Essential Guide to Understanding Hydraulics Products for Everyday Applications

In today's world, hydraulics products play a crucial role in a wide array of everyday applications, from industrial machinery to automotive systems. Understanding the types and functionalities of these products is essential for anyone looking to enhance operational efficiency or solve performance challenges. Hydraulics technology harnesses the power of fluid mechanics to transmit force, providing a means to control movement and energy transfer through pressurized liquids. This guide aims to demystify the various categories of hydraulics products, exploring their unique features, common uses, and the underlying principles that govern their operation. By gaining a clearer understanding of these components, users can make informed decisions whether they are involved in engineering, maintenance, or simply curious about how hydraulics impacts their daily lives.

The Fundamentals of Hydraulics: Key Principles and Mechanisms Explained

Hydraulics is a critical field that involves the control and transmission of energy through fluid power systems. Understanding the key principles and mechanisms of hydraulics is essential, especially for applications in various industries. For instance, recent research has highlighted the importance of hydraulic excavator buckets, which are integral components of construction machinery. By analyzing the strength and fatigue of these buckets under different operational conditions, engineers can enhance their design for improved performance and longevity.

In addition to excavators, monitoring systems such as hydraulic columns in coal mining operations exemplify the need for precision in hydraulic applications. The development of high-precision stress monitoring methods for hydraulic columns enables real-time oversight, which is vital for maintaining safety and efficiency. Furthermore, innovative approaches like deep learning frameworks for anomaly detection serve to strengthen hydraulic support systems by identifying potential failures before they become critical, showcasing the modern integration of technology and hydraulics.

Top 5 Hydraulic Fluid Types and Their Impact on Performance

Hydraulic fluids are pivotal in various applications, affecting performance, efficiency, and safety. Understanding the different types of hydraulic fluids can facilitate better decision-making in selecting the right ones for specific tasks. The top five hydraulic fluid types include mineral oils, water-based fluids, biodegradable fluids, phosphate esters, and oils with special additives. According to a report by the International Fluid Power Society, choosing the appropriate fluid can improve operational efficiency by up to 25%, making it crucial for any hydraulic system.

Hydraulic fluids are pivotal in various applications, affecting performance, efficiency, and safety. Understanding the different types of hydraulic fluids can facilitate better decision-making in selecting the right ones for specific tasks. The top five hydraulic fluid types include mineral oils, water-based fluids, biodegradable fluids, phosphate esters, and oils with special additives. According to a report by the International Fluid Power Society, choosing the appropriate fluid can improve operational efficiency by up to 25%, making it crucial for any hydraulic system.

Tips: When selecting hydraulic fluid, consider the application temperature range, potential environmental impacts, and compatibility with system materials. For example, biodegradable fluids can significantly reduce environmental damage in case of leaks, making them ideal for outdoor applications.

The choice of fluid also influences the overall maintenance and longevity of hydraulic systems. Water-based fluids, while less flammable, may require careful handling to prevent corrosion. In contrast, phosphate esters, often used in aerospace applications due to their fire-resistant properties, can enhance performance under extreme conditions. By understanding these fluid options, users can optimize their hydraulic systems effectively, leading to improved performance and reduced downtime.

Essential Hydraulic Components: A Breakdown of Must-Have Products for Efficiency

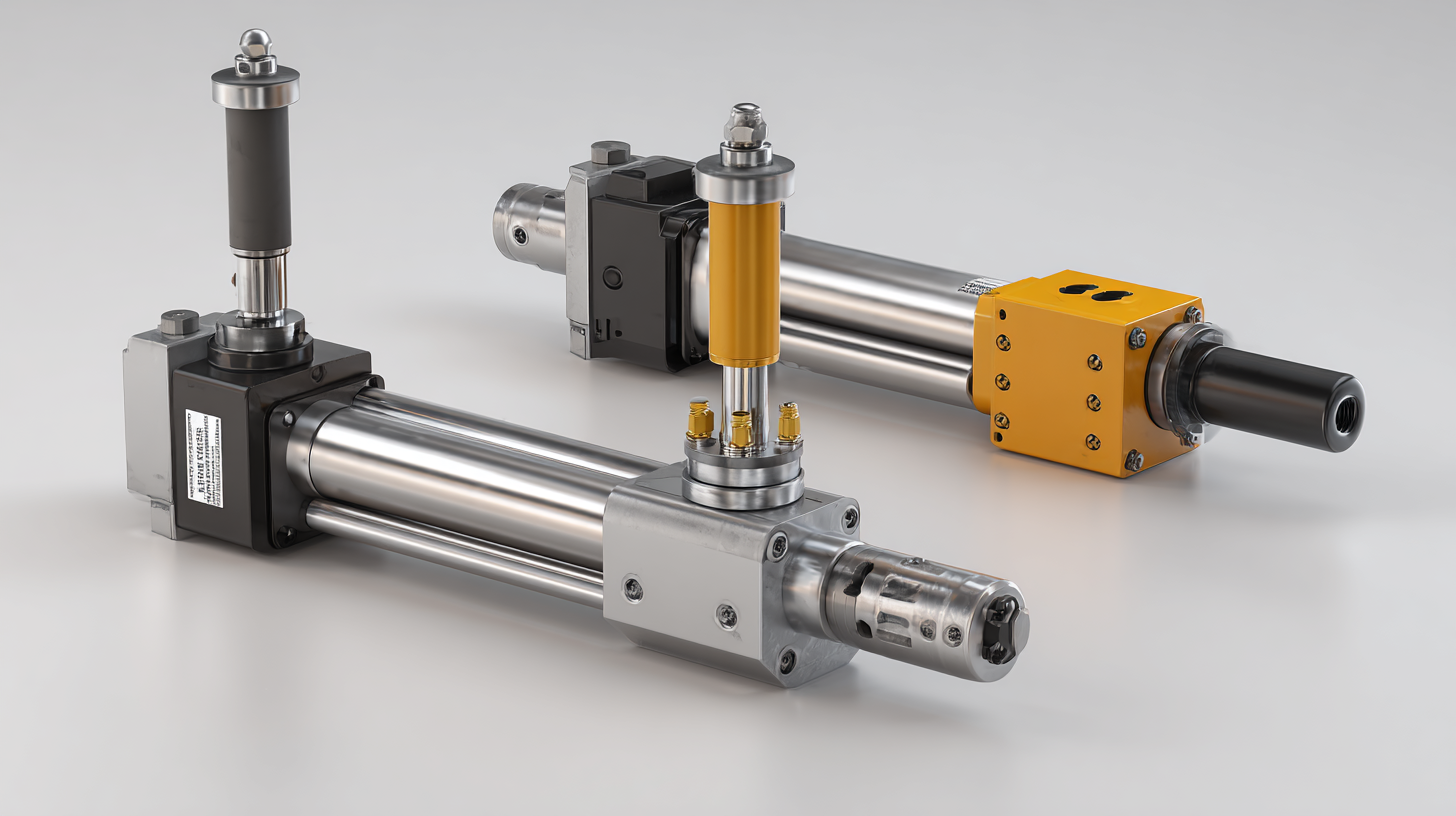

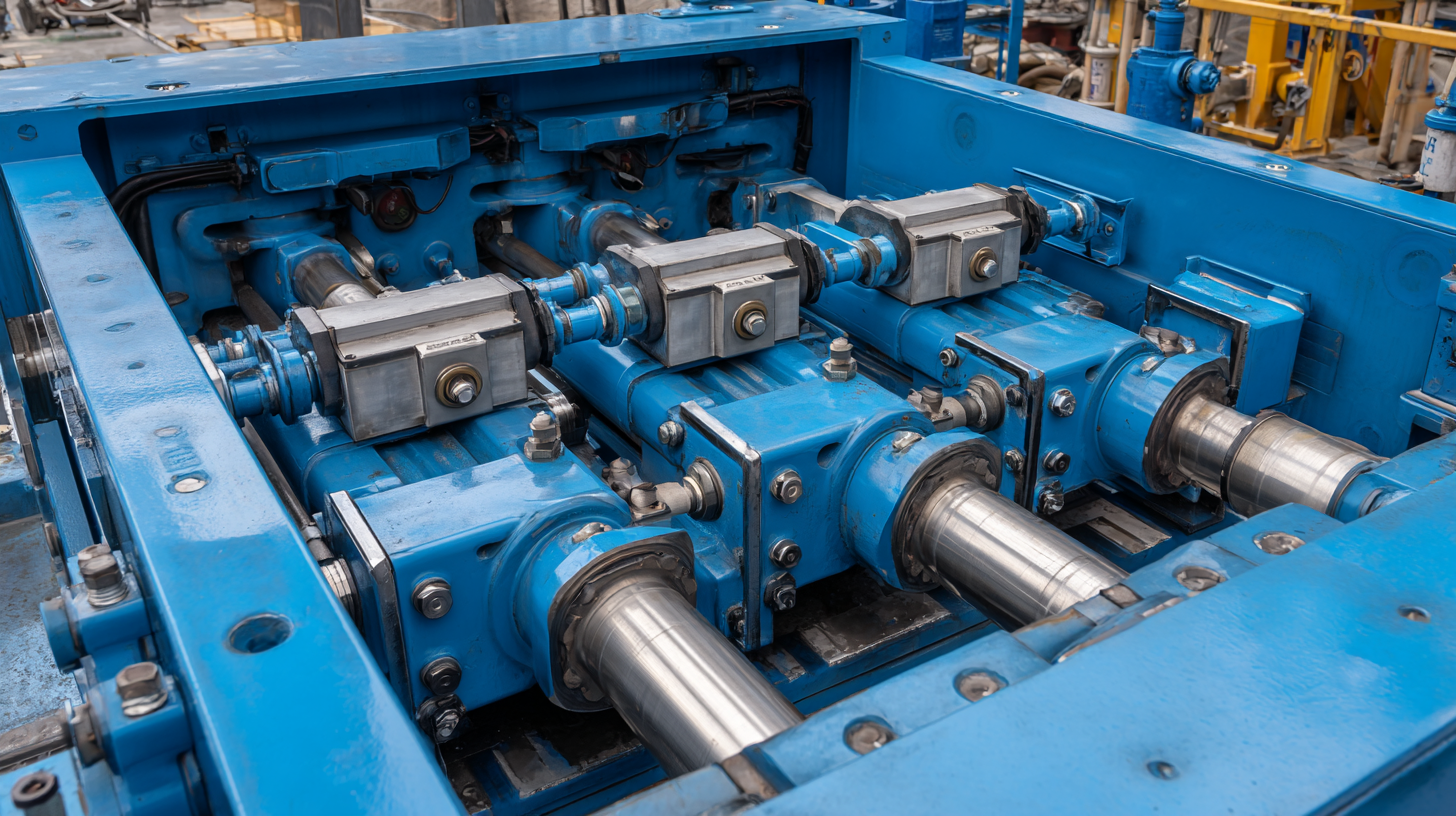

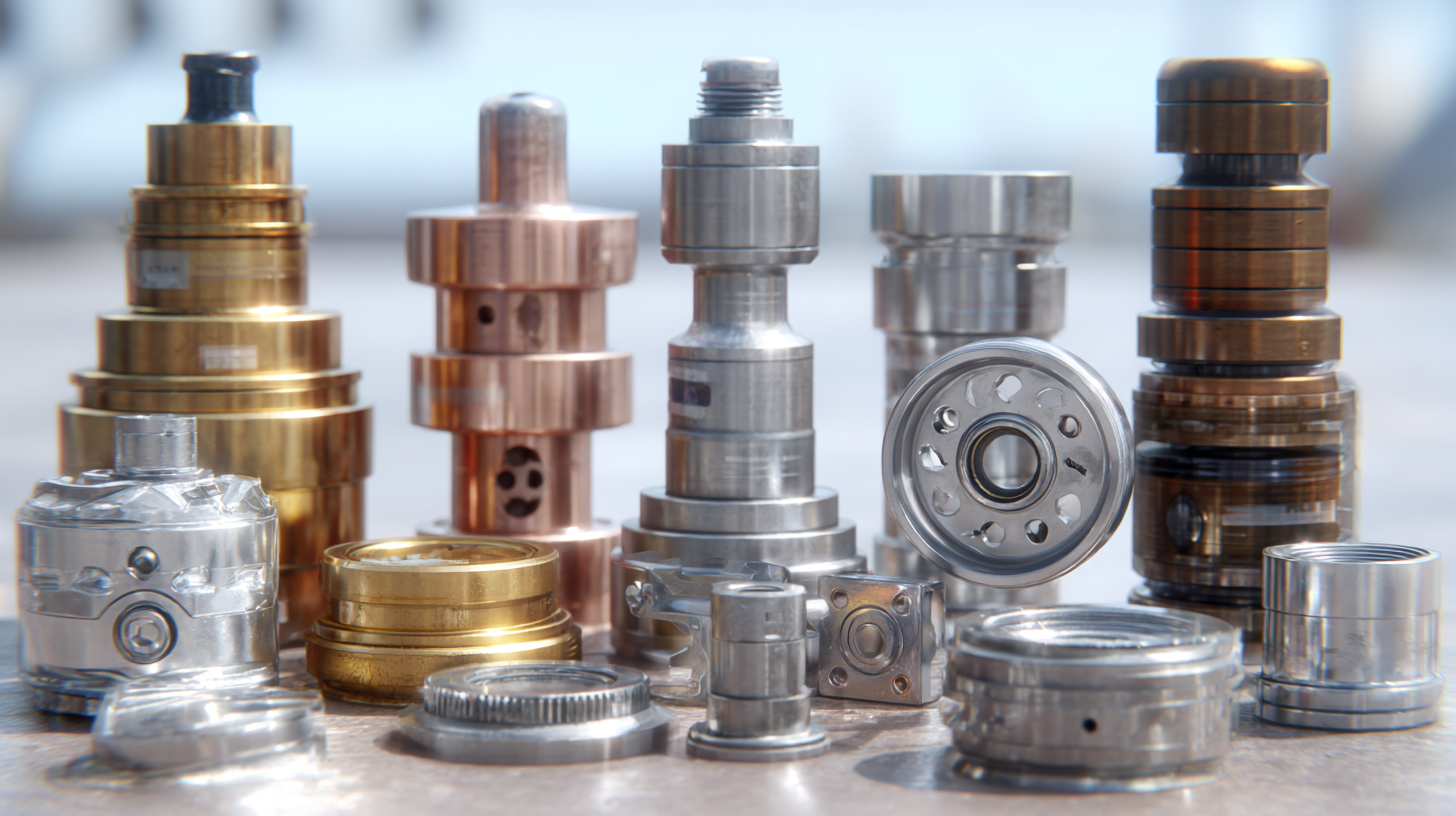

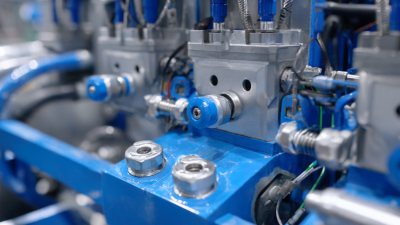

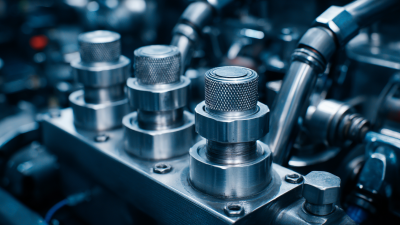

Understanding essential hydraulic components is crucial for optimizing efficiency in various applications. Key products include hydraulic pumps, which are vital for converting mechanical energy into hydraulic energy, pushing fluid through the system. Without a reliable pump, the functionality of the entire hydraulic circuit can be compromised. Another indispensable component is the hydraulic cylinder, which transforms hydraulic energy back into mechanical energy, providing the linear force needed for tasks such as lifting or moving heavy objects.

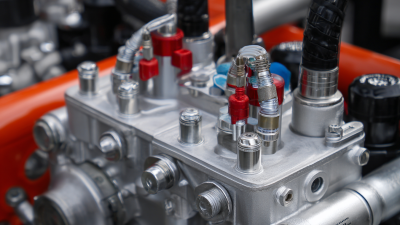

Hydraulic fittings and hoses are also critical components that ensure the safe and efficient transfer of hydraulic fluid throughout a system. High-quality hoses can withstand pressure fluctuations and temperature changes, preventing leaks and system failures. Additionally, hydraulic valves play a significant role in controlling flow and pressure, allowing operators to manage the system's functions with precision. By focusing on these essential hydraulic components, users can enhance the performance and longevity of their hydraulic systems, making their everyday applications more efficient and reliable.

Best Practices for Maintaining Hydraulics Systems for Optimal Longevity

Maintaining hydraulic systems is crucial for ensuring their longevity and efficiency. According to the International Fluid Power Society, proper maintenance can increase the lifespan of hydraulic components by up to 50%. Regular inspections and routine maintenance practices help in identifying potential issues before they escalate into costly repairs. Components such as filters, seals, and hoses require periodic checks, as even minor leaks can lead to significant performance degradation. A simple preventative approach could include weekly inspections to ensure systems are operating within optimal pressure ranges.

In addition to regular inspections, maintaining fluid quality is essential. The Hydraulic Institute reports that approximately 70% of hydraulic system failures are attributed to fluid contamination. Implementing a comprehensive fluid management program that includes regular fluid analysis can be a game changer. By using advanced filtration systems and monitoring fluid condition, operators can minimize the risk of premature wear and tear on critical components. Such best practices not only extend the lifespan of the hydraulic systems but can also improve their overall efficiency, leading to significant cost savings in operations.

Essential Guide to Understanding Hydraulics Products for Everyday Applications

| Hydraulic Component | Common Applications | Maintenance Best Practices | Expected Lifespan (Years) |

|---|---|---|---|

| Hydraulic Pump | Construction Equipment, Manufacturing | Regular fluid checks, Replace filters, Avoid overload | 10-15 |

| Hydraulic Cylinder | Material Handling, Agriculture | Inspect seals, Keep clean, Proper storage | 15-20 |

| Hydraulic Hose | Automotive, Industrial Machines | Avoid extreme bends, Regular inspection, Replace worn hoses | 5-10 |

| Hydraulic Fluid | All hydraulic systems | Use correct fluid type, Monitor fluid levels, Change fluid regularly | Varies by application |

| Hydraulic Filter | Mobile Equipment, Industrial Systems | Change filters regularly, Ensure proper installation, Monitor pressure drops | 5-7 |

Innovations in Hydraulic Technology: How They Enhance Everyday Applications

Innovations in hydraulic technology have significantly enhanced everyday applications across various industries, from automotive to manufacturing. For instance, according to a report by MarketsandMarkets, the hydraulic equipment market is projected to reach $59.5 billion by 2025, driven by advancements in automation and the increasing demand for efficient machinery. This surge reflects the need for more powerful and reliable hydraulic systems that can improve operational efficiency and reduce energy consumption.

One of the most notable innovations is the development of compact hydraulic systems, which offer higher performance in a smaller footprint. These systems utilize advanced materials and smart technology, allowing for real-time monitoring and adaptive control. A study by the National Hydraulic Institute found that implementing modern hydraulic solutions can lead to a 20-30% increase in energy efficiency, making them ideal for applications like construction machinery and automated production lines. Furthermore, the integration of IoT (Internet of Things) in hydraulic systems is revolutionizing maintenance practices, reducing downtime by up to 40% through predictive analytics and remote monitoring. As these technologies evolve, they continue to reshape our interaction with hydraulic products in everyday applications.

Related Posts

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

What Are the Key Components of Hydraulics Products and Their Applications

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

skip to Main Content

skip to Main Content