What is Flow Control Valves and How Do They Work?

Flow control valves play a critical role in various industrial applications. These devices regulate fluid flow, ensuring systems operate efficiently. As John Smith, a renowned expert in the fluid dynamics industry, states, "Understanding flow control valves is essential for optimizing system performance."

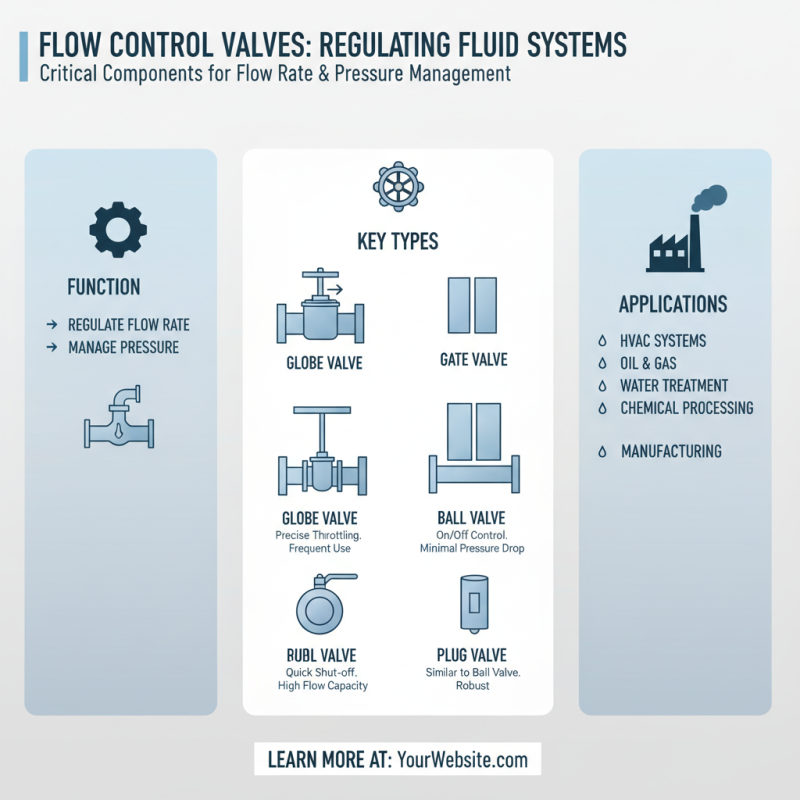

Flow control valves manage pressure and flow rates in piping systems. They can prevent damage from excessive pressure. Various types exist, each serving specific functions. For example, needle valves provide precise flow adjustments, while globe valves are excellent for throttling applications. The choice of valve significantly impacts system efficiency and longevity.

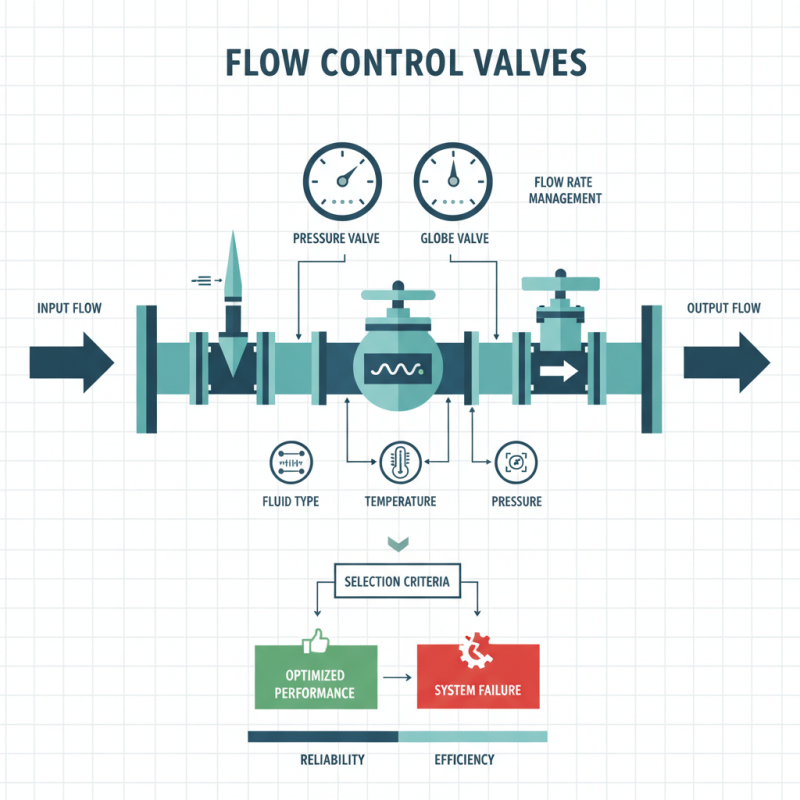

However, selecting the right flow control valve can be challenging. Engineers must consider factors like fluid type, temperature, and pressure. A mismatch can lead to inefficient operation and increased costs. It’s crucial to evaluate both performance and reliability. A well-chosen valve can make a difference, but poor choices can result in system failures. Maintaining awareness of these issues is key to successful applications.

What is a Flow Control Valve?

A flow control valve regulates the flow of liquids or gases in systems. It helps maintain consistent pressure and flow rates. This control is essential in various applications, from manufacturing to water management.

Proper flow control is vital. According to a recent industry report, poorly adjusted flow rates can lead to energy losses of up to 30%. This inefficiency is not just a cost issue; it can reduce system lifespan. Manufacturers often overlook regular maintenance, which can exacerbate these issues. Simple checks can make a significant difference.

Flow control valves come in different types, such as needle valves and gate valves. Each type serves unique purposes and settings. Understanding your specific needs can enhance system performance. However, many users continue to apply a one-size-fits-all mindset. This approach may lead to suboptimal solutions. Recognizing the distinct requirements of each application is crucial for efficiency and safety.

Types of Flow Control Valves and Their Applications

Flow control valves are critical components in fluid systems. They regulate the flow rate and pressure. Various types of flow control valves are available, each serving different applications.

One common type is the needle valve. This valve allows precise control over flow rates. It's often used in laboratories. The design features a slender, tapered point. This design can limit flow dramatically. However, it may require frequent adjustments for accurate results.

Another popular type is the orifice valve. This simple design can handle high pressure. It creates a specific flow path, ensuring even distribution. Orifice valves are widely used in industrial processes. They can be less flexible in controlling changes in flow.

**Tips:** When choosing a flow control valve, consider the application and fluid type. Not all valves are suitable for every environment. Regular maintenance is crucial for optimal performance. Keep in mind that even small leaks can lead to significant issues down the line.

One frequently overlooked type is the proportional valve. It adjusts flow based on control signals. This feature makes it ideal for automation. However, they can be costly and complex to install. Understanding your system's needs is essential before investing.

How Flow Control Valves Operate: Mechanisms Explained

Flow control valves play a crucial role in managing fluid flow in various systems. They regulate the rate of flow, ensuring that operations run smoothly and efficiently. According to a 2022 industry report, the global market for flow control valves is projected to reach $10 billion by 2026. This growth highlights the increasing importance of precise flow management in sectors like oil and gas, water treatment, and manufacturing.

There are different mechanisms used in flow control valves. Some operate on a manual basis, while others are automatic or electronically controlled. Classic designs include gate valves and globe valves, which adjust flow by changing the valve's position. In contrast, more advanced designs, such as proportional valves, can fine-tune flow rates for greater accuracy. However, the complexity of these systems can lead to challenges, such as malfunctioning sensors or leaks. Data from a recent survey indicated that 30% of companies face issues with valve reliability, impacting overall performance.

One interesting aspect is the response time of these valves. Faster response times can enhance system efficiency but may lead to stability issues. It is essential to balance speed with reliability. An inconsistent flow can cause equipment wear and increase maintenance costs. Engineers must continuously evaluate designs and materials to reduce failures. Adapting to various operational conditions requires both innovative thinking and ongoing research.

Importance of Flow Control Valves in Fluid Dynamics

Flow control valves play a crucial role in fluid dynamics. They regulate the flow of liquids and gases in various systems. These valves help maintain a desired flow rate, ensuring optimal performance. Without them, systems could face pressure surges or inadequate flow. This can lead to equipment damage or inefficient operation.

In industries like manufacturing and HVAC, flow control valves are essential. They allow precise control over fluid movement. For example, in a cooling system, they prevent overheating by maintaining a consistent coolant flow. Despite their importance, some systems still lack proper valve implementation. This oversight can lead to costly downtime.

Moreover, understanding the dynamics at play is vital. Flow rates can change due to various factors, such as temperature or pressure fluctuations. Designers must consider these elements carefully. There should always be room for improvement in valve design and application. Striving for better solutions can enhance efficiency in fluid systems significantly.

Maintenance and Troubleshooting for Flow Control Valves

Flow control valves are essential in various industrial applications. They regulate fluid flow, ensuring efficiency and safety. However, they require regular maintenance to function optimally. One study indicated that improper maintenance can lead to a 10% drop in performance over time. Regular checks can prevent these issues, saving costs in the long run.

Troubleshooting flow control valves involves simple methods. Inspect the valve for leaks and unusual noises. Such signs can indicate wear or damage. A survey revealed that 25% of operators overlook noisy valves, risking system failure. Additionally, maintaining correct pressure and temperature levels is vital. Deviations from standard operating conditions can lead to valve malfunction.

Routine maintenance should include cleaning and lubricating components. Neglecting these tasks can result in sticky valves, hindering their response. Another report highlighted that up to 15% of failures were due to insufficient lubrication. Addressing these maintenance needs promptly can improve reliability and extend the valve's lifespan. Regular training for staff on these protocols also enhances overall system integrity.

Related Posts

-

Innovative Flow Control Valves on Display at the 138th Canton Fair in 2025

-

10 Essential Flow Control Valves Every Industry Should Consider

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

How to Choose the Right Pump Valves for Your Industrial Needs

-

Understanding the Power of Pneumatic and Hydraulic Systems in Modern Industry with Over 300 Billion USD Revenue

skip to Main Content

skip to Main Content