Understanding the Importance of Hydraulic Pressure Relief Valves in Industrial Applications

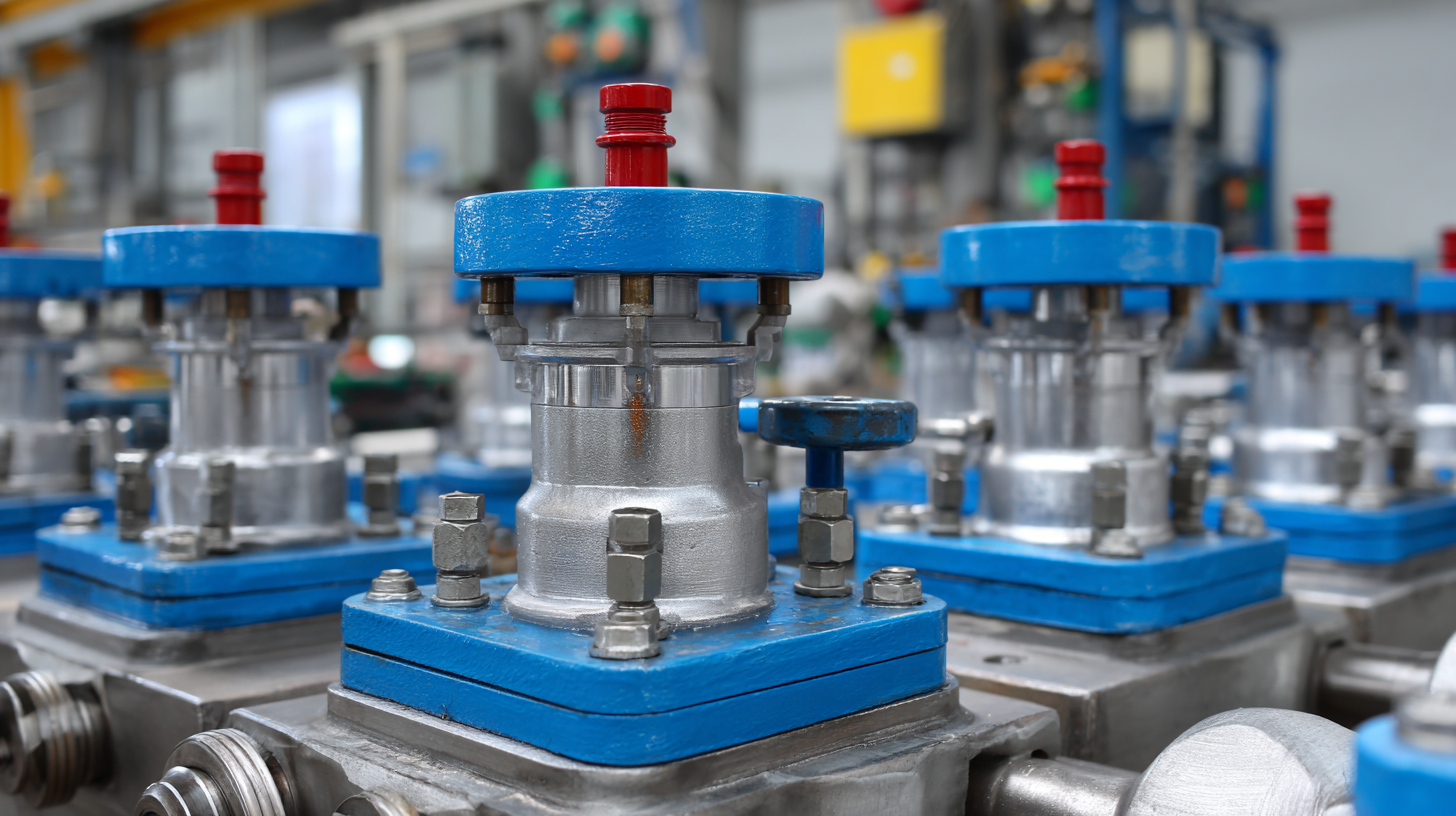

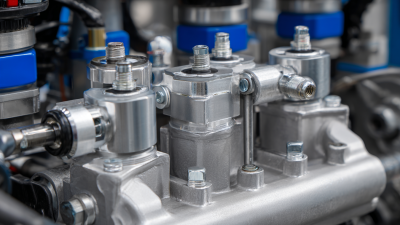

In the realm of industrial applications, hydraulic pressure relief valves play a crucial role in maintaining system safety and functionality. According to a report by the International Fluid Power Society, over 30% of industrial hydraulic system failures are attributed to pressure imbalances, highlighting the necessity of effective pressure management solutions. Hydraulic pressure relief valves serve as a safeguard, preventing pressure build-up that can lead to catastrophic equipment failure or hazards.

In the realm of industrial applications, hydraulic pressure relief valves play a crucial role in maintaining system safety and functionality. According to a report by the International Fluid Power Society, over 30% of industrial hydraulic system failures are attributed to pressure imbalances, highlighting the necessity of effective pressure management solutions. Hydraulic pressure relief valves serve as a safeguard, preventing pressure build-up that can lead to catastrophic equipment failure or hazards.

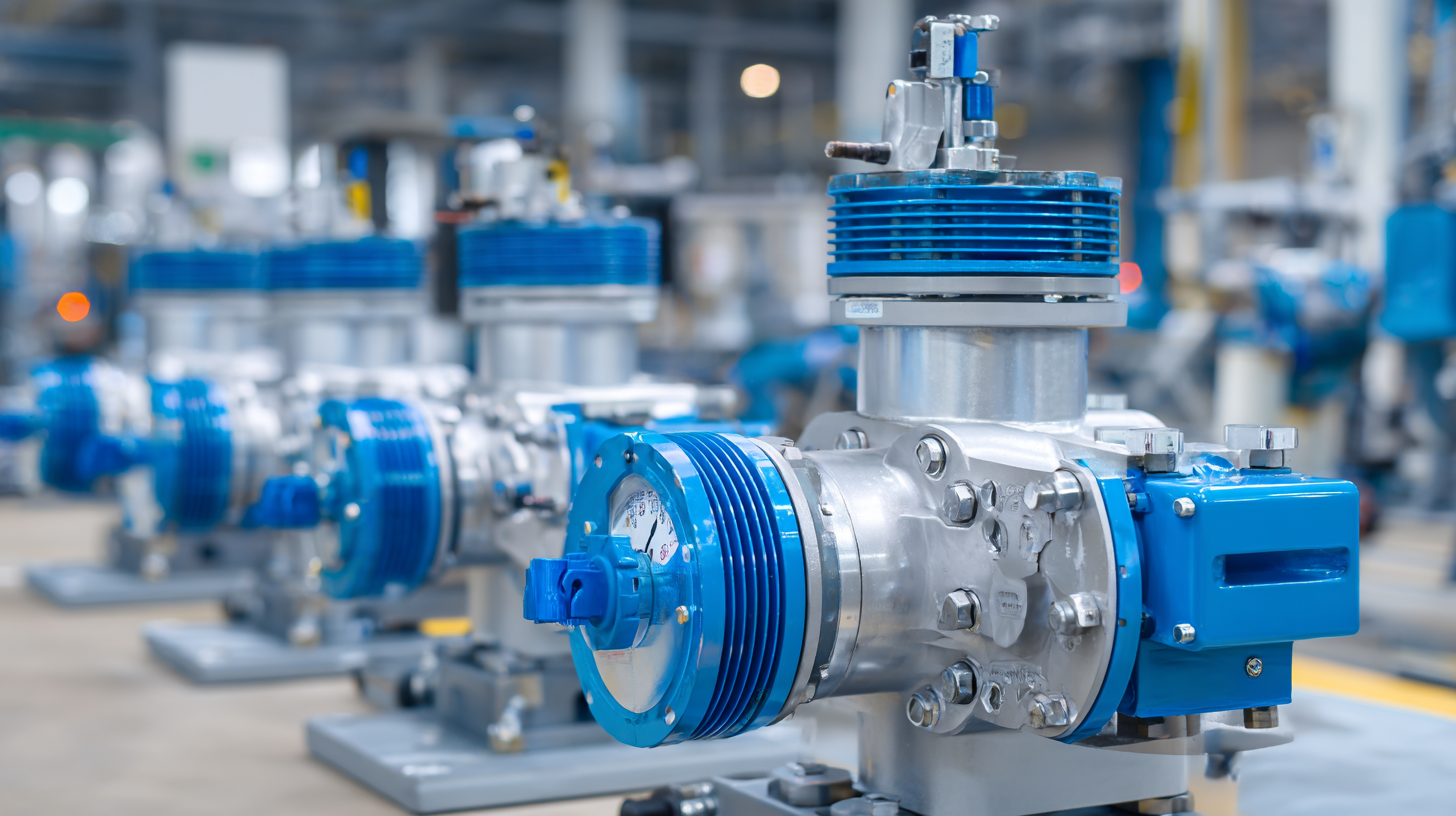

The global hydraulic valve market size was valued at approximately $5.8 billion in 2022, with a projected growth rate of 5.1% annually through 2030, underscoring the increasing reliance on advanced hydraulic technologies. As industries continue to evolve, ensuring the reliability and efficacy of hydraulic systems through the strategic implementation of hydraulic pressure relief valves becomes paramount, underscoring their essential role in safeguarding operational integrity and enhancing overall performance.

The Fundamental Role of Hydraulic Pressure Relief Valves in System Safety

Hydraulic pressure relief valves play a crucial role in maintaining the safety and efficiency of industrial hydraulic systems. According to a report by the International Fluid Power Society, nearly 30% of hydraulic system failures can be traced back to inadequate pressure regulation. These relief valves are designed to prevent excessive pressure buildup, which can lead to catastrophic equipment failure, causing significant downtime and financial losses. By systematically releasing pressure when it exceeds a predetermined threshold, they protect not only the machinery but also the operators working in potentially hazardous environments.

Moreover, the American National Standards Institute (ANSI) emphasizes that proper installation and maintenance of hydraulic pressure relief valves can enhance system reliability by up to 50%. In critical applications such as aerospace, automotive manufacturing, and construction, these valves serve as the first line of defense against pressure surges caused by sudden operational changes or system malfunctions. Ensuring these components function optimally not only safeguards equipment but also upholds compliance with industry safety standards, thereby protecting personnel and minimizing liability risks for companies.

Key Benefits of Implementing Pressure Relief Valves in Industrial Equipment

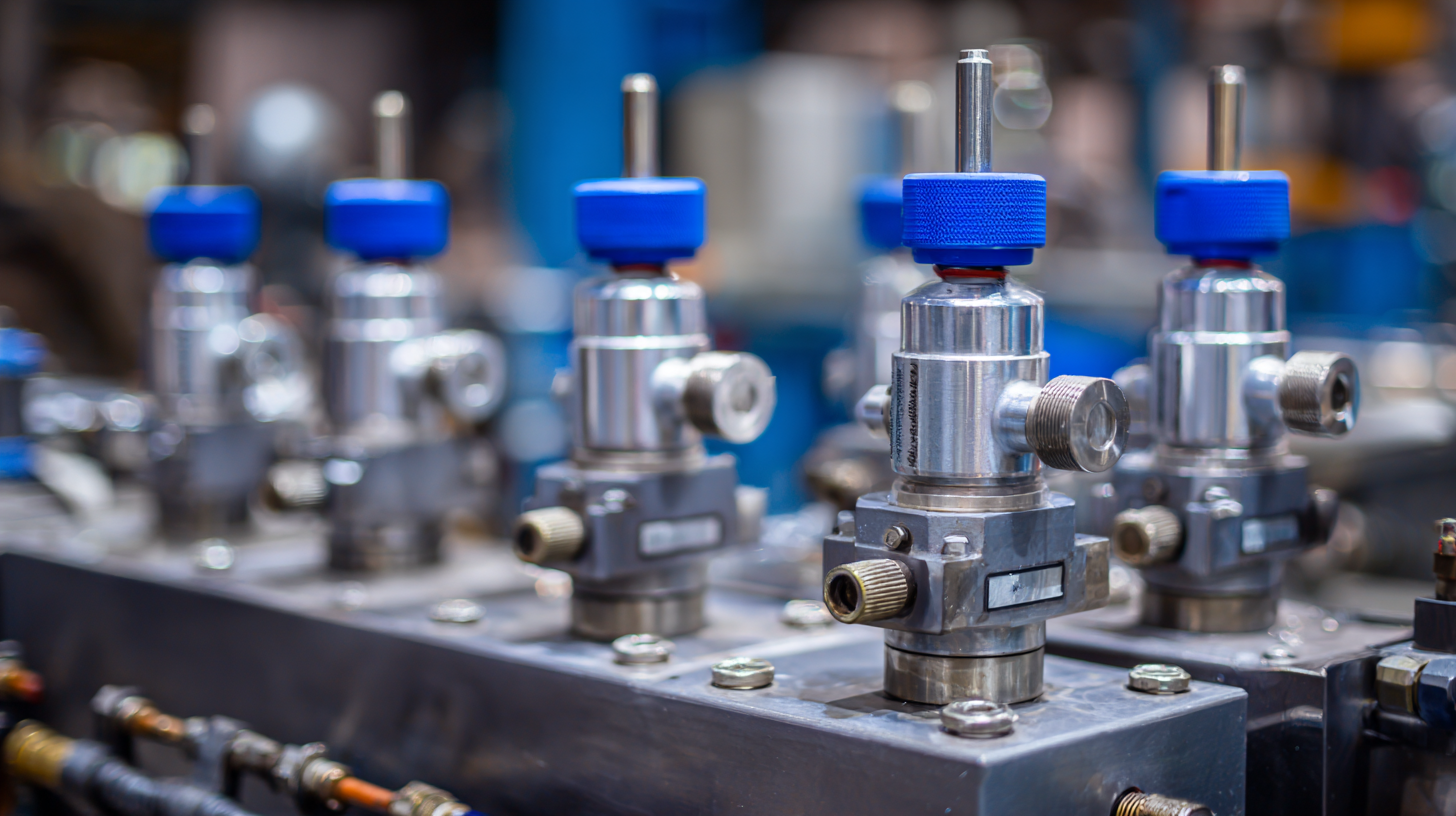

Hydraulic pressure relief valves play a critical role in maintaining the safety and efficiency of industrial applications. According to a report by the Hydraulic Institute, improperly controlled hydraulic pressure can lead to equipment failure in up to 30% of hydraulic systems. This emphasizes the necessity of implementing these valves to prevent potential malfunctions and hazards. Pressure relief valves are designed to automatically release excess pressure, ensuring that machinery operates within safe limits and significantly reducing the risk of catastrophic failures.

One of the key benefits of using pressure relief valves is the enhancement of system longevity. By mitigating the dangers associated with excessive pressure, these valves protect critical components, potentially extending service life by up to 50%, as noted in studies by the American Society of Mechanical Engineers (ASME). Furthermore, pressure relief valves can improve operational efficiency by maintaining consistent pressure levels, leading to better performance and reduced energy costs.

**Tip:** Regular maintenance of hydraulic pressure relief valves is essential. It is advisable to check them every six months to ensure they are functioning correctly and to prevent costly downtimes. Additionally, consider using pressure relief valves with adjustable settings to accommodate varying operational demands, which can maximize both safety and efficiency in your industrial equipment.

Understanding the Importance of Hydraulic Pressure Relief Valves in Industrial Applications

| Benefit | Description | Example Application |

|---|---|---|

| Safety Enhancement | Prevents equipment failure and protects workers from hydraulic shocks. | Construction machinery |

| Equipment Longevity | Reduces wear and tear on hydraulic components by controlling pressure levels. | Manufacturing robots |

| Operational Efficiency | Maintains optimal pressure for smoother operation and less downtime. | Hydraulic presses |

| Cost Savings | Minimizes repair costs by preventing overloads and system failures. | Oil and gas equipment |

| Compliance with Standards | Helps organizations meet safety and environmental regulations. | Chemical processing plants |

Common Applications of Hydraulic Pressure Relief Valves in Various Industries

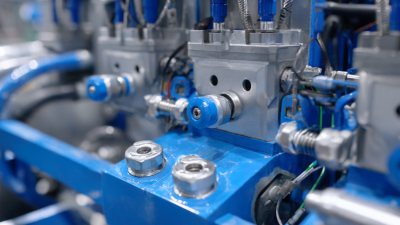

Hydraulic pressure relief valves are crucial components across various industrial applications, playing a vital role in safeguarding equipment and ensuring operational efficiency. In sectors such as manufacturing, construction, and mining, these valves prevent excessive pressure buildup that can lead to catastrophic failures. According to a report by the International Fluid Power Society, more than 30% of hydraulic system failures are attributed to inadequate pressure regulation, highlighting the necessity of these valves.

In the automotive industry, hydraulic pressure relief valves are employed in braking systems to maintain safe operating pressures. Moreover, in agricultural machinery, they protect hydraulic systems from overloads during heavy lifting or plowing activities. Research indicates that industries utilizing these valves can enhance their equipment longevity by up to 40%, significantly reducing maintenance costs and downtime.

Tips: Regularly inspect hydraulic systems for signs of wear or damage to the pressure relief valves, as early detection can prevent more severe failures. Additionally, ensure that the relief valve settings are calibrated according to the manufacturer's specifications to optimize system performance. Adopting a proactive maintenance routine can lead to substantial operational savings in the long run.

Risk Mitigation: How Pressure Relief Valves Protect Equipment and Personnel

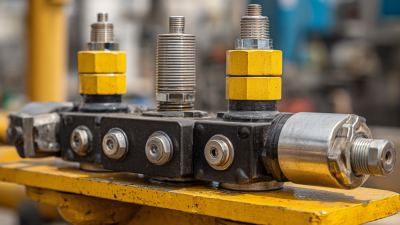

Hydraulic pressure relief valves play a pivotal role in industrial applications by mitigating risks associated with excessive pressure buildup. These valves are designed to open and release pressure when it exceeds a certain threshold, preventing potential equipment failures or catastrophic accidents. By maintaining safe pressure levels, they protect not only the machinery involved but also the operators and personnel working in the vicinity. The timely activation of these valves ensures that hydraulic systems operate efficiently and safely, making them an indispensable component in various industries.

The failure of hydraulic systems often results in severe damage and can lead to dangerous situations, including explosions or equipment malfunction. Pressure relief valves serve as a first line of defense against such risks by ensuring that pressure does not rise to unsafe levels. Regular maintenance and monitoring of these valves are crucial; their reliability can mean the difference between operational continuity and serious incidents. In essence, investing in quality hydraulic pressure relief valves is essential for the protection and safety of both equipment and personnel in industrial settings.

Maintenance Best Practices for Hydraulic Pressure Relief Valves in Operations

Proper maintenance of hydraulic pressure relief valves is crucial for ensuring the efficiency and safety of industrial operations. Regular inspections should be conducted to check for signs of wear, corrosion, or leaks. This preventive approach helps identify potential issues before they escalate, thereby reducing downtime and repair costs. Technicians should refer to the manufacturer’s guidelines for specific maintenance schedules and procedures, which often include cleaning, functionality testing, and recalibration of the valves.

In addition to routine inspections, it is vital to keep accurate records of maintenance activities. Documenting the history of valve performance and any repairs made allows for better tracking of patterns that might indicate recurring problems. Moreover, ensuring that the surrounding environment is free from contaminants can significantly improve the lifespan of hydraulic pressure relief valves. Utilizing high-quality fluids and keeping the hydraulic system clean further supports optimal valve operation, enhancing overall system reliability and performance in industrial applications.

Related Posts

-

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Ultimate Guide to Mastering Control Flow for Optimal Performance

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

skip to Main Content

skip to Main Content