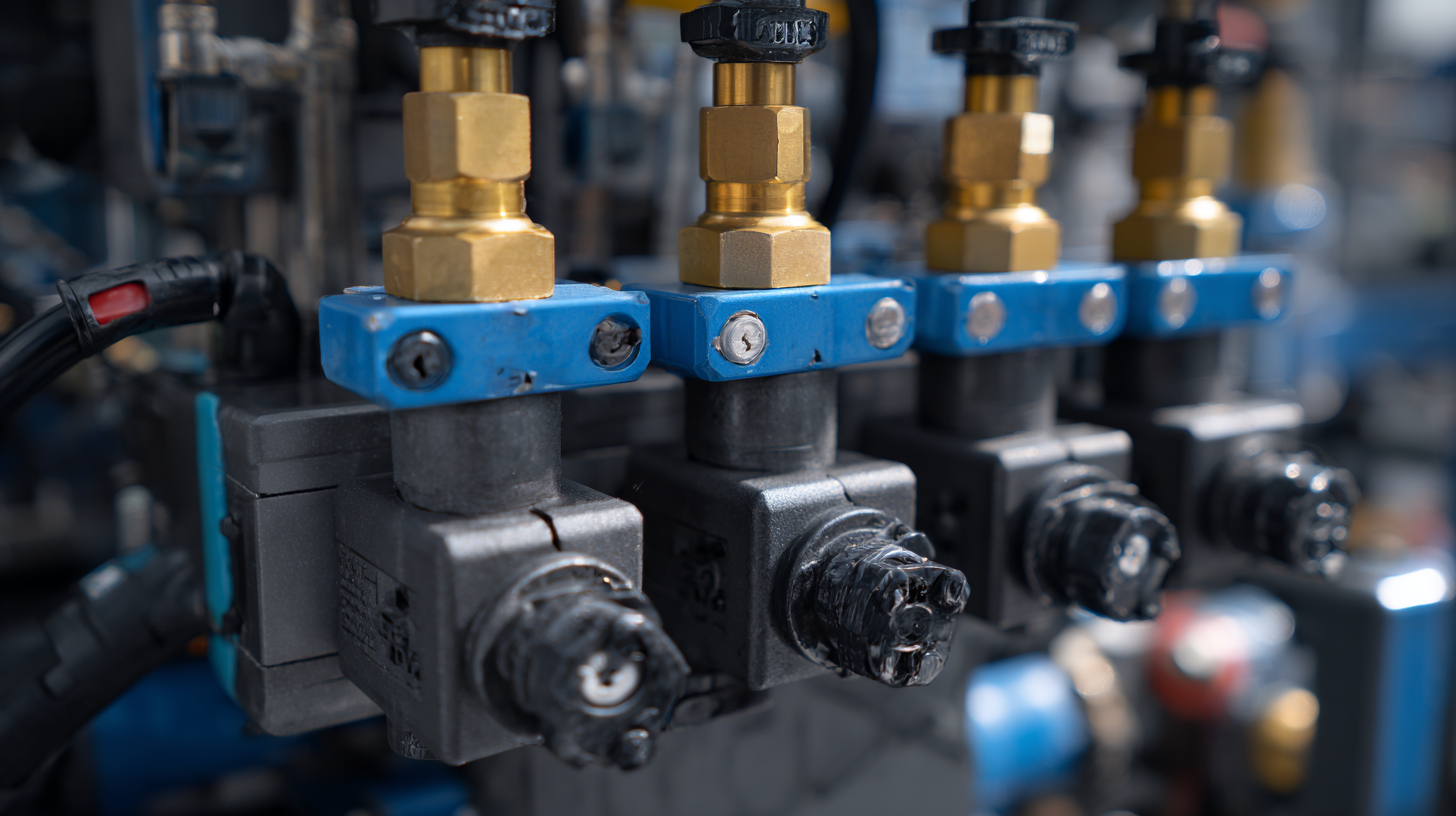

Understanding the Basics: Key Components of Hydraulic Flow Control Valves

Hydraulic flow control valves are crucial components in hydraulic systems, responsible for regulating the flow and pressure of hydraulic fluids. Understanding the key components of these valves is essential for optimizing their performance. The primary components include the valve body, actuator, and control mechanisms. Reports from industry leaders suggest that poorly optimized valves can lead to energy losses of up to 30%, emphasizing the importance of proper understanding and adjustment of these components.

To enhance the efficiency of hydraulic flow control valves, consider implementing regular maintenance schedules. Ensuring that the valve bodies are free of debris and that seals are intact can significantly improve performance. Additionally, utilizing flow meters can provide real-time data, enabling operators to make informed adjustments and detect inefficiencies promptly.

Furthermore, selecting the right actuator type—whether linear or rotary—can significantly impact the system’s responsiveness. According to a study by Fluid Power Journal, systems optimized with precise actuators can achieve up to 25% better energy efficiency. Regularly reviewing the entire hydraulic system to identify misalignments or wear can also lead to more effective flow control and overall system performance.

Identifying Common Issues That Reduce Flow Efficiency

Hydraulic flow control valves are essential components in fluid power systems, but several common issues can significantly reduce their efficiency. One prevalent problem is the presence of contaminants in the hydraulic fluid, which can lead to wear and tear on the valve's internal components. These particles create abrasive conditions, causing improper sealing and resulting in leaks that diminish the system's overall performance. Regular filtration and maintenance of the hydraulic fluid can mitigate these risks and improve flow efficiency.

Hydraulic flow control valves are essential components in fluid power systems, but several common issues can significantly reduce their efficiency. One prevalent problem is the presence of contaminants in the hydraulic fluid, which can lead to wear and tear on the valve's internal components. These particles create abrasive conditions, causing improper sealing and resulting in leaks that diminish the system's overall performance. Regular filtration and maintenance of the hydraulic fluid can mitigate these risks and improve flow efficiency.

Another issue often encountered is improper valve sizing. When a valve is not appropriately sized for the specific application, it can lead to excessive pressure drops or flow restrictions, hampering the intended hydraulic performance. To maximize efficiency, it’s crucial to accurately assess the flow requirements and select valves that match the operational parameters of the system. Additionally, issues such as cavitation, caused by high fluid velocities and low pressures, can also disrupt the flow control, making it necessary to evaluate and adjust the system design to prevent such occurrences. By addressing these common problems, operators can significantly enhance the efficiency of hydraulic flow control valves.

Top 5 Techniques for Fine-Tuning Valve Settings

Optimizing hydraulic flow control valves is crucial for enhancing system efficiency and performance. Fine-tuning valve settings not only increases operational reliability but can also lead to significant energy savings. According to a report from the Hydraulic Institute, improperly adjusted valves can result in energy losses of up to 30%, emphasizing the importance of meticulous control in hydraulic systems.

One of the top techniques for optimizing valve settings involves adjusting the flow rate to match system requirements accurately. Utilizing smart sensors and feedback mechanisms can help determine the precise flow needed for specific applications, which minimizes excess energy expenditure. Additionally, employing high-precision pressure gauges allows for better monitoring of pressure drops across valves, ensuring they operate within optimal parameters. A study by the International Fluid Power Society highlights that maintaining a pressure drop of no more than 10% can enhance efficiency by up to 15%.

Another effective method is to periodically review and recalibrate valves as part of a preventive maintenance program. Data from a recent industry survey found that regular maintenance schedules could increase a valve's lifespan by as much as 50%, thereby reducing the need for replacements and associated costs. By implementing these strategies, companies can achieve a more efficient hydraulic flow system while simultaneously reducing operational costs.

Best Practices for Regular Maintenance and Inspection of Valves

Regular maintenance and inspection of hydraulic flow control valves are crucial for ensuring their optimal performance and longevity. According to the Hydraulic Institute, improper maintenance can reduce a valve's efficiency by up to 20%, leading to increased operational costs. Regular inspections help to identify issues such as leaks, corrosion, or worn components before they escalate into larger problems that could compromise system integrity. It is recommended to conduct inspections at least quarterly, focusing on the valve's seals, actuators, and overall assembly.

**Tip:** Keep a maintenance log that records the inspection dates, findings, and any repairs made. This will not only help track the valve's performance but also assist in planning future maintenance activities.

Another best practice is to follow manufacturers' guidelines regarding lubrication and cleaning. The American Society of Mechanical Engineers suggests using compatible lubricants to prevent wear and to ensure that the valve operates smoothly. Moreover, addressing any abnormal noises or vibrations during operation can prevent more significant failures in the long run.

**Tip:** Implement a routine preventive maintenance schedule, as studies indicate that well-maintained hydraulic systems can operate with up to 30% greater efficiency, significantly reducing downtime and repair costs.

Hydraulic Flow Control Valves Efficiency Optimization

This bar chart illustrates the efficiency of hydraulic flow control valves based on various maintenance practices. Regular inspection and adherence to best practices can significantly enhance the overall performance and lifespan of the valves.

Innovations in Hydraulic Technology: Future Trends for Efficient Flow Control

The landscape of hydraulic technology is rapidly evolving, with innovative solutions emerging to enhance flow control efficiency. One of the most promising trends is the integration of smart technology into hydraulic systems. By incorporating sensors and advanced algorithms, hydraulic flow control valves can now monitor real-time data, allowing for adaptive adjustments based on operating conditions. This not only improves performance but also reduces energy consumption and operational costs, paving the way for more sustainable hydraulic systems.

Another significant trend is the development of materials and designs that minimize wear and tear, prolonging the life of hydraulic components. Enhanced sealing technologies and lightweight materials are being utilized to ensure better reliability under high-pressure conditions. Additionally, increased focus on modular systems enables easier upgrades and customization, allowing businesses to adapt to changing demands without overhauling entire systems. As these innovations continue to shape the future of hydraulic technology, they promise to drive greater efficiency and performance in flow control applications across various industries.

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

| Parameter | Current Standard | Innovative Solutions | Future Trends |

|---|---|---|---|

| Flow Rate (L/min) | 50 | Smart flow regulation technology | Real-time adaptive control |

| Pressure Rating (bar) | 200 | Advanced materials reducing fatigue | Increased pressure handling up to 300 bar |

| Response Time (ms) | 100 | Microprocessor control systems | Sub-50 ms response time |

| Energy Efficiency (%) | 85 | Variable speed drive integration | Targeting 95% efficiency |

| Maintenance Interval (months) | 6 | Predictive maintenance alerts | Extended 12-month intervals |

Related Posts

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

Ultimate Guide to Mastering Control Flow for Optimal Performance

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

skip to Main Content

skip to Main Content