Why Hydraulic Continental Systems Are Essential for Modern Engineering?

In the realm of modern engineering, hydraulic continental systems play a pivotal role. These systems are designed for efficiency and precision. According to a recent report by the Engineering Sector Analysis, 75% of current industrial projects rely on hydraulic technologies. This reliance underscores the importance of hydraulic continental systems.

Expert James Caldwell, a leading engineer in this field, states, "Hydraulic continental systems enable sustainability and innovation in engineering." His insights reflect a growing trend towards environmentally-friendly practices. The adaptability of these systems fuels advancements across sectors, from construction to automotive.

However, challenges remain. Implementation costs can be high, and training is essential. Companies must continuously evaluate their investments in hydraulic continental systems to ensure maximum efficiency. Balancing innovation with financial considerations is crucial. The future of engineering rests on how well the industry addresses these complexities.

The Definition and Functionality of Hydraulic Continental Systems

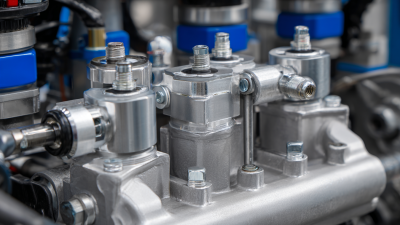

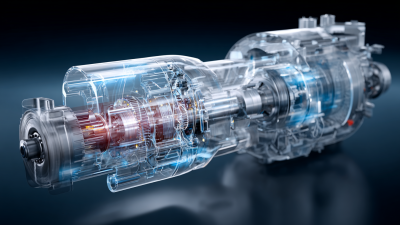

Hydraulic Continental Systems play a vital role in modern engineering. These systems rely on fluid mechanics to transmit power. Their design allows for efficient energy transfer in various applications. In construction, they lift heavy materials with ease and precision. This capability is crucial for large-scale projects that demand reliability.

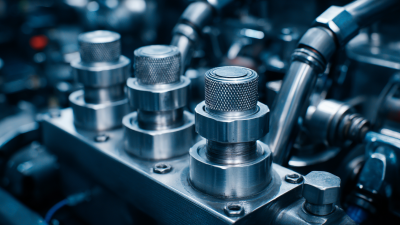

The functionality of these systems is impressive. They consist of pumps, cylinders, and valves, all working in harmony. Each component must function optimally for smooth operation. However, inefficiencies can arise. For instance, leaks can disrupt workflows and lead to costly delays. Regular maintenance is necessary to address these issues.

Moreover, engineers face challenges when designing hydraulic systems. Balancing power and safety can be tricky. Overloading systems can cause failures, leading to hazardous situations. Despite these concerns, hydraulic systems remain a cornerstone of engineering innovation. They enable advancements in various fields, like aerospace and automotive industries. Understanding their workings is essential for improving design and safety standards.

Key Advantages of Hydraulic Systems in Modern Engineering

Hydraulic systems play a crucial role in modern engineering. They provide significant advantages that enhance efficiency and productivity across various industries. According to a recent report by the International Society for Automation, hydraulic systems can increase operational efficiency by up to 25%. This efficiency stems from their ability to easily generate large amounts of force with minimal energy input.

One key advantage of hydraulic systems is their precision. Engineers utilize these systems for tasks requiring exact movements, such as in robotics and manufacturing. A report from the American Society of Mechanical Engineers highlights that hydraulic actuators have a response time of less than 0.5 seconds, allowing for rapid adjustments. This precision translates into improved safety and reduced material waste, yet engineers often face challenges when there are system leaks, which can lead to performance issues or costly repairs.

Another noteworthy aspect is flexibility. Hydraulic systems can adapt to various applications, making them suitable for construction, automotive, and aerospace industries. However, the complexity of these systems can be a double-edged sword. Advanced control systems may enhance performance but increase maintenance demands. Studies indicate that up to 70% of hydraulic issues are attributed to incorrect maintenance. The need for training and awareness is essential to avoid pitfalls that could undermine the benefits these systems offer.

Applications of Hydraulic Continental Systems in Various Industries

Hydraulic Continental Systems play a crucial role across various industries. In construction, they power heavy machinery, enabling precise movements. These systems help lift, dig, and transport materials efficiently. A robust hydraulic system ensures the smooth operation of cranes and excavators. Many companies rely on these systems to enhance productivity.

In the manufacturing sector, hydraulic systems drive equipment like presses and injection molding machines. This allows for tight tolerances and high production rates. They provide the necessary force for shaping materials. However, maintaining these systems can be challenging. Regular checks are essential to avoid breakdowns and costly repairs.

Tip: Regular maintenance can extend the lifespan of hydraulic systems. Schedule inspections to ensure peak performance. In the automotive industry, hydraulic braking systems are pivotal for safety and control. They compress brake fluid, providing quick responses during emergencies. Still, some vehicles fall short on hydraulic system reliability. Addressing these flaws is crucial for driver safety.

Applications of Hydraulic Continental Systems in Various Industries

Challenges and Limitations of Hydraulic Systems in Engineering Practices

Hydraulic systems play a critical role in modern engineering. However, they also face numerous challenges and limitations. One major challenge is fluid leakage. Even minor leaks can lead to significant efficiency losses. Engineers must monitor and maintain these systems carefully to minimize such issues.

Another limitation is the system's weight. Hydraulic components can be heavy and bulky. This can affect the overall design of engineering projects. Weight reduction strategies are essential but can introduce new risks. Balancing performance with weight is a constant struggle in hydraulic system design.

Tips for engineers: always account for potential fluid loss in your calculations. Regular maintenance inspections are a must. Additionally, consider alternative materials that can reduce weight without sacrificing strength. Embrace innovation but remain cautious of its implications. It's vital to question standard practices and seek improvements constantly. Adapting to new technologies while addressing inherent limitations will pave the way for future advancements.

Why Hydraulic Continental Systems Are Essential for Modern Engineering? - Challenges and Limitations of Hydraulic Systems in Engineering Practices

| Dimension | Description | Challenges | Limitations |

|---|---|---|---|

| Efficiency | Hydraulic systems offer high power-to-weight ratios and can be very efficient in energy transmission. | Potential for energy loss due to heat generation and fluid leakage. | Efficiency can diminish over time with wear and tear. |

| Control | Hydraulic systems provide precise control over movements and forces. | Complex feedback and control systems can be difficult to implement optimally. | Requires careful calibration to maintain precision. |

| Durability | Built to withstand tough conditions, hydraulic systems can be very durable with proper maintenance. | Subject to degradation of seals and hoses that can lead to system failure. | Maintenance is crucial to preventing costly downtime. |

| Speed | Hydraulic systems can achieve rapid actuation, with sudden changes in movement speed. | Acceleration can lead to jerk and instability in some applications. | Overly rapid movements may require additional damping mechanisms to manage. |

| Maintenance | Regular maintenance ensures long-term performance and reliability. | Maintenance can be resource-intensive and requires skilled technicians. | Complexity of systems can lead to longer repair times during failures. |

Future Trends and Innovations in Hydraulic Continental Technology

The landscape of hydraulic continental technology is evolving rapidly. Innovations are emerging, reshaping engineering practices. Recent reports indicate that the hydraulic systems market is expected to reach $64 billion by 2025, driven by demand for automation and efficiency. This growth highlights the critical role hydraulic systems play in sectors like construction and manufacturing.

One exciting trend is the integration of IoT in hydraulic systems. Sensors that monitor fluid levels and pressure can provide real-time data. This integration enhances efficiency but can also introduce challenges. Sometimes, the data can be overwhelming. Companies often struggle to manage and analyze this influx of information. Furthermore, while hydraulic systems are generally reliable, they still face issues like leaks and maintenance costs.

Sustainability is another focal point. The push for eco-friendly solutions is reshaping hydraulic designs. Biodegradable fluids are gaining traction, but the transition remains slow. Inconsistencies in performance and costs can hinder widespread adoption. Digital twins, simulating real-world scenarios, help predict performance but require significant investment. As the industry advances, ensuring these innovations align with efficiency and sustainability goals remains a quest requiring careful consideration.

Related Posts

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring the Future of Fluid Power Hydraulics in Innovative Industries

-

Exploring the Future: Top Fluid Power Hydraulics Trends for 2025+

skip to Main Content

skip to Main Content