Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

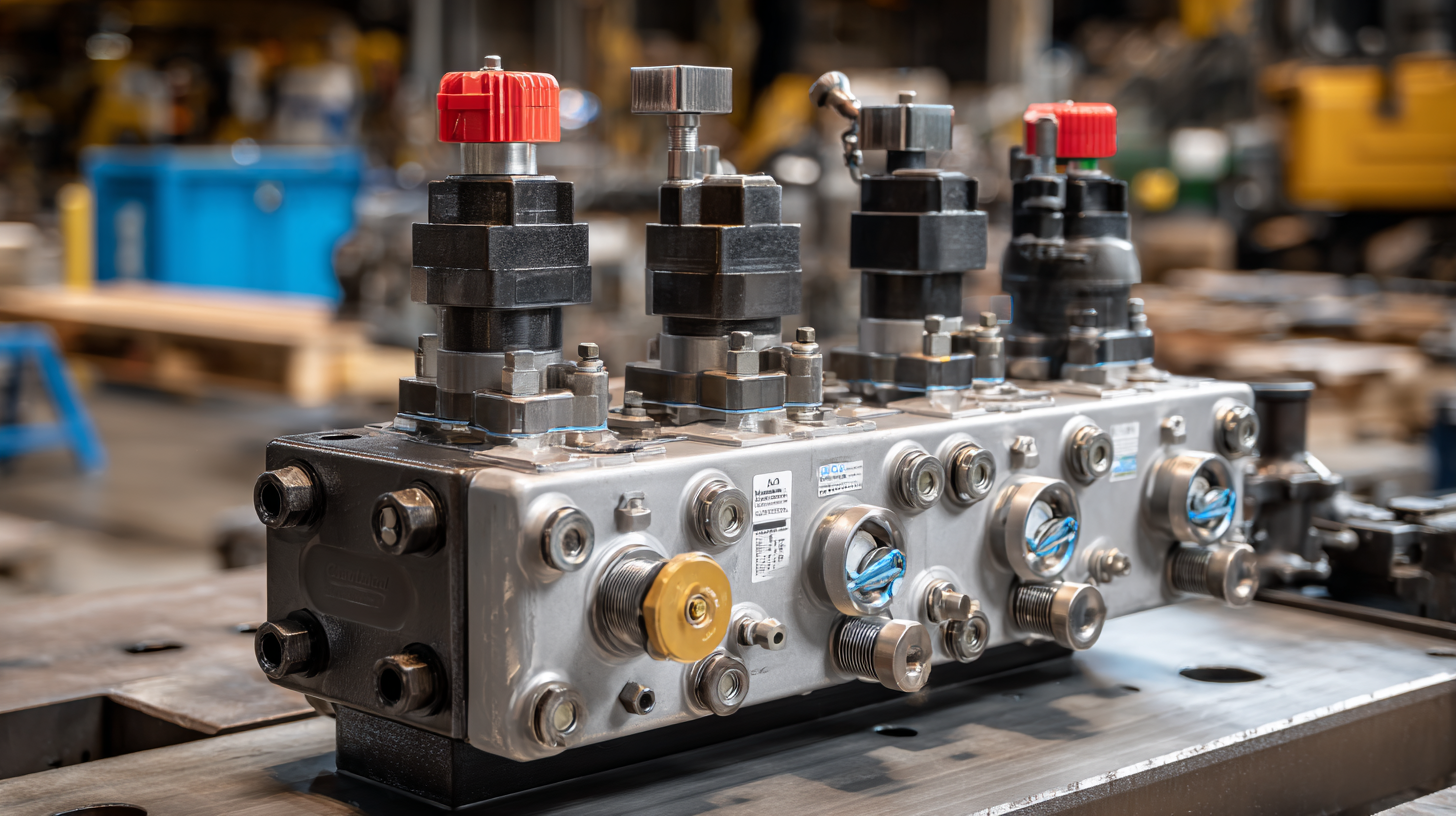

In the rapidly evolving landscape of modern industry, the significance of efficient and reliable hydraulic systems cannot be overstated. At the forefront of this technological advancement are continental hydraulic valves, which play a crucial role in enhancing the performance and functionality of various industrial applications.

These valves are integral components that regulate the flow and pressure of hydraulic fluids, ensuring optimal operation of machinery across sectors such as manufacturing, construction, and agriculture. As industries increasingly adopt automation and advanced control systems, the demand for sophisticated hydraulic solutions has surged, highlighting the essential role of continental hydraulic valves in driving operational efficiency and precision.

This article delves into the best practices and innovations surrounding these valves, emphasizing their impact on productivity and the future of industrial processes.

Understanding the Basics of Continental Hydraulic Valves and Their Applications

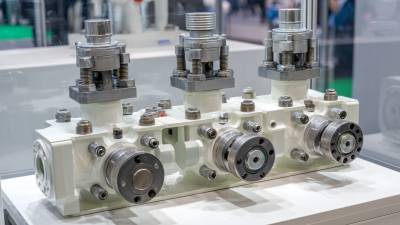

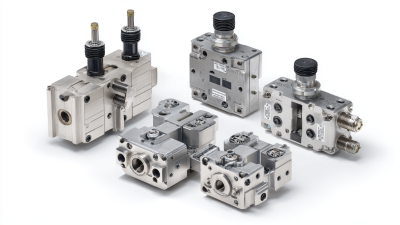

Continental hydraulic valves play a crucial role in various modern industrial applications, serving as key components in hydraulic systems that facilitate power transmission and control. These valves manage the flow and pressure of hydraulic fluids, ensuring efficient operation of machinery used in industries such as manufacturing, construction, and automotive. According to a report by MarketsandMarkets, the global hydraulic valve market is projected to reach USD 4.89 billion by 2025, reflecting a significant compound annual growth rate (CAGR) of 4.5% from 2020. This growth underscores the increasing reliance on hydraulic systems within industrial settings.

The application of Continental hydraulic valves extends beyond mere fluid control; they are integral in optimizing performance and enhancing safety in hydraulic circuits. For instance, directional control valves enable the precise movement of actuators, while pressure relief valves protect systems from overpressure situations. Industry standards set by organizations such as ISO and SAE ensure the reliability and quality of these valves, which are vital for maintaining operational efficiency. The integration of advanced technologies, such as IoT-enabled hydraulic systems, is further propelling the demand for innovative valve solutions, as reported by Research and Markets, predicting significant advancements in hydraulic technology that will reshape operational methodologies across sectors.

Key Features and Benefits of Continental Hydraulic Valves in Industrial Settings

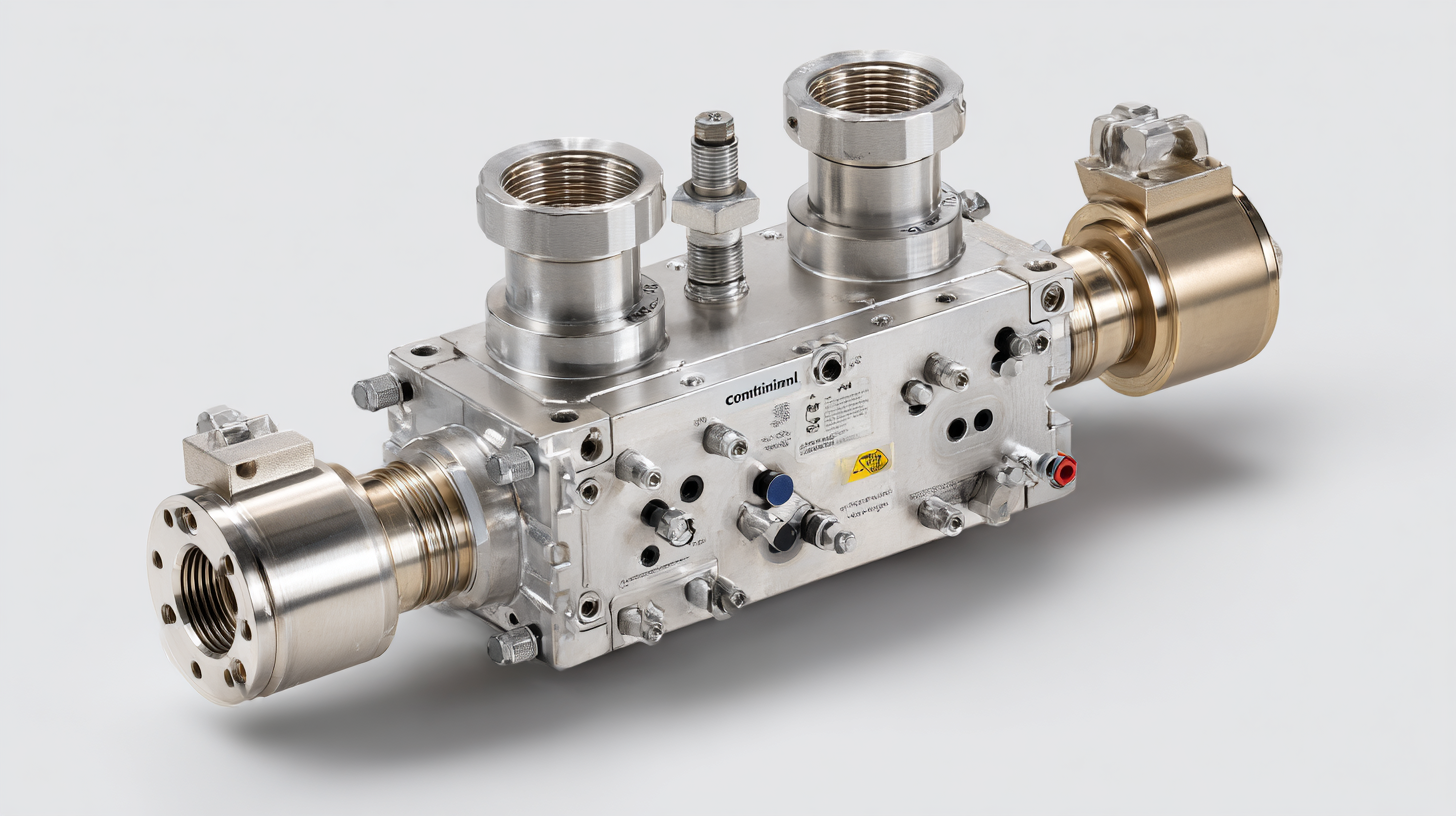

Continental hydraulic valves play a crucial role in modern industrial applications, offering features that enhance the efficiency and safety of hydraulic systems. One of their key benefits is the precision control they provide in fluid power applications, allowing for smooth operation and responsive functionality. This precision is vital in sectors such as manufacturing and construction, where even minor delays can lead to significant costs.

Moreover, Continental hydraulic valves are designed with durability in mind, often featuring robust materials that can withstand the rigors of heavy-duty environments. This longevity reduces maintenance requirements and minimizes downtime, which is essential for maintaining productivity in fast-paced industries.

**Tip:** When selecting hydraulic valves, consider the specific application and environment to choose valves that match the required flow rate and pressure levels.

Additionally, the versatility of these valves means they can be customized for various industrial needs. They are compatible with a range of hydraulic fluids, which allows companies to use them in different operational contexts without compromising performance.

**Tip:** Regularly inspect and service hydraulic valves to ensure optimal function and prevent wear and tear, which can extend their lifespan and provide better overall performance.

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry - Key Features and Benefits of Continental Hydraulic Valves in Industrial Settings

| Feature | Description | Benefit |

|---|---|---|

| High Precision Control | Allows for accurate flow and pressure regulation. | Improves operational efficiency and process stability. |

| Durability | Designed to withstand high-pressure environments. | Reduces maintenance costs and downtime. |

| Versatility | Can be used in a variety of hydraulic applications. | Enhances compatibility with different systems. |

| Compact Design | Space-saving configuration for industrial setups. | Facilitates integration in tighter spaces. |

| Energy Efficiency | Optimized for reduced energy consumption during operation. | Lowers operational costs and environmental impact. |

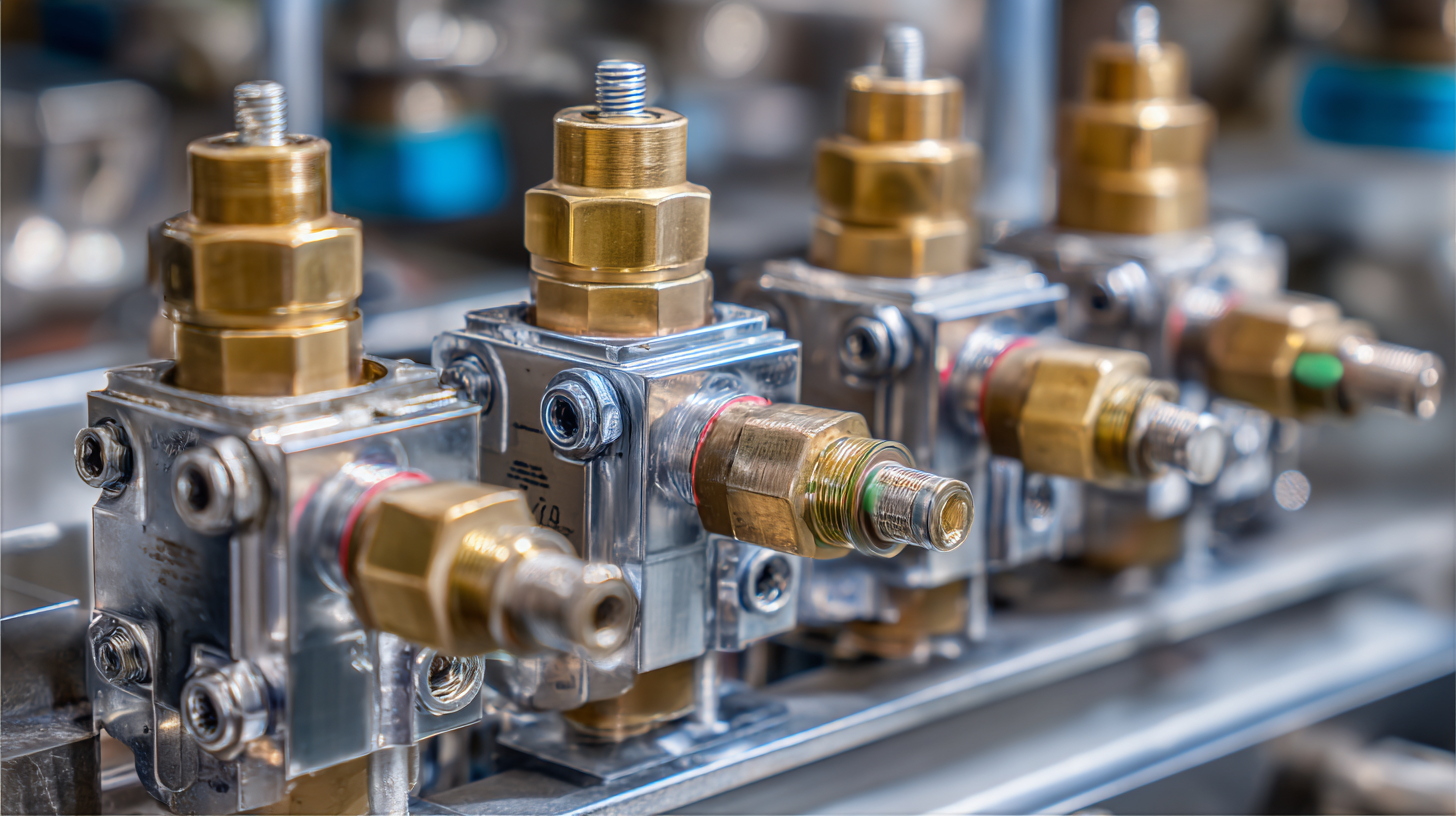

How to Select the Right Continental Hydraulic Valve for Your System

When selecting the right Continental hydraulic valve for your system, it’s essential to consider several critical factors to optimize performance and efficiency. According to a recent industry report from Grand View Research, the global hydraulics market is expected to reach $60 billion by 2028, indicating a growing reliance on effective hydraulic systems in various applications. To ensure the correct valve is chosen, assess the pressure rating, flow capacity, and operational environment. High-pressure applications often necessitate valves with robust construction, like the Continental series known for their durability and reliability.

Furthermore, compatibility with existing hydraulic components is key. According to the International Society for Automation (ISA), improper valve selection can lead to up to 30% energy losses in hydraulic systems. This underscores the importance of evaluating factors such as port size, connection types, and media compatibility. By taking these elements into account and utilizing the extensive technical resources available through Continental, engineers can make informed decisions that enhance system efficiency and reduce operational costs.

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

This chart illustrates the distribution of various types of hydraulic valves used in modern industrial applications. The data shows the percentage share of each valve type, highlighting the importance of selecting the right valve for specific system requirements.

Maintenance Tips for Ensuring Longevity of Continental Hydraulic Valves

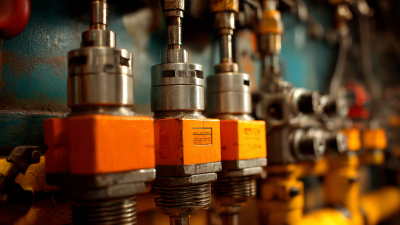

Maintaining the longevity of Continental hydraulic valves is crucial for optimal performance in various industrial applications. Regular inspection is paramount; operators should check for signs of wear, leaks, or other anomalies that could indicate potential failures. It is advisable to develop a routine maintenance schedule that includes a thorough examination of seals, housings, and connect points, as identifying issues early can prevent costly downtime and repairs.

Another key aspect of maintenance is ensuring that the hydraulic fluid used is clean and free from contaminants. Contaminated fluid can lead to valve malfunction and reduced efficiency. Operators should replace filters as recommended and follow proper fluid handling procedures to minimize exposure to dirt and debris. Furthermore, monitoring operating temperatures and pressures can help anticipate mechanical problems before they escalate, thereby extending the life of hydraulic valves and supporting the overall health of the hydraulic system.

Common Issues and Troubleshooting Techniques for Hydraulic Valve Performance

Hydraulic valves are crucial components in various industrial applications, controlling the flow and direction of hydraulic fluids. However, they can encounter several common issues that may impact their performance. One prevalent problem is leakage, which can occur due to wear and tear on seals or improper installation. Detecting a leak early is vital, as it can lead to decreased efficiency and increased operational costs. Regular inspection and maintenance can help identify potential leaks before they escalate into significant failures.

Hydraulic valves are crucial components in various industrial applications, controlling the flow and direction of hydraulic fluids. However, they can encounter several common issues that may impact their performance. One prevalent problem is leakage, which can occur due to wear and tear on seals or improper installation. Detecting a leak early is vital, as it can lead to decreased efficiency and increased operational costs. Regular inspection and maintenance can help identify potential leaks before they escalate into significant failures.

Another issue is valve responsiveness, which can be affected by factors such as contamination within the hydraulic fluid or improper tuning of the system. Contaminants can cause sticking or sluggish valve action, impacting overall machine performance. To troubleshoot this, operators should conduct routine checks of the hydraulic fluid quality and the cleanliness of the system. Adjusting the system settings and ensuring proper filtration can often restore optimal responsiveness. By addressing these common issues with effective troubleshooting techniques, industries can maintain the reliability and efficiency of hydraulic systems, ensuring uninterrupted operation and productivity.

Related Posts

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Choose the Right Hydraulic Check Valve for Your System

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

skip to Main Content

skip to Main Content