Understanding the Importance of Directional Control Valves in Fluid Power Systems

In the realm of fluid power systems, directional control valves play a pivotal role in determining the flow and functionality of hydraulic and pneumatic applications. These essential components guide the direction of fluid movement, ensuring that machinery operates smoothly and efficiently. Understanding the importance of directional control valves is crucial for engineers and technicians who design and maintain these systems. With the right knowledge and application of these valves, users can optimize performance, enhance safety, and reduce operational costs. This article will delve into practical tips for selecting, installing, and troubleshooting directional control valves, highlighting their significance in achieving reliable and effective fluid power system operations. By the end, readers will be equipped with valuable insights that can improve their understanding and application of these vital components.

What Are Directional Control Valves and Their Functions in Fluid Systems

Directional control valves are crucial components in fluid power systems, governing the flow of hydraulic or pneumatic fluids to various actuator devices. These valves can dictate the direction of fluid flow, effectively controlling machine movements in industrial applications, mobile machinery, and automotive systems. According to a recent report by the Fluid Power Educational Foundation, the global market for directional control valves is projected to reach $6.5 billion by 2025, underscoring their essential role in modern engineering.

The primary function of directional control valves is to manage the path taken by the fluid within a system. They can switch between different flow paths through various configurations such as two-way, three-way, and four-way valves. For example, in a hydraulic press, a four-way valve may control the up and down movement of the pressing arm, allowing for precise operation based on system demands. In 2022, it was reported that approximately 57% of fluid power systems relied on efficient directional control mechanisms to enhance performance and reliability, illustrating their importance in achieving optimal operational efficiency across various sectors.

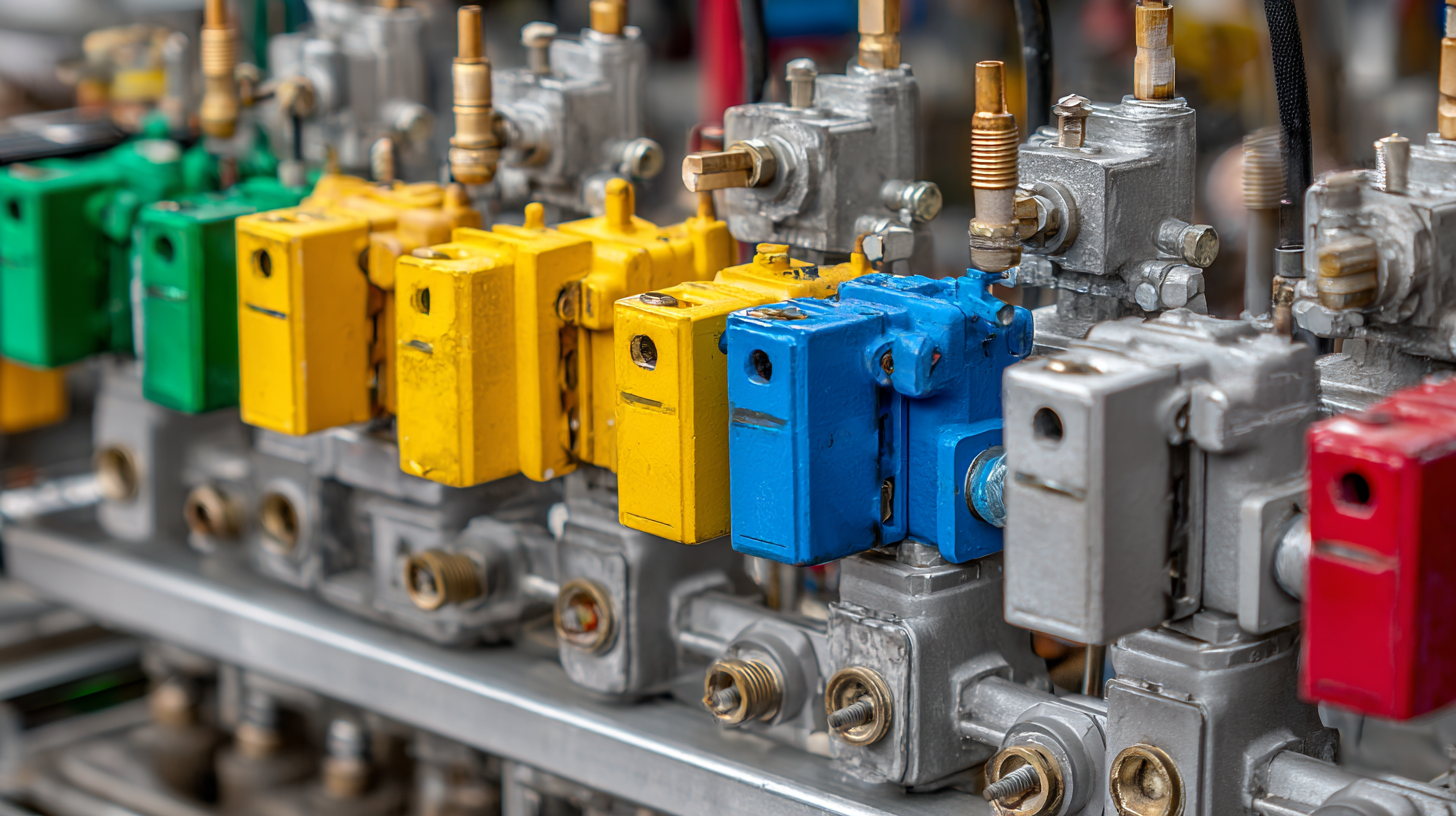

Types of Directional Control Valves: An Overview of Available Options

Directional control valves are vital components in fluid power systems, as they regulate the flow direction of fluid, allowing for precise control of hydraulic and pneumatic actuators. Understanding the different types of directional control valves is essential for optimizing performance and ensuring the efficiency of your system.

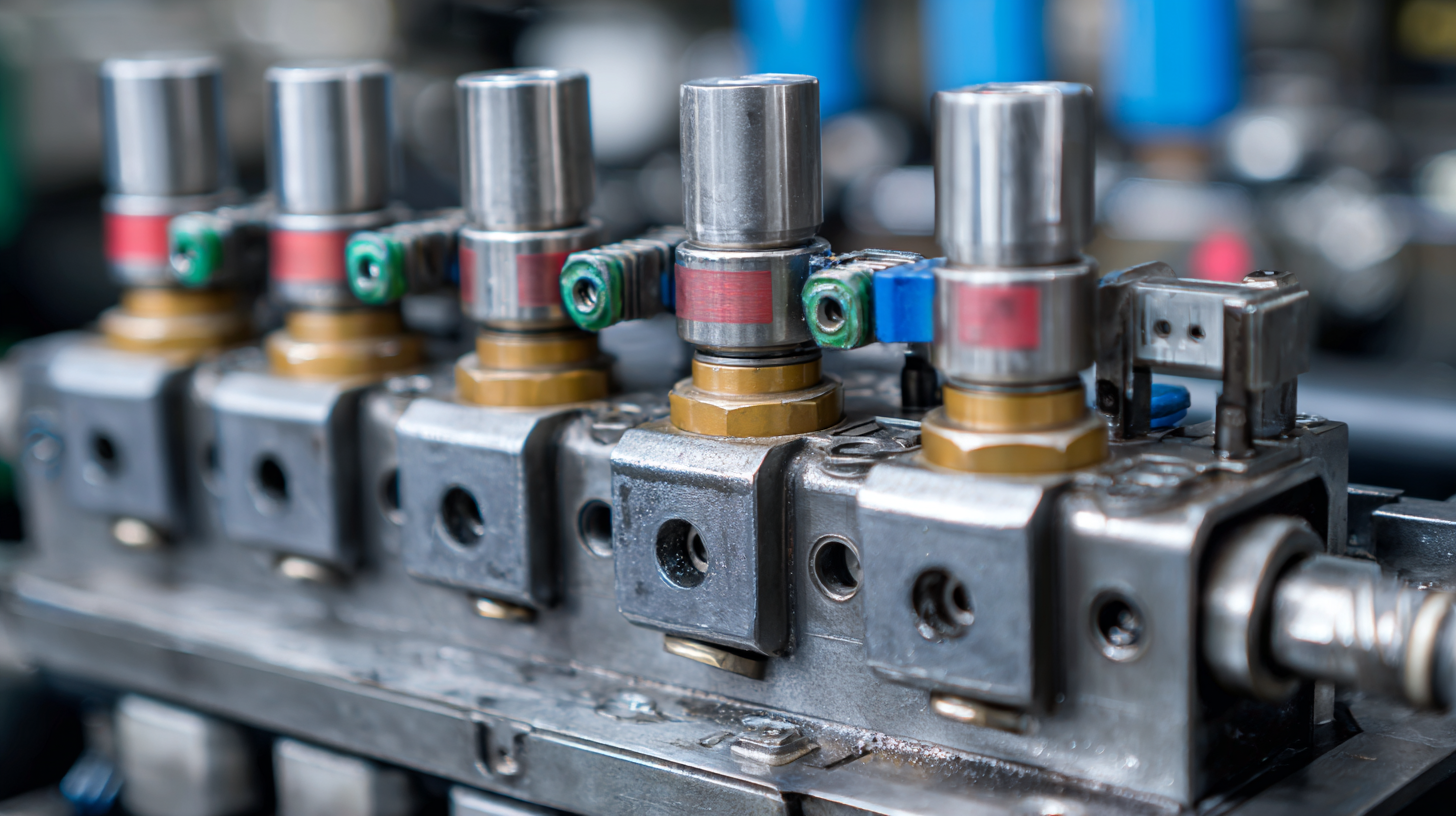

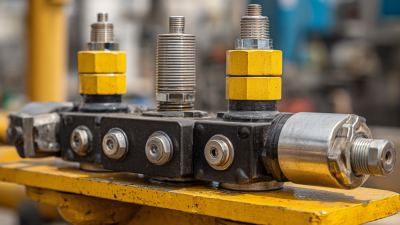

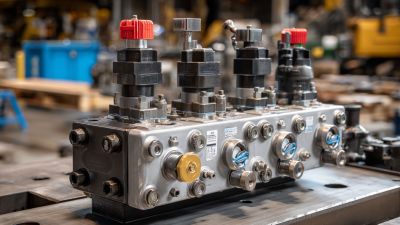

There are several types of directional control valves, including spool valves, poppet valves, and cartridge valves. Spool valves are versatile and commonly used, featuring an elongated spool that shifts within a cylinder to direct fluid flow. Poppet valves, on the other hand, employ a simple design where a poppet seal opens or closes to control flow, making them ideal for high-pressure applications. Cartridge valves combine the benefits of both spool and poppet designs into a compact unit, suitable for modular hydraulic systems.

Tips: When selecting a directional control valve, consider factors such as flow rate, pressure rating, and the specific application needs. Additionally, ensure compatibility with your existing components to prevent issues down the line. Regular maintenance of these valves is crucial to prolong their lifespan and maintain system efficiency. Always consult technical specifications to make informed decisions tailored to your fluid power system.

How Directional Control Valves Influence Fluid Flow and Pressure Control

Directional control valves play a critical role in fluid power systems by regulating the flow and direction of hydraulic or pneumatic fluids. These valves determine the path that fluid takes through the system, enabling operators to control the movement of actuators, such as cylinders and motors. By influencing the flow direction, directional control valves not only facilitate machine operations but also ensure that systems operate safely and efficiently. The ability to choose different flow paths allows for the simultaneous operation of multiple components, enhancing overall functionality.

Directional control valves play a critical role in fluid power systems by regulating the flow and direction of hydraulic or pneumatic fluids. These valves determine the path that fluid takes through the system, enabling operators to control the movement of actuators, such as cylinders and motors. By influencing the flow direction, directional control valves not only facilitate machine operations but also ensure that systems operate safely and efficiently. The ability to choose different flow paths allows for the simultaneous operation of multiple components, enhancing overall functionality.

In addition to controlling flow direction, these valves are integral to managing pressure within fluid systems. By adjusting the flow rate and enabling pressure relief, directional control valves help maintain optimal operating conditions. This capability is crucial in preventing system overloads and ensuring longevity and reliability of the machinery involved. Whether in industrial applications or mobile machinery, the precise control of fluid flow and pressure afforded by directional control valves is essential for achieving desired performance outcomes and operational efficiency.

Key Applications of Directional Control Valves in Various Industries

Directional control valves play a crucial role in fluid power systems by managing the flow of hydraulic or pneumatic fluids in various industrial applications. One key application is in construction machinery, where these valves enable precise movement of equipment such as excavators and cranes. By controlling the direction of fluid flow, operators can efficiently maneuver heavy loads and execute complex tasks, enhancing productivity on job sites.

In the automotive sector, directional control valves are essential in systems like power steering and anti-lock braking systems (ABS). These valves allow for responsive adjustments to fluid flow, ensuring that the vehicle can safely and effectively navigate various driving conditions. Additionally, in the manufacturing industry, they are employed in automated assembly lines, where they facilitate the operation of robotic arms and other machinery, contributing to streamlined production processes and improved efficiency. The versatility of directional control valves highlights their significance across multiple sectors, driving advancements in technology and operational capabilities.

Understanding the Importance of Directional Control Valves in Fluid Power Systems - Key Applications of Directional Control Valves in Various Industries

| Industry | Key Applications | Type of Directional Control Valve | Functionality |

|---|---|---|---|

| Manufacturing | CNC Machines, Robotic Arms | 4/2 and 5/2 Valves | Manage actuator movements |

| Construction | Excavators, Loaders | 3/2 Valves | Control attachment functions |

| Agriculture | Tractors, Harvesters | Electro-hydraulic Valves | Automate implements |

| Mining | Drilling Equipment, Loaders | Directional Control Valves | Direct fluid flow in heavy machines |

| Transportation | Buses, Trucks | Pilot-operated Valves | Control braking and steering |

Maintenance and Troubleshooting of Directional Control Valves in Systems

Directional control valves play a crucial role in fluid power systems by directing the flow of fluid to different actuators, ensuring that machinery operates efficiently and as intended. However, like any mechanical component, these valves can encounter issues over time. Regular maintenance is key to prolonging their lifespan and performance. It's essential to conduct routine inspections for leaks and wear, ensuring that seals and O-rings are in good condition. Keeping the valve clean and free from contaminants ensures smooth operation and avoids unnecessary strain on the system.

Directional control valves play a crucial role in fluid power systems by directing the flow of fluid to different actuators, ensuring that machinery operates efficiently and as intended. However, like any mechanical component, these valves can encounter issues over time. Regular maintenance is key to prolonging their lifespan and performance. It's essential to conduct routine inspections for leaks and wear, ensuring that seals and O-rings are in good condition. Keeping the valve clean and free from contaminants ensures smooth operation and avoids unnecessary strain on the system.

Tips: Always refer to the manufacturer's guidelines for the specific maintenance schedule recommended for your directional control valves. Additionally, using a suitable lubricant can enhance performance and prevent unnecessary friction between moving parts. If troubleshooting is necessary, check for signs of valve malfunction, such as erratic movement or failure to shift, and consider using diagnostic tools to pinpoint issues effectively.

When troubleshooting, it's beneficial to consider the entire hydraulic circuit, as issues could originate from connected components. Assess the input pressure and flow rates, as fluctuations may indicate underlying problems. Ensuring that the valves are properly calibrated can resolve many operational issues, leading to improved efficiency and reliability in your fluid power system.

Related Posts

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Exploring the Synergy of Pneumatic and Hydraulic Systems in Modern Industrial Applications

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

skip to Main Content

skip to Main Content