Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

The hydraulic solenoid valves play a pivotal role in modern hydraulic systems, offering precise control and enhancing operational efficiency across various industries. According to a report by MarketsandMarkets, the global hydraulic valves market is projected to reach $8.5 billion by 2026, driven largely by the increasing demand for automation and advanced machinery. As industries strive to optimize performance, understanding the efficiency of hydraulic solenoid valves becomes paramount.

Performance data indicates that well-designed solenoid valves can improve system responsiveness by up to 30%, thereby minimizing energy consumption and response time. Furthermore, advancements in technology are leading to the development of smart solenoid valves, capable of real-time diagnostics and performance monitoring, which enhances reliability and reduces downtime. As we delve into the latest industry trends and performance metrics, it becomes evident that the evolution of hydraulic solenoid valves is crucial to achieving higher efficiency and sustainability in hydraulic systems.

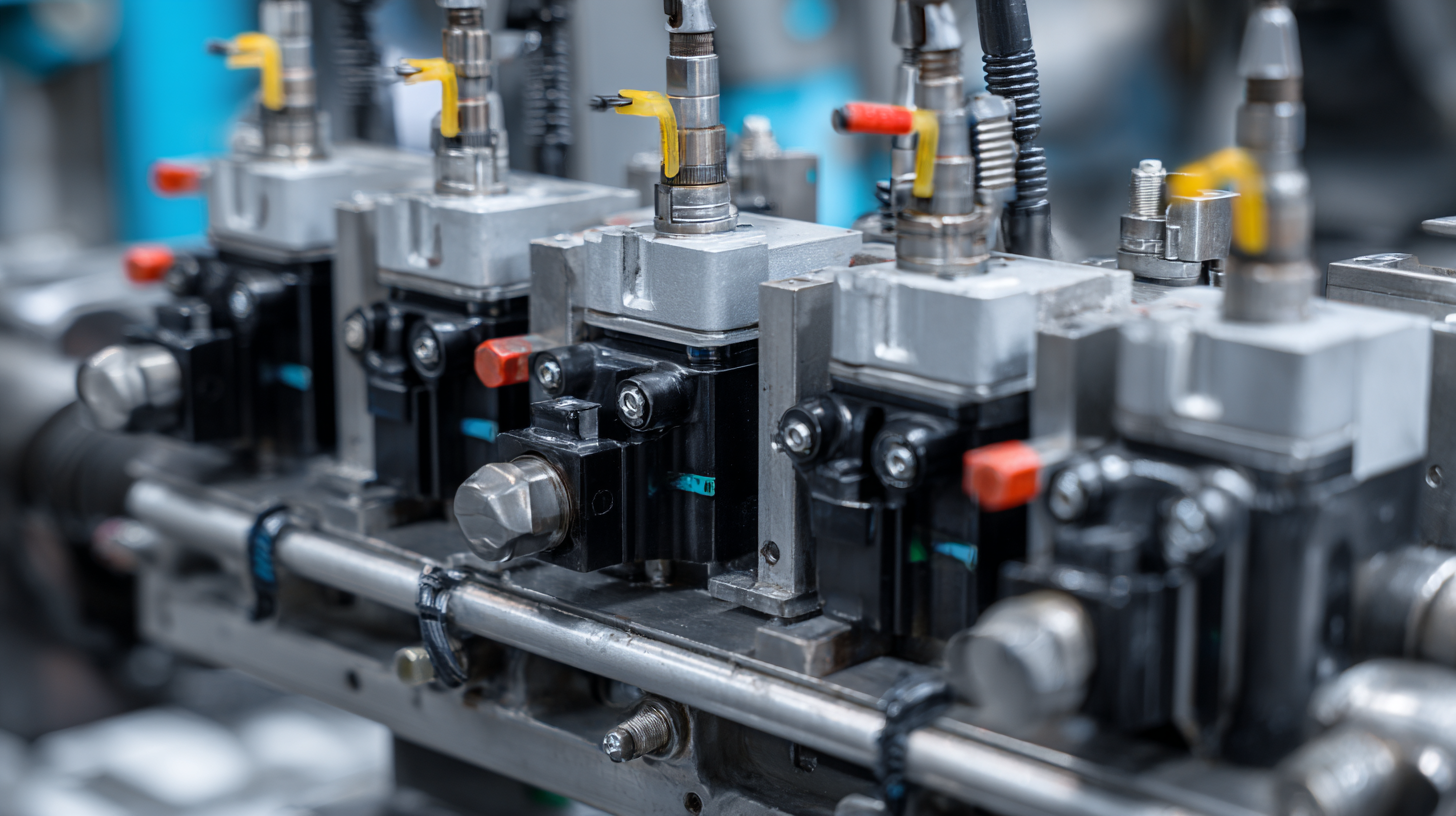

Understanding the Basics of Hydraulic Solenoid Valves and Their Functionality

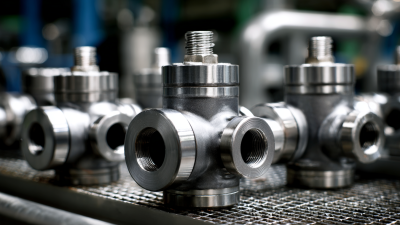

Hydraulic solenoid valves play a crucial role in the hydraulic systems of various applications, including high-performance environments like Formula 1 racing. These valves are integral to managing fluid flow and pressure within a hydraulic circuit, allowing for precise control of multiple sub-systems in a car. The operation of these valves relies on electromagnetic forces to open or close the flow paths, which contributes to the efficiency and responsiveness required in high-stakes automotive engineering.

Moreover, the recent expansion in hydraulic valve portfolios highlights the growing recognition of direct operated solenoid valves as essential components in modern hydraulic systems. Incorporating these valves enhances performance by improving control accuracy and reliability. As industries continue to seek advancements in hydraulic technology, understanding the functionality of solenoid valves becomes paramount. This knowledge can help engineers design more efficient systems that meet the evolving demands of various sectors, including automotive and manufacturing.

Key Factors Affecting the Efficiency of Hydraulic Solenoid Valves

Hydraulic solenoid valves play a crucial role in controlling fluid flow in various industrial applications. The efficiency of these valves can be influenced by several key factors. One significant aspect is the design of the solenoid itself, which impacts the response time and power consumption. Advanced designs often incorporate features such as low power coils and optimized magnetic circuits to enhance performance. Additionally, the choice of materials used in valve components can affect durability and resistance to wear, thereby influencing long-term efficiency.

Hydraulic solenoid valves play a crucial role in controlling fluid flow in various industrial applications. The efficiency of these valves can be influenced by several key factors. One significant aspect is the design of the solenoid itself, which impacts the response time and power consumption. Advanced designs often incorporate features such as low power coils and optimized magnetic circuits to enhance performance. Additionally, the choice of materials used in valve components can affect durability and resistance to wear, thereby influencing long-term efficiency.

Regular maintenance is also essential for ensuring optimal performance. Over time, debris and contaminants can accumulate, leading to reduced flow rates and increased energy consumption. Implementing a routine inspection schedule can help identify these issues before they escalate.

Tip: Always keep the valve and surrounding components clean and verify the solenoid operation to promote longevity and prevent unplanned downtime. Another helpful practice is to select valves that can accommodate varying pressure conditions in your application, as this flexibility often leads to improved efficiency in varying operational scenarios.

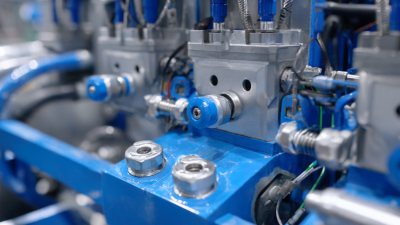

Comparative Analysis of Industry Performance Trends in Hydraulic Solenoid Valves

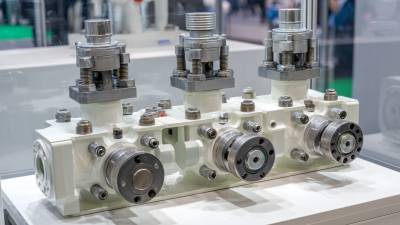

The hydraulic solenoid valve industry has seen significant advancements in efficiency and performance over the last few years. According to a recent report by Research and Markets, the hydraulic solenoid valve market is projected to grow by 4.2% annually through 2025, driven by increased automation in industrial applications. Notably, manufacturers are now focusing on reducing energy consumption while enhancing response times, which is crucial for optimizing system performance in hydraulic applications.

When analyzing performance trends, data from MarketWatch indicates that newer models of hydraulic solenoid valves demonstrate a 15% increase in operational efficiency compared to older versions. This improvement is largely due to advancements in materials and electronics, which contribute to faster actuation speeds and lower power requirements. Users are advised to consider these performance metrics when selecting valves, as efficiency directly correlates with long-term operational costs.

**Tips:** When investing in hydraulic solenoid valves, pay attention to manufacturers' specifications on energy efficiency and response times. Additionally, opting for valves with advanced sealing technology can help minimize leaks and ensure smoother operation, ultimately enhancing overall system performance. Regular maintenance checks can also prolong the lifespan of these components, thereby maintaining their efficiency.

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

| Valve Type | Operating Pressure (bar) | Response Time (ms) | Flow Rate (L/min) | Power Consumption (W) | Temperature Range (°C) |

|---|---|---|---|---|---|

| Direct Acting | 0-200 | 25 | 30 | 10 | -20 to 80 |

| Pilot Operated | 0-400 | 50 | 60 | 8 | -40 to 100 |

| Submersible | 0-250 | 30 | 45 | 12 | -10 to 90 |

| High Cycle | 0-300 | 20 | 50 | 15 | -20 to 70 |

| Low Voltage | 0-150 | 35 | 25 | 5 | -10 to 60 |

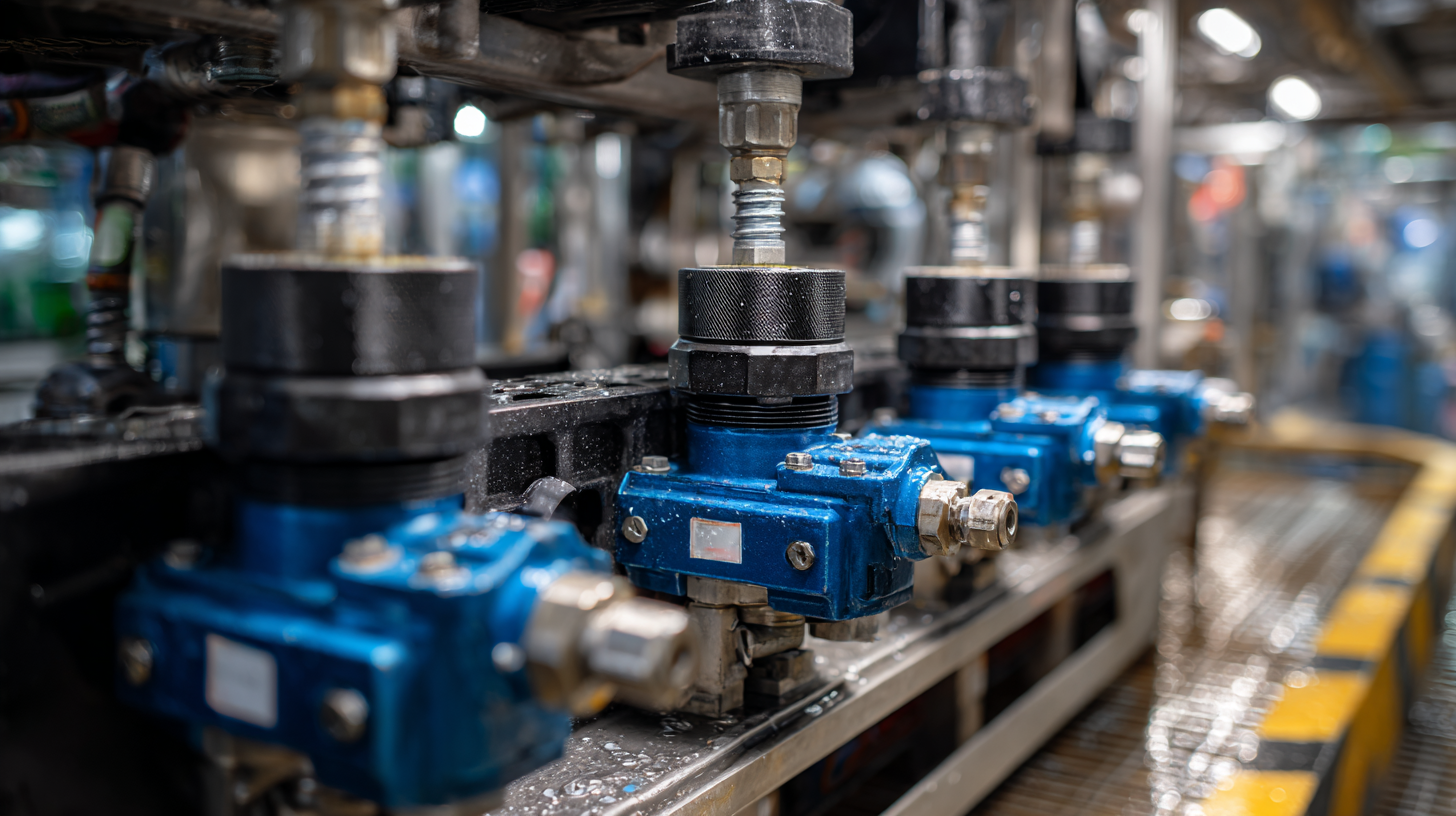

Best Practices for Optimizing the Performance of Hydraulic Solenoid Valves

To optimize the performance of hydraulic solenoid valves, it's essential to adopt best practices that focus on both maintenance and operational efficiency. Regular maintenance schedules should be established to inspect the valves for wear and tear, ensuring that seals and coils are functioning correctly. Additionally, maintaining clean hydraulic fluid is crucial to prevent contamination, which can lead to failures and inefficiencies. Implementing filtration systems can help in reducing particles that affect the performance of solenoid valves.

Furthermore, proper selection and sizing of valves are vital in maximizing efficiency. Using valves that are appropriately rated for the specific hydraulic system’s pressure and flow requirements can minimize energy loss and enhance responsiveness. It's also beneficial to periodically review and analyze the system's performance data. By monitoring trends and identifying potential issues early, operators can make informed adjustments that improve the overall reliability and efficiency of hydraulic systems.

Regular training for personnel on these practices can foster a deeper understanding of the systems they manage, further enhancing performance outcomes.

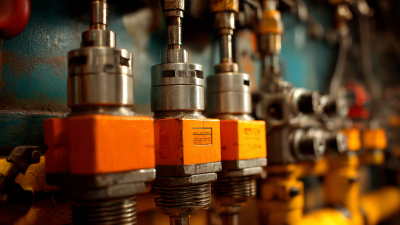

Future Innovations and Trends in Hydraulic Solenoid Valve Technology

The hydraulic solenoid valve market is witnessing significant innovations that aim to enhance efficiency and performance. With the rise of automation in various industries, manufacturers are focusing on developing smarter solenoid valves equipped with advanced sensors and connectivity features. These innovations enable real-time monitoring and diagnostics, allowing for predictive maintenance and reducing downtime. Consequently, industries can optimize their operations, leading to increased productivity and reduced operational costs.

Furthermore, the integration of eco-friendly materials and energy-efficient designs is shaping the future of hydraulic solenoid technology. As sustainability becomes a priority for many companies, the development of valves that minimize hydraulic fluid leakage and consume less power is gaining traction. Additionally, the trends indicate a move towards compact and lightweight designs, which not only improve installation flexibility but also enhance the overall system performance. As these advancements continue to emerge, the hydraulic solenoid valve industry is poised for a transformative phase that blends efficiency with sustainability.

Efficiency of Hydraulic Solenoid Valves: Performance Metrics

This chart illustrates various performance metrics of hydraulic solenoid valves, highlighting their flow rate, response time, energy consumption, and durability. These factors are critical in evaluating the efficiency and effectiveness of solenoid valves in various industrial applications.

Related Posts

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

Why Investing in High-Quality Check Valves Can Reduce Operational Costs by Up to 30%

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

skip to Main Content

skip to Main Content