Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

In the realm of industrial machinery, the efficiency and reliability of operations heavily rely on the intricate components that manage fluid dynamics. One of the most critical components in hydraulic systems is hydraulic flow control valves, which regulate the flow rate and direction of hydraulic fluid, thereby influencing the overall performance and longevity of machinery. According to a report by the Hydraulic Institute, optimized hydraulic systems can enhance operational efficiency by up to 30%, significantly reducing energy consumption and operational costs.

As industries strive for improved performance and sustainability, the role of hydraulic flow control valves has become increasingly paramount. These valves not only ensure precision in movement and speed but also play a crucial part in maintaining system stability and safety. An analysis from the International Journal of Fluid Mechanics highlights that poorly managed hydraulic systems can lead to inefficiencies, resulting in an average increase of 20% in maintenance costs due to unplanned downtimes.

Thus, understanding the mechanisms and benefits of hydraulic flow control valves is essential for modern machinery performance and reliability in various applications, from manufacturing to construction.

Understanding the Role of Hydraulic Flow Control Valves in Machinery

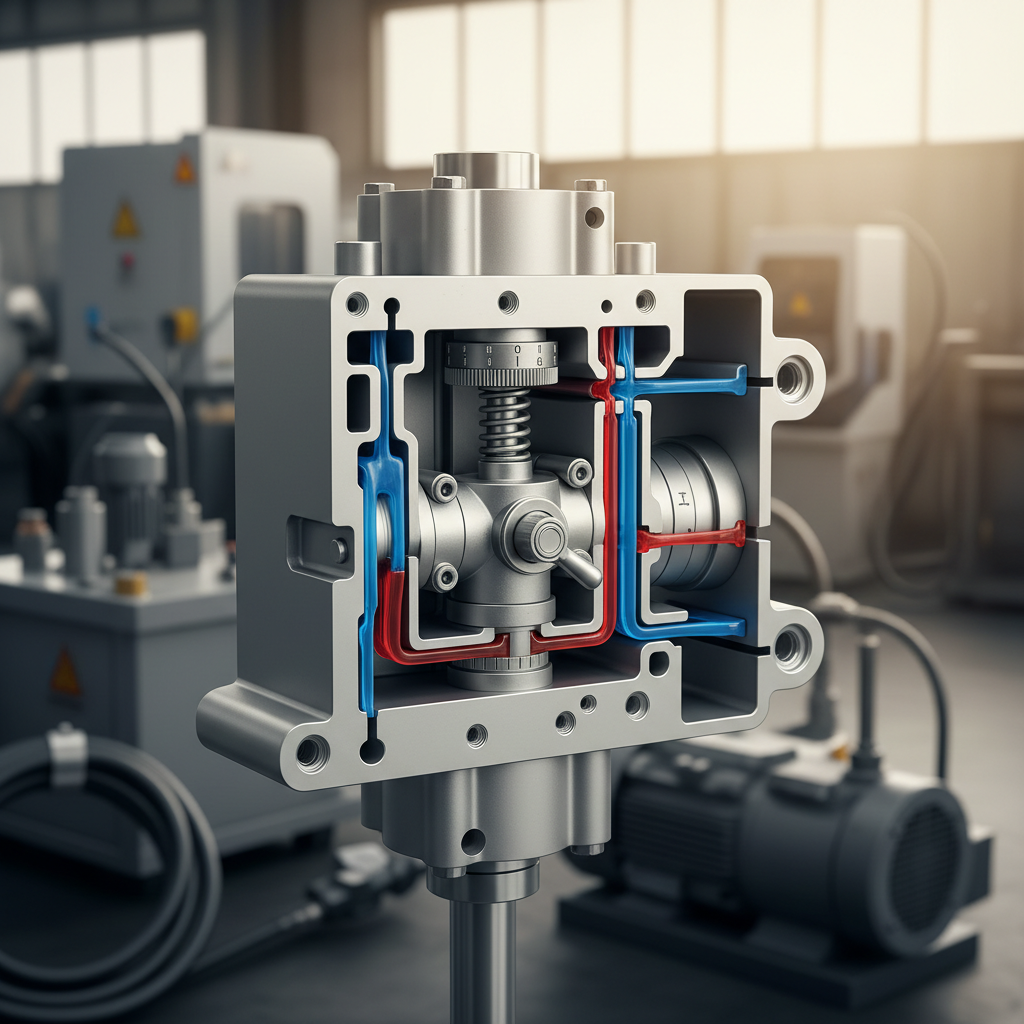

Hydraulic flow control valves play a critical role in ensuring optimal performance across various machinery sectors, primarily through their ability to regulate fluid flow. By precisely controlling the rate of hydraulic fluid entering different components, these valves can help maintain desired operational speeds and forces. This regulation is essential not only for efficiency but also for the safety and longevity of equipment by preventing potential overloads and system failures.

The functioning of hydraulic flow control valves involves adjusting the flow path and volume, which in turn influences the actuation of hydraulic cylinders and motors. Such control enables machinery to perform tasks with remarkable accuracy, ultimately improving productivity. Moreover, by facilitating smoother operations, these valves minimize hydraulic shock and noise, contributing to a more stable and quieter work environment.

In conclusion, understanding the function of hydraulic flow control valves reveals their indispensable contribution to machinery performance, underscoring their necessity in modern industrial applications.

Types of Hydraulic Flow Control Valves and Their Applications

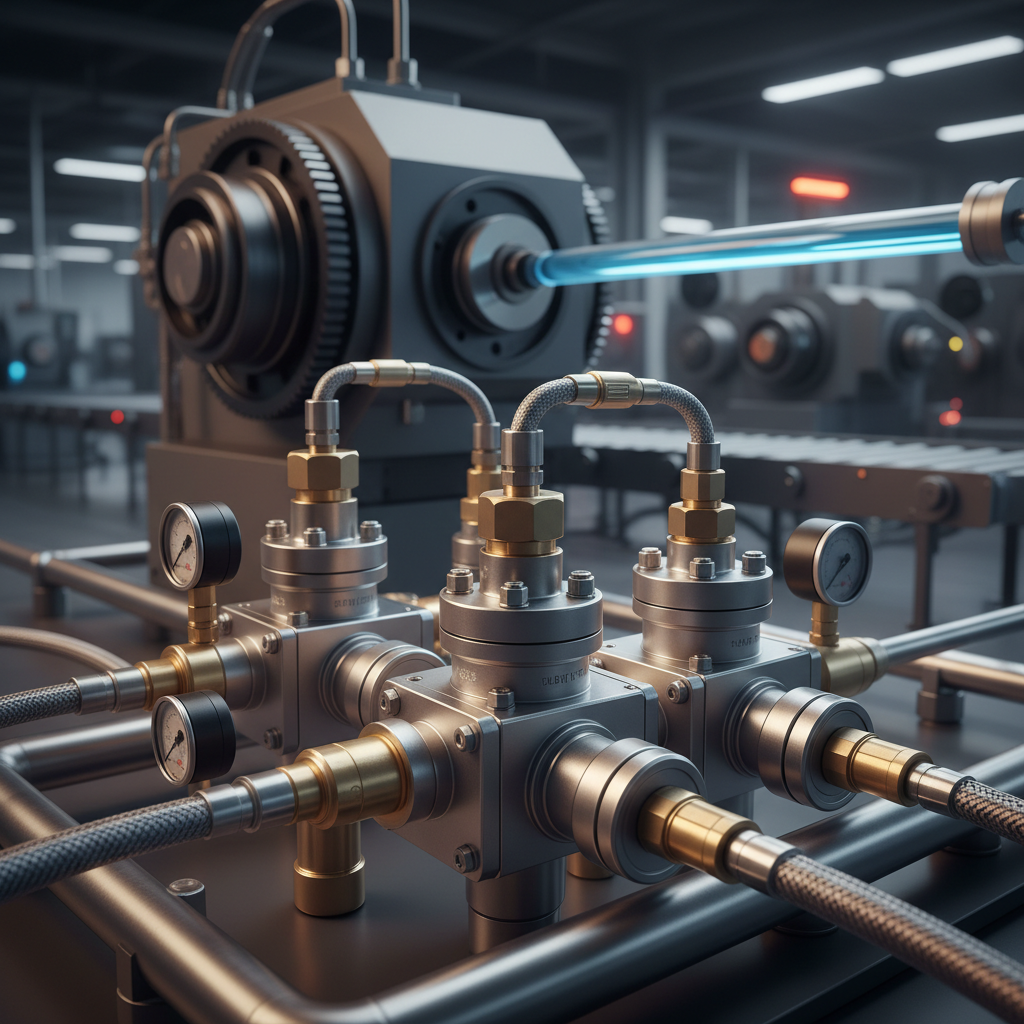

Hydraulic flow control valves are crucial components in a multitude of industrial applications, optimizing the performance of machinery by regulating the flow of hydraulic fluid. These valves come in various types, each serving unique functions tailored to specific operational requirements. The most common types include pressure control valves, throttle valves, and flow dividers. Pressure control valves maintain system pressure, ensuring stability and preventing damage due to excessive hydraulic force. Throttle valves, on the other hand, precisely manage fluid flow rates, enabling fine control over machinery speed and movement.

In terms of applications, flow control valves find utility in industries ranging from construction to manufacturing. According to a report by ResearchAndMarkets.com, the global hydraulic valves market is projected to reach $12.7 billion by 2026, highlighting the growing reliance on these components for efficient machinery operation. Industries such as automotive manufacturing use throttle valves to ensure accurate movement of robotic arms, while construction equipment often employs pressure control valves to manage the operation of powerful hydraulic arms and lifts. By selecting the appropriate valve type for specific applications, organizations can significantly enhance the reliability and efficiency of their hydraulic systems.

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

| Type of Hydraulic Flow Control Valve | Description | Applications | Advantages |

|---|---|---|---|

| Throttle Valve | Regulates flow rate by varying the orifice size. | Machine tool operations, Agricultural equipment. | Simple design, Easy to adjust flow rate. |

| Flow Control Valve | Maintains consistent flow regardless of pressure changes. | Construction equipment, Hydraulic lifts. | Stable performance, Reduces system stress. |

| Pressure Compensated Flow Control Valve | Adjusts flow rate automatically with the pressure changes. | Mobile equipment, Industrial machinery. | Improves efficiency, Ensures optimal system performance. |

| Electro-Hydraulic Flow Control Valve | Combines hydraulic and electronic control for precision. | Robotic systems, CNC machines. | High precision, Programmable control. |

| Check Valve | Allows flow in one direction and prevents backflow. | Hydraulic circuits, Fluid transfer systems. | Protects system integrity, Simple operation. |

Key Features to Look for in Hydraulic Flow Control Valves

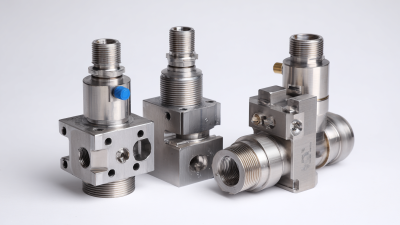

When selecting hydraulic flow control valves, several key features should be prioritized to ensure optimal machinery performance. Firstly, the valve's adjusting mechanism is crucial. Look for valves that offer precision in flow regulation. A finely tuned adjustment capability allows operators to maintain consistent flow rates, thereby enhancing the efficiency of hydraulic systems. Additionally, consider the valve's response time; rapid response ensures that the system can adapt quickly to changing demands, minimizing pressure surges and improving performance stability.

Another important feature is the valve's construction materials. Durable components resistant to wear and corrosion enhance the lifespan and reliability of the valve, crucial for operations in harsh environments. Furthermore, thermal stability is vital, ensuring that the valve maintains its performance under varying temperature conditions. Lastly, compatibility with existing systems is essential; check if the valve can integrate seamlessly into your current hydraulic setup without requiring extensive modifications. These features collectively contribute to the effective management of hydraulic flow, leading to enhanced machinery reliability and productivity.

Hydraulic Flow Control Valves Performance Metrics

The chart above illustrates the response time of various hydraulic flow control valves. Valve A shows the quickest response time, while Valve C has the longest response time. Understanding these metrics is vital for ensuring optimal machinery performance.

Best Practices for Installing and Maintaining Hydraulic Flow Control Valves

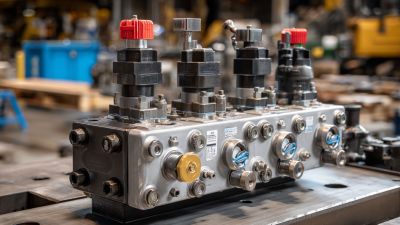

Proper installation and maintenance of hydraulic flow control valves are pivotal for enhancing machinery performance. According to the International Fluid Power Society, an estimated 30% of hydraulic system failures can be traced back to improper valve setup or neglect. To ensure optimal operation, it's vital to adhere to manufacturer guidelines and industry best practices. This includes aligning the valves correctly, ensuring they are free from debris, and utilizing proper torque settings during installation.

Tips: Regularly inspect hydraulic flow control valves for signs of wear, such as leaks or inconsistent performance. Implementing a preventive maintenance schedule can extend the lifespan of these components significantly. Industry reports suggest that regular maintenance can reduce failure rates by up to 25%, ultimately leading to cost savings and increased machinery reliability.

Additionally, utilizing the right fluid type is crucial. Research indicates that using fluids that meet standard viscosity requirements can reduce energy loss by 10-15%. Ensure to choose hydraulic fluids that are compatible with your systems to prevent damaging the valves and other hydraulic components. By following these practices, operators can ensure that hydraulic systems function at peak efficiency, resulting in better overall performance.

Common Issues with Hydraulic Flow Control Valves and How to Troubleshoot Them

Hydraulic flow control valves are vital for maintaining optimal machinery performance, yet they are prone to various common issues that can affect their efficiency. One prevalent problem is clogging, often caused by contaminants in the hydraulic fluid. According to a report by the International Fluid Power Society, approximately 70% of hydraulic failures are linked to fluid contamination. Regular maintenance, including fluid filtration and regular checks of the system, can help in mitigating this issue.

Another common issue is improper valve adjustment, which can lead to inconsistent flow rates and erratic machine performance. According to studies published in the Journal of Hydraulic Engineering, improper settings in flow control valves can result in up to 30% inefficiency in hydraulic systems. Ensuring that valves are correctly calibrated and regularly checked can prevent this inefficiency.

**Tip:** Always utilize high-quality hydraulic fluids that meet the manufacturer's specifications to minimize contamination.

**Tip:** Implement a routine maintenance schedule to regularly inspect and adjust hydraulic flow control valves, which will help ensure consistent performance and longevity of your machinery.

Related Posts

-

How to Choose the Right Hydraulic Check Valve for Your System

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

skip to Main Content

skip to Main Content