How to Optimize Hydraulic Flow Control for Maximum Efficiency

In today's industrial landscape, optimizing hydraulic flow control is essential for enhancing system efficiency and performance. Hydraulic flow control systems manage the movement and pressure of fluids, ensuring that machinery operates smoothly and without interruption. With increasing demands for productivity and sustainability, the importance of maximizing efficiency in hydraulic systems cannot be overstated.

This guide will delve into various strategies and techniques designed to refine hydraulic flow control, thereby achieving optimal performance. From the selection of appropriate components to the implementation of advanced control technologies, each aspect contributes to the overall effectiveness of hydraulic systems.

By understanding and applying these principles, businesses can significantly reduce energy consumption, lower operational costs, and extend the lifespan of equipment, making hydraulic flow control a crucial focal point for engineers and operators alike.

Understanding the Basics of Hydraulic Flow Control Systems

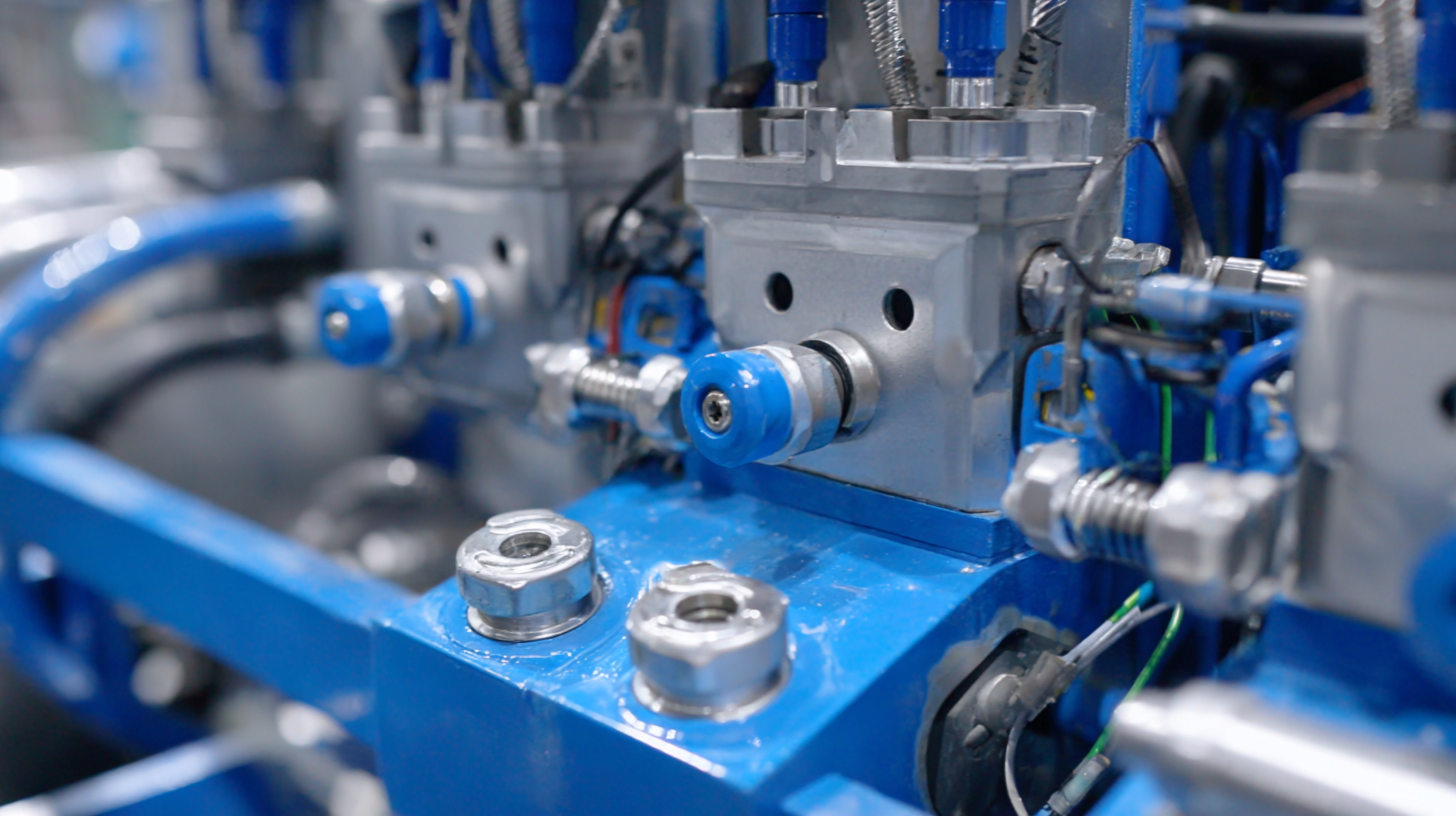

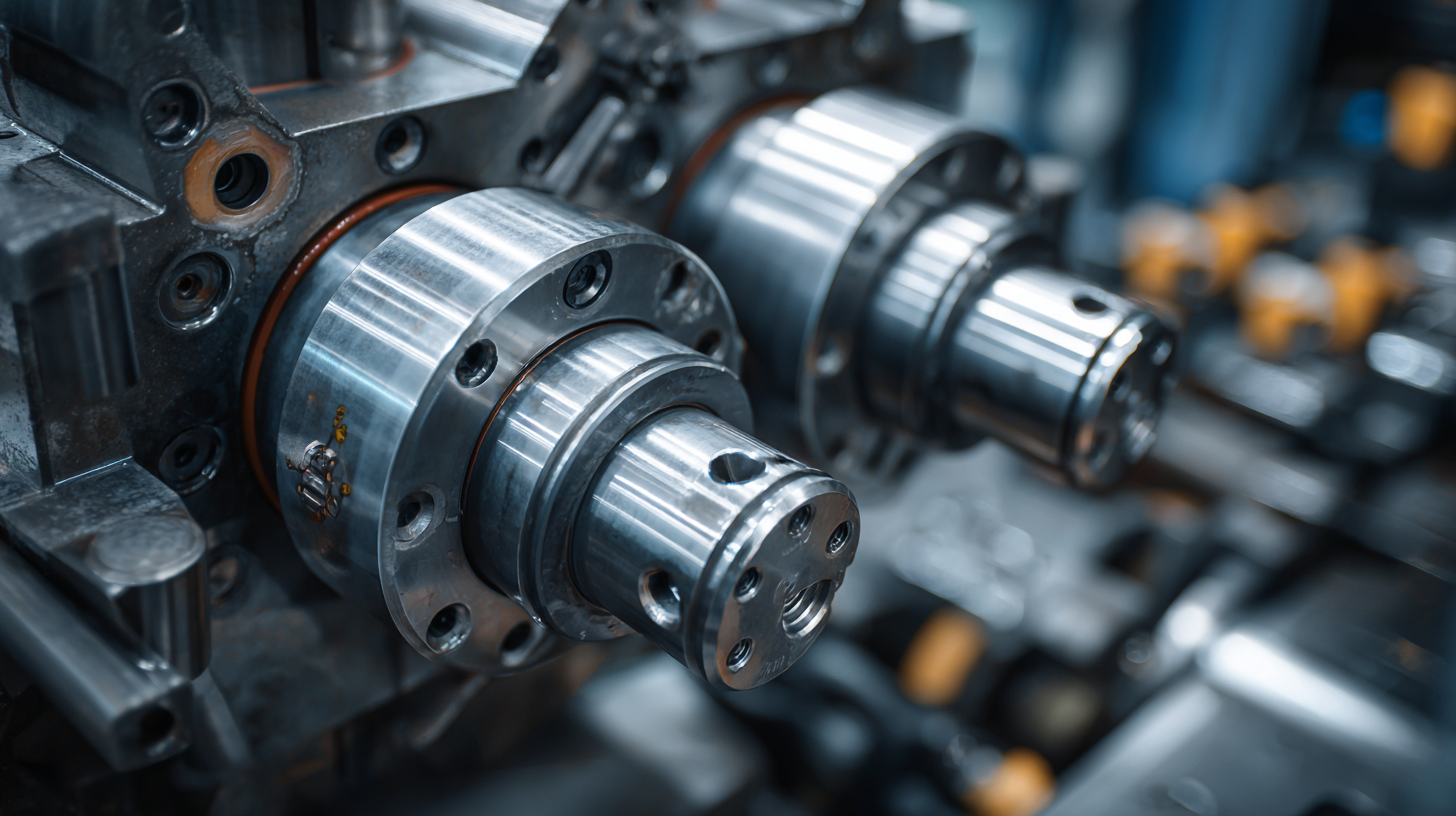

Understanding hydraulic flow control systems is crucial for achieving maximum efficiency in various industrial applications. These systems utilize pressurized fluid to transmit power and control movements, making them essential in machinery such as excavators, forklifts, and agricultural equipment. The basic components include pumps, valves, cylinders, and reservoirs, all of which work together to regulate flow and pressure. Mastering these fundamentals can lead to significant improvements in equipment performance and longevity.

Tips for optimal hydraulic flow control include regular maintenance checks on all components to prevent leaks and ensure smooth operation. Additionally, selecting the right size and type of valves can dramatically enhance response times and energy efficiency. Another effective strategy is to utilize variable displacement pumps, which adjust their output based on demand, thus conserving energy during low-load periods. By focusing on these elements, operators can create a more efficient and responsive hydraulic system.

Moreover, implementing advanced control strategies, such as proportional or servo-controlled valves, can further optimize flow dynamics under varying load conditions. This not only increases precision in motion control but also enhances overall system reliability. By understanding and applying these techniques, organizations can maximize the efficiency of their hydraulic flow control systems and improve their operational capabilities.

How to Optimize Hydraulic Flow Control for Maximum Efficiency

| Component | Function | Efficiency (%) | Maintenance Frequency (months) |

|---|---|---|---|

| Pump | Pressurizes Hydraulic Fluid | 85 | 6 |

| Actuator | Converts Fluid Power to Mechanical Force | 90 | 12 |

| Valves | Controls Flow Direction and Pressure | 80 | 9 |

| Hydraulic Fluid | Transmits Power | 95 | 24 |

| Filter | Removes Contaminants | 92 | 3 |

Identifying Key Factors Affecting Flow Efficiency

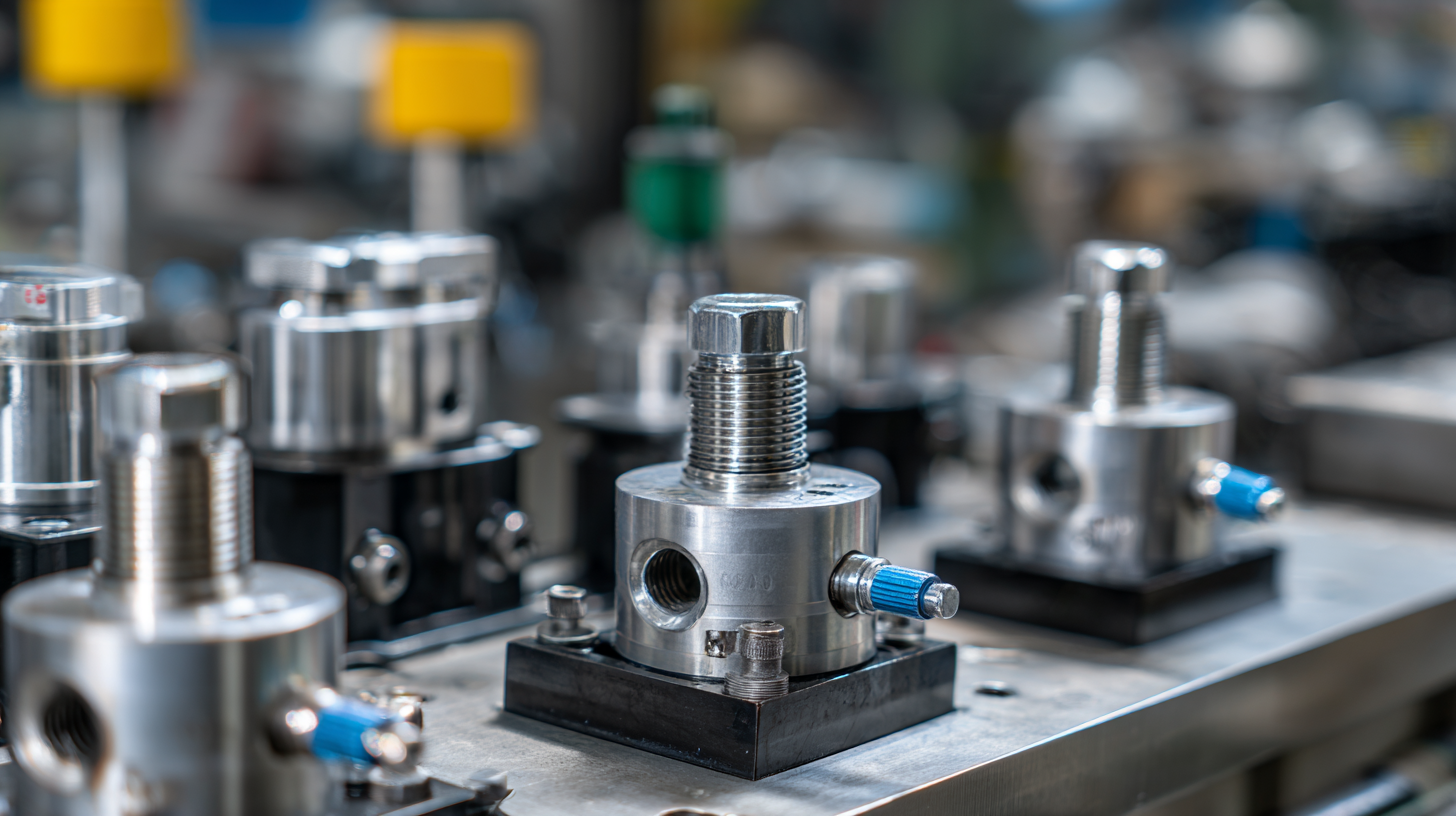

Hydraulic flow control is essential for ensuring maximum efficiency in various industrial applications. Identifying key factors that affect flow efficiency can significantly enhance system performance and energy consumption. One critical factor is the selection of appropriate hydraulic components, such as pumps, valves, and actuators, which should match the system's requirements to minimize energy losses.

Tips: Regular maintenance of hydraulic systems is crucial. Ensure that components are clean and free from contaminants, as dirt buildup can restrict flow and reduce efficiency. Additionally, monitor fluid levels and replace fluids at recommended intervals to maintain optimal viscosity and performance.

Another significant aspect is the design of the hydraulic circuit. An optimized circuit layout can reduce pressure drops and improve flow rates. The use of larger diameter hoses and pipes can facilitate better flow while minimizing bends and long runs that create turbulence.

Tips: Implement flow meters to monitor real-time performance and make adjustments as necessary. This proactive approach can help identify issues before they escalate, ensuring consistent and efficient operation of the hydraulic system.

Optimizing Hydraulic Flow Control for Maximum Efficiency

Implementing Advanced Control Technologies and Solutions

Implementing advanced control technologies in hydraulic systems is crucial for achieving maximum efficiency and performance. Recent studies indicate that integrating smart sensors and real-time data analytics can lead to efficiency improvements of up to 30% in hydraulic flow management. By leveraging these technologies, operators can better monitor system parameters, detect anomalies, and adjust flow rates dynamically, thereby optimizing energy consumption and reducing operational costs.

Moreover, the adoption of model predictive control (MPC) techniques has shown significant promise in enhancing the precision of flow control. A report from the Hydraulic Institute highlights that systems utilizing MPC can minimize flow fluctuations and maximize response times, resulting in a further 20% enhancement in system performance when compared to traditional control methods. As the industry increasingly embraces automation and AI-driven approaches, the potential for achieving greater efficiency in hydraulic flow control becomes a tangible reality. These advancements not only streamline processes but also contribute to overall sustainability goals by reducing energy waste and lowering emissions.

Regular Maintenance Practices for Optimized Hydraulic Systems

Regular maintenance practices are crucial for optimizing hydraulic systems, ensuring they operate efficiently and prolonging their lifespan. According to the International Fluid Power Society, routine checks and maintenance can reduce unplanned downtime by up to 45%, which significantly enhances system reliability.

Regular inspections should include checking fluid levels, testing for leaks, and monitoring pressure levels to ensure they are within manufacturers' specified ranges. By performing these tasks consistently, the performance of hydraulic systems can be maximized, reducing the risk of catastrophic failures.

Moreover, ensuring proper filtration is a vital maintenance practice that affects hydraulic flow control. The National Fluid Power Association reports that up to 70% of hydraulic system failures can be attributed to contamination. Utilizing high-quality filters and replacing them at regular intervals can drastically decrease the likelihood of dirt and debris entering the system, leading to smoother hydraulic flow and improved efficiency. Additionally, implementing a fluid analysis program can help identify potential issues before they escalate, thus maintaining optimal performance and reducing overall operational costs.

Analyzing Performance Metrics to Enhance Flow Control Efficiency

Hydraulic flow control optimization is crucial for enhancing efficiency across various applications. Analyzing performance metrics is essential in this optimization process. By focusing on parameters such as flow rate, pressure drop, and energy consumption, engineers can identify bottlenecks and inefficiencies in hydraulic systems. Utilizing real-time data analytics enables teams to monitor these metrics continuously and adjust control strategies accordingly, ensuring that the system operates at peak performance.

In sectors like energy storage, performance metrics play a vital role. For example, the development of all-vanadium flow batteries showcases the importance of analyzing key material properties to maximize the efficiency of energy storage systems. Features like safety, longevity, and operational flexibility are critical in determining the effectiveness of these technologies. Similarly, in manufacturing, leveraging data to refine processes and improve operational efficiency is paramount. By systematically analyzing performance metrics, manufacturers can implement targeted adjustments that yield significant improvements in productivity and cost-effectiveness. Through disciplined analysis and optimization, industries can achieve maximum efficiency in their hydraulic flow control systems.

Related Posts

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

How to Optimize Your System with Automated Valves for Maximum Efficiency

-

10 Essential Flow Control Valves Every Industry Should Consider

skip to Main Content

skip to Main Content