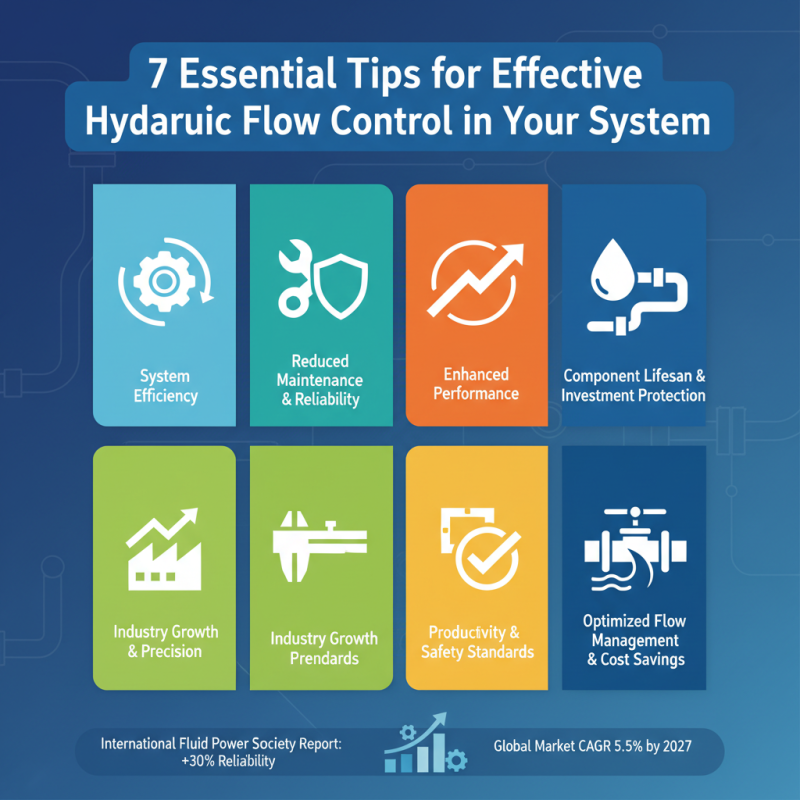

7 Essential Tips for Effective Hydraulic Flow Control in Your System

Hydraulic flow control is a crucial aspect of hydraulic systems that significantly impacts their efficiency and performance. According to a report by the International Fluid Power Society, proper hydraulic flow management can enhance system reliability by up to 30%, leading to reduced maintenance costs and improved operational efficiency. As industries increasingly rely on advanced hydraulic technologies, the need for effective hydraulic flow control becomes even more pressing. Efficient flow management not only ensures optimal performance but also prolongs the lifespan of hydraulic components, thus safeguarding investments in equipment and infrastructure.

Moreover, the global hydraulic systems market is projected to grow at a CAGR of 5.5% through 2027, reflecting the rising demand for precision engineering in various sectors, including manufacturing, construction, and automotive. Effective hydraulic flow control techniques are key to meeting the required standards of productivity and safety within these industries. This article presents seven essential tips for optimizing hydraulic flow control in your system, aimed at maximizing efficiency while minimizing unnecessary wear on components. By implementing these strategies, users can harness the full potential of their hydraulic systems, leading to enhanced performance and significant cost savings.

Understanding Hydraulic Flow Control: Key Principles and Concepts

Hydraulic flow control is a fundamental aspect in the design and operation of hydraulic systems. To effectively manage the flow of hydraulic fluid, it is essential to understand several key principles, including

fluid dynamics,

pressure regulation, and the behavior of hydraulic components. These principles help in optimizing system performance, maximizing efficiency, and ensuring precise control of hydraulic devices.

One of the core concepts in hydraulic flow control is the relationship between flow rate and pressure. By manipulating these variables, operators can maintain an ideal flow condition and prevent issues such as

cavitation or

overpressure scenarios that could lead to system failure. Additionally, integrating flow control devices, like valves and regulators, allows for dynamic adjustments based on the system’s operational demands. Understanding the characteristics of these components, along with their response to varying conditions, is crucial for achieving optimal flow control in hydraulic applications.

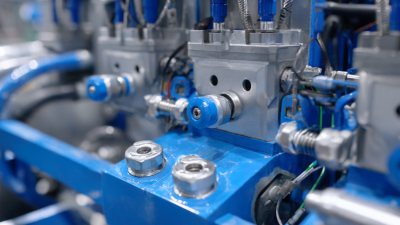

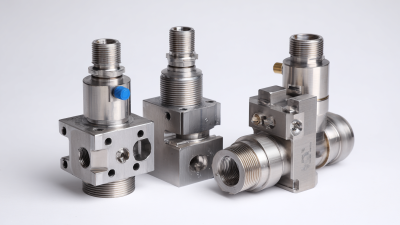

Choosing the Right Components for Optimal Hydraulic Flow Management

Choosing the right components for optimal hydraulic flow management is critical for the performance and longevity of your hydraulic system. The selection of hydraulic pumps, valves, filters, and hoses plays a vital role in ensuring efficient flow control and minimizing energy losses. When selecting a pump, it is essential to match its capacity and pressure ratings with the system's operational requirements. This alignment helps prevent premature wear and mechanical failure, ensuring that the system operates smoothly under varying load conditions.

In addition to pumps, the choice of valves significantly influences flow direction and pressure regulation within the system. Opting for high-quality, responsive valves can enhance performance by providing precise flow control. Filters are equally important as they remove contaminants that can cause clogging and damage to components. Lastly, the selection of hoses should focus on compatibility with hydraulic fluids and the ability to withstand pressure fluctuations. Ensuring that each component is tailored to the specific needs of your system will enhance efficiency and reliability, ultimately leading to better overall performance.

7 Essential Tips for Effective Hydraulic Flow Control in Your System

Effective Techniques for Measuring and Monitoring Hydraulic Flow

Effective hydraulic flow measurement and monitoring are crucial for maintaining the efficiency and reliability of hydraulic systems. To start, utilizing flow meters is essential; these instruments provide real-time data on the flow rate, enabling operators to make informed decisions about system adjustments. Accurate measurements can prevent issues related to flow surges or drops, which could lead to system failures or inefficiencies. Moreover, ensuring that the flow meters are properly calibrated is vital for delivering accurate results.

In addition to flow meters, implementing advanced monitoring systems can enhance the management of hydraulic flow. These systems can include sensors that track not only flow rate but also temperature and pressure, providing a comprehensive view of system performance. By integrating this data into a centralized dashboard, operators can quickly identify anomalies and initiate corrective actions. Regularly reviewing this data helps in anticipating maintenance needs, thus minimizing unexpected downtimes and enhancing overall system longevity.

7 Essential Tips for Effective Hydraulic Flow Control in Your System - Effective Techniques for Measuring and Monitoring Hydraulic Flow

| Tip Number | Tip Description | Measurement Technique | Monitoring Frequency | Importance Level |

|---|---|---|---|---|

| 1 | Regularly Inspect Connections | Visual Inspection | Weekly | High |

| 2 | Check Fluid Levels | Dipstick Measurement | Daily | Critical |

| 3 | Use Flow Meters | Digital Flow Meter | Continuous | High |

| 4 | Monitor Pressure Levels | Pressure Gauge | Hourly | High |

| 5 | Implement Data Logging | Automated Data Logger | Real-time | Medium |

| 6 | Inspect Filters Regularly | Filter Inspection | Monthly | Medium |

| 7 | Use Quality Components | Material Quality Check | N/A | Critical |

Common Challenges in Hydraulic Flow Control and How to Overcome Them

Hydraulic flow control systems are essential for the efficient operation of various industrial applications, yet they often face significant challenges. One of the most common issues is pressure fluctuations, which can lead to instability in the hydraulic system. These fluctuations may result from abrupt changes in flow rate or leaks in the system. To mitigate this, it is crucial to incorporate pressure relief valves and accumulators that can buffer sudden changes, maintaining a steady flow and protecting the system from potential damage.

Another prevalent challenge in hydraulic flow control is the risk of cavitation, which occurs when the pressure in a hydraulic fluid drops below its vapor pressure, causing vapor bubbles to form. This can lead to reduced efficiency and damage to components. To overcome cavitation, it is vital to maintain appropriate fluid levels and avoid restrictive fittings or valves that could create pressure drops. Additionally, selecting fluids with optimal viscosity and ensuring proper system design can significantly enhance performance and reliability, ensuring smoother operation over time. By proactively addressing these challenges, operators can enhance the lifespan and efficiency of their hydraulic systems.

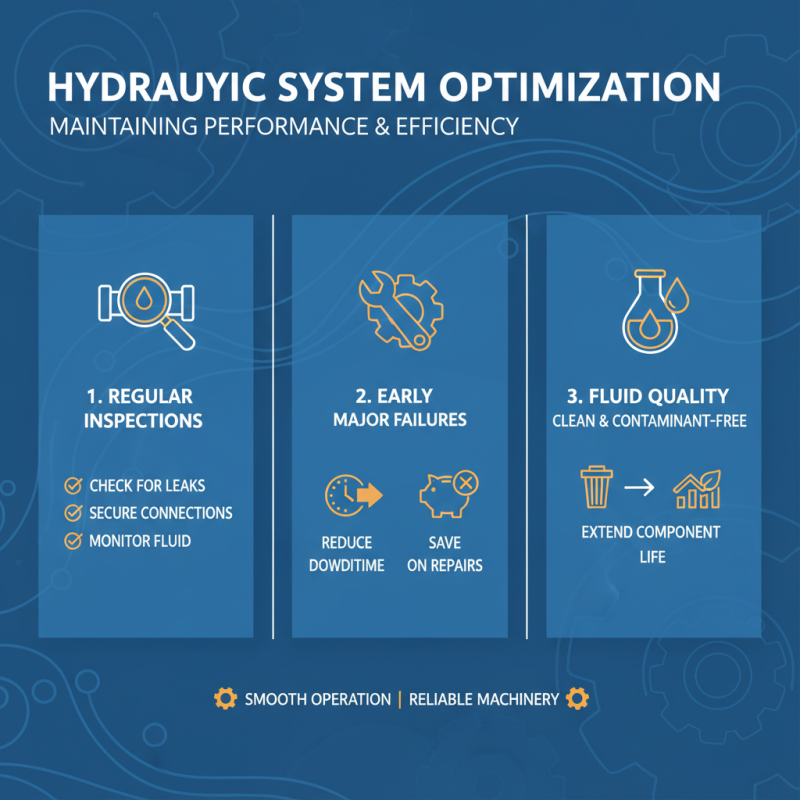

Best Practices for Maintaining Hydraulic System Performance and Efficiency

Maintaining hydraulic system performance and efficiency is pivotal for the smooth operation of any machinery reliant on hydraulic flow control. One of the best practices is to conduct regular inspections and maintenance. This includes checking for leaks, ensuring that all connections are secure, and monitoring fluid levels and quality. By identifying issues early, you can prevent major failures that could lead to costly downtime and repairs.

Another vital aspect is properly selecting and maintaining hydraulic fluids. The right fluid not only supports effective flow control but also enhances lubrication and cooling within the system. Regularly changing the hydraulic fluid based on operational conditions ensures that the system remains free from contaminants that could hinder performance. Additionally, keeping filters clean and replacing them as needed helps maintain the quality of the hydraulic fluid, thus extending the life of your hydraulic system and improving its efficiency.

Related Posts

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

10 Essential Tips for Mastering Hydraulic Flow Control Techniques

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

skip to Main Content

skip to Main Content