Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

In today's fast-paced industrial landscape, the efficiency and reliability of processes hinge significantly on the performance of control valves. According to a recent report by MarketsandMarkets, the global control valve market is projected to reach USD 10.1 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth underscores the increasing reliance on advanced control valves to optimize operational efficiency across various sectors, including oil and gas, water and wastewater management, and chemical processing.

Industry expert Dr. Emily Tran, a renowned authority in valve technologies, emphasizes the critical role that innovation plays in this sector. She stated, “The future of control valves is not just about functionality but about integrating smart technologies that enhance performance and adaptability in ever-changing industrial environments.” As we delve into the top innovations and trends driving the evolution of control valves, it becomes essential to acknowledge how these advancements are paving the way for enhanced automation, improved energy efficiency, and greater sustainability in industrial practices.

As we explore these developments, we will highlight key trends such as the rise of smart valves, predictive maintenance solutions, and the increasing adoption of eco-friendly materials. These advancements not only promise to improve the performance of control valves but also align with the broader industry goals of reducing costs and minimizing environmental impact.

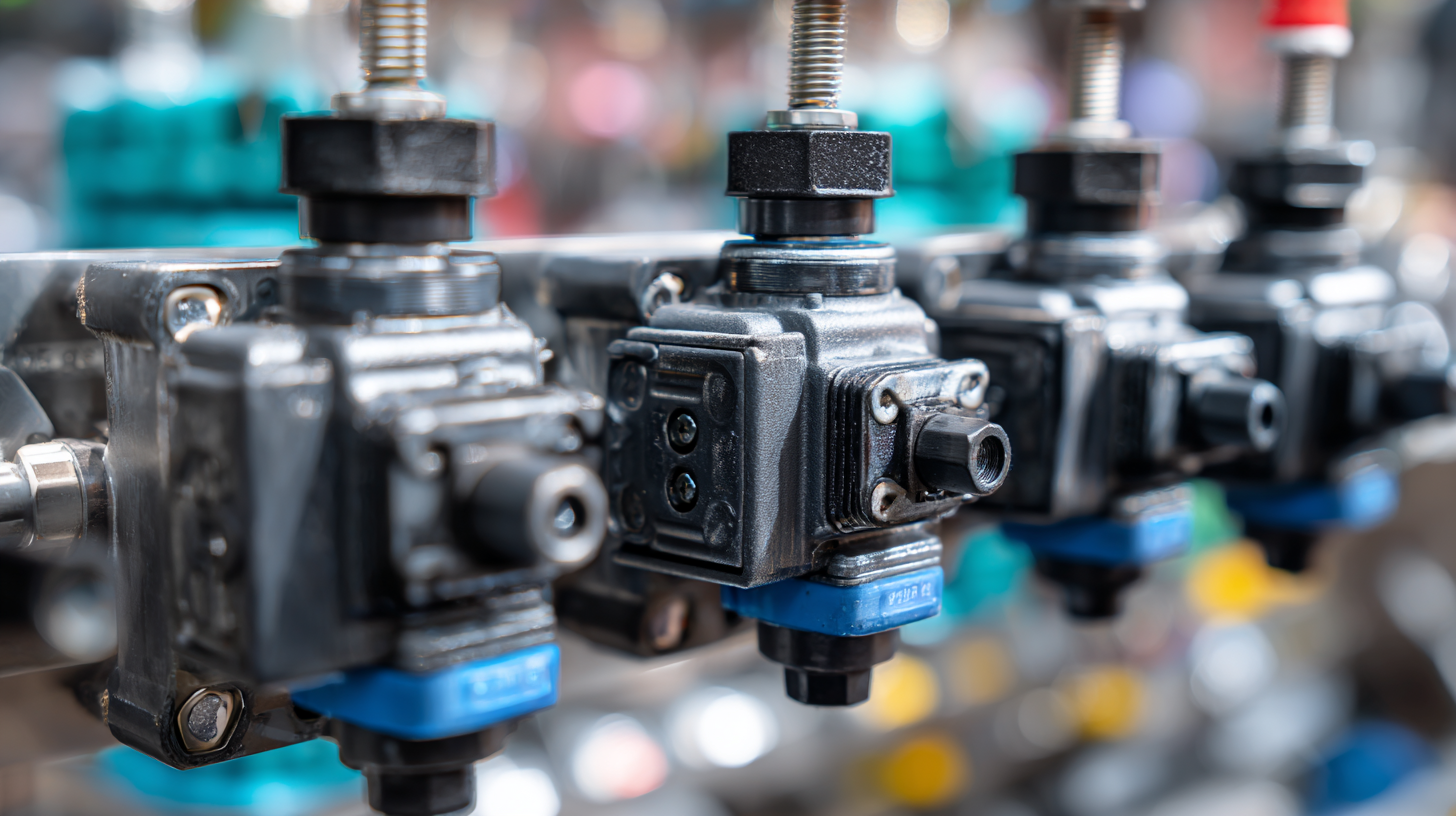

Innovative Materials Enhancing Durability and Performance of Control Valves in Industry

Innovative materials are playing a pivotal role in enhancing the durability and performance of control valves across various industries. The pharmaceutical sector, for instance, is projected to witness significant growth with the diaphragm valve market expected to increase from $123.3 million in 2024 to $284.6 million by 2032, reflecting a compound annual growth rate (CAGR) of 11.02%. This surge emphasizes the demand for advanced materials that can withstand the rigorous environments typically encountered in pharmaceutical processes.

Moreover, leading companies are focusing on the development of "three-resistant" materials—resistant to corrosion, abrasion, and high temperatures. Such innovations not only improve the lifespan of control valves but also ensure operational efficiency and reliability. The control valve market as a whole is showing promising growth, with a detailed analysis indicating that its expansion is driven by advancements in material science, specifically tailored to meet the increasing demands for high-end manufacturing capabilities. This trend is critical as industries strive for better performance and sustainability in their production processes.

Smart Control Valve Technology: The Role of IoT in Real-Time Monitoring and Efficiency

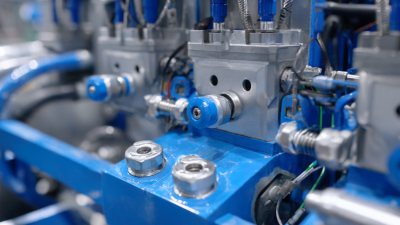

The integration of smart control valve technology, particularly through the Internet of Things (IoT), is revolutionizing industrial processes by enabling real-time monitoring and enhancing operational efficiency. The use of connected valves facilitates precise control over gas systems, contributing to improved safety and quality within manufacturing environments. As industries evolve, controlling environmental impacts while maintaining productivity has become paramount, and smart valves play a critical role in achieving this balance.

In sectors such as offshore oil extraction and agriculture, the implementation of IoT has led to significant advancements. For example, smart oil platforms now leverage automation to enhance both safety and efficiency, particularly in challenging deep-water settings. Similarly, intelligent irrigation systems help reduce water consumption and waste, showcasing how technological innovations can drive sustainability. The growing market for smart control valves and associated technologies indicates a shift towards more intelligent and responsive industrial ecosystems, aligning with the broader trends of Industry 4.0.

Predictive Maintenance: Minimizing Downtime with Advanced Analytics in Control Valve Operations

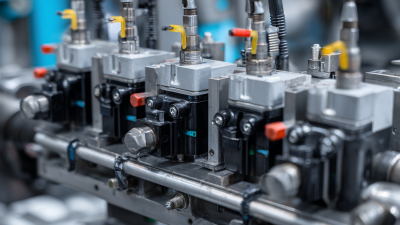

Predictive maintenance is revolutionizing control valve operations by leveraging advanced analytics to minimize downtime and enhance efficiency. In the past, traditional maintenance approaches often led to unforeseen failures and unplanned shutdowns, which could severely impact productivity and operational costs. By implementing predictive maintenance strategies, industries can analyze historical performance data and real-time operating conditions to forecast potential issues before they escalate into critical failures.

The adoption of machine learning algorithms and Internet of Things (IoT) technologies plays a pivotal role in this transformation. Sensors installed on control valves collect a myriad of data points, allowing for continuous monitoring of their health and performance. This data is then processed to identify patterns that indicate wear and tear or inefficiencies. Consequently, maintenance teams can schedule interventions proactively, addressing issues during planned downtimes rather than during emergency shutdowns. This strategic approach not only prolongs the life of control valves but also enhances overall operational efficiency, leading to significant cost savings and improved safety in industrial environments.

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

| Dimension | Description | Impact on Efficiency | Trending Technology |

|---|---|---|---|

| Predictive Maintenance | Utilizing advanced analytics to forecast failures and schedule maintenance | Reduces unplanned downtime and extends equipment lifespan | IoT Sensors, Machine Learning |

| Smart Control Valves | Valves equipped with sensors and communication devices | Enhances automation, real-time monitoring, and data collection | AI Integration, Cloud Computing |

| Energy Efficiency | Innovations aimed at reducing energy consumption in valve operations | Lowers operational costs and minimizes environmental impact | Variable Frequency Drives, Energy Harvesting |

| Real-time Data Analytics | Analyzing data from valve operations in real-time | Improves decision making and operational efficiency | Big Data, Edge Computing |

| Digital Twins | Virtual representations of control valve systems for simulation and analysis | Enhances predictive maintenance and system optimization | Simulation Software, IoT Integration |

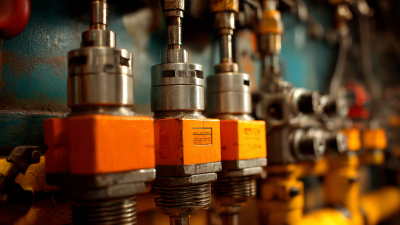

Automation and Robotics: Transforming Control Valve Management and Process Efficiency

The evolution of automation and robotics in control valve management is reshaping how industries enhance operational efficiency. According to a report by the International Society of Automation (ISA), the implementation of automated control systems can lead to a 30-50% increase in process efficiency. This transformative technology not only optimizes performance but also minimizes human error, ensuring that processes run smoothly and effectively.

Advanced robotics can facilitate predictive maintenance, which is projected to reduce downtime by up to 25%, significantly impacting productivity levels across various sectors.

Advanced robotics can facilitate predictive maintenance, which is projected to reduce downtime by up to 25%, significantly impacting productivity levels across various sectors.

Tips: When considering automation in your operations, prioritize training for your staff to adapt to new technologies. Additionally, regularly assess the performance of automated systems to ensure they align with efficiency goals.

Moreover, the integration of Internet of Things (IoT) capabilities in control valves is opening new dimensions for data analysis and remote monitoring. A Deloitte report highlighted that industries adopting smart valve technologies see a marked improvement in real-time decision-making, leading to a sharper competitive edge. As companies increasingly leverage big data and machine learning algorithms, the ability to analyze fluctuations and trends is becoming an invaluable asset for optimizing valve management and enhancing overall process performance.

Tips: Stay informed about advancements in IoT technologies and consider pilot programs to test their effectiveness before full implementation. Developing a strategy for data utilization can further drive efficiency improvements.

Sustainability Trends: How Eco-friendly Control Valve Solutions are Shaping the Future of Industry

The industrial sector is increasingly focusing on sustainability, particularly in the realm of control valves, which are vital for managing fluid dynamics across various applications. Innovations such as eco-friendly materials and advanced designs are leading to more efficient and environmentally conscious solutions. With the rise of AI-powered operational intelligence, industries can optimize valve performance while minimizing waste and emissions. This shift towards sustainable control valve solutions is not only beneficial for the environment but also aligns with the growing regulatory and consumer demands for more responsible manufacturing practices.

Tips for achieving sustainability in control valve applications include investing in automated systems that ensure precision in fluid management, integrating water recycling technologies, and considering decentralized infrastructure to reduce dependency on traditional resources. Implementing these strategies can significantly enhance operational efficiency. Additionally, incorporating smart technologies into water treatment processes can drive further innovations, allowing industries to proactively manage their consumption and environmental impact. The future of control valves lies in embracing these sustainability trends, which are reshaping the landscape of industrial operations.

Innovations in Control Valve Technologies

This chart illustrates the percentage of market interest in various innovative control valve technologies that are shaping the industry's future. Smart valves lead the interest, followed by eco-friendly materials and energy-efficient designs, showing a strong trend towards sustainable and efficient solutions.

Related Posts

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

How to Optimize Your System with Automated Valves for Maximum Efficiency

-

What is the Future of Automated Valves in Modern Industries

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

skip to Main Content

skip to Main Content