How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

Choosing the right hydraulic pressure relief valve is crucial for ensuring the efficiency and safety of hydraulic systems in various industrial applications. According to a report by MarketsandMarkets, the hydraulic valve market is projected to reach USD 26.06 billion by 2026, demonstrating the significant role these components play in machinery performance and operational safety.

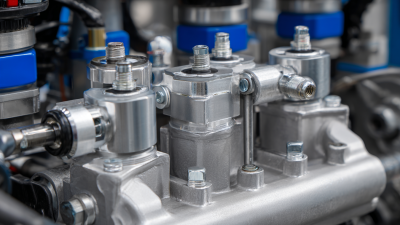

Hydraulic pressure relief valves are essential for preventing system overloads, maintaining desired pressure levels, and protecting against potential failures.

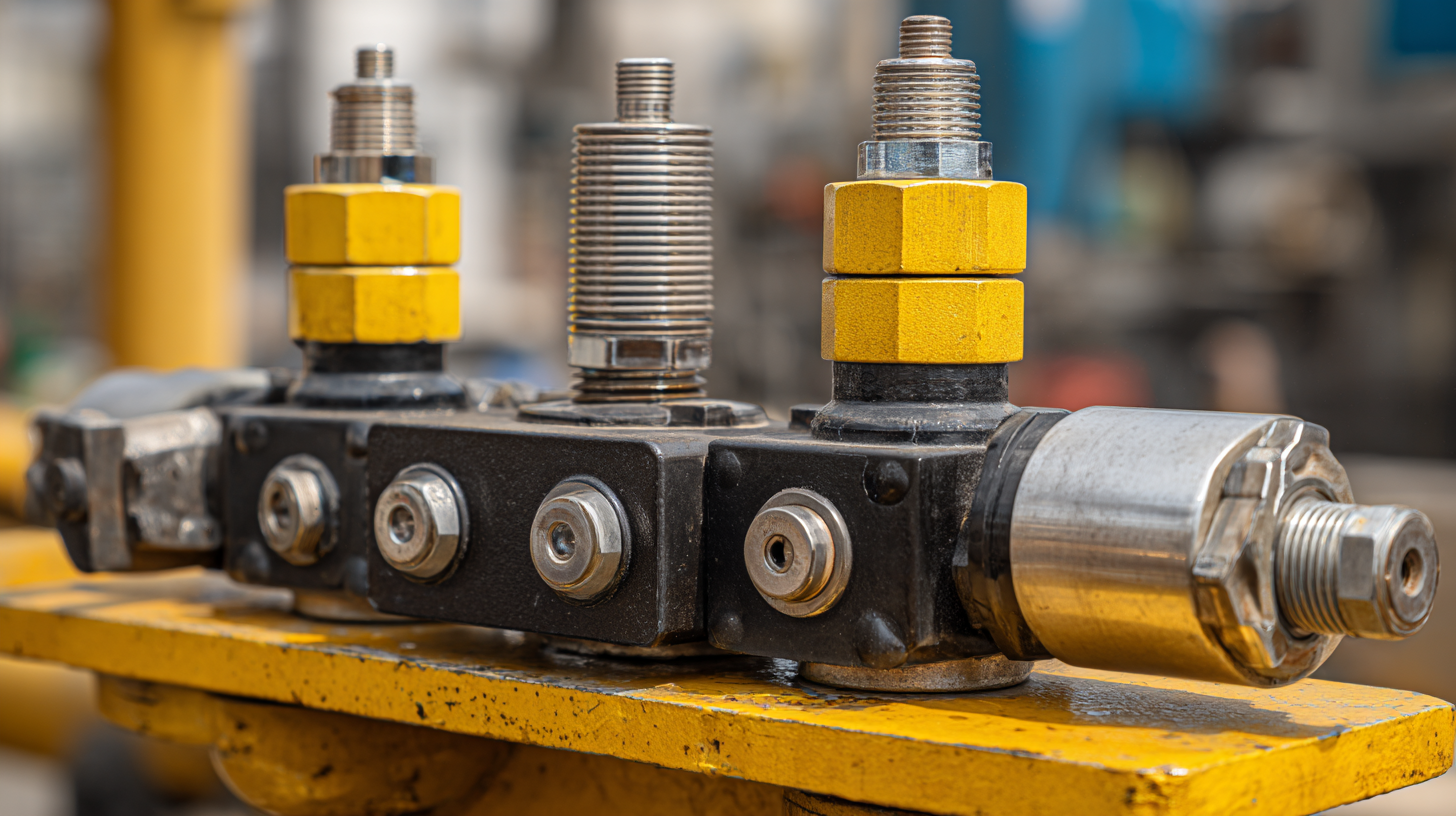

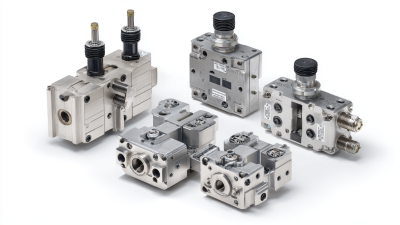

The diverse range of models available, each tailored for specific applications and operating conditions, makes selecting the appropriate valve a complex yet vital task.

As industries increasingly prioritize reliability and performance, understanding the mechanisms, specifications, and applications of hydraulic pressure relief valves becomes imperative for engineers and technicians alike.

Choosing the right hydraulic pressure relief valve is crucial for ensuring the efficiency and safety of hydraulic systems in various industrial applications. According to a report by MarketsandMarkets, the hydraulic valve market is projected to reach USD 26.06 billion by 2026, demonstrating the significant role these components play in machinery performance and operational safety.

Hydraulic pressure relief valves are essential for preventing system overloads, maintaining desired pressure levels, and protecting against potential failures.

The diverse range of models available, each tailored for specific applications and operating conditions, makes selecting the appropriate valve a complex yet vital task.

As industries increasingly prioritize reliability and performance, understanding the mechanisms, specifications, and applications of hydraulic pressure relief valves becomes imperative for engineers and technicians alike.

Understanding the Different Types of Hydraulic Pressure Relief Valves and Their Applications

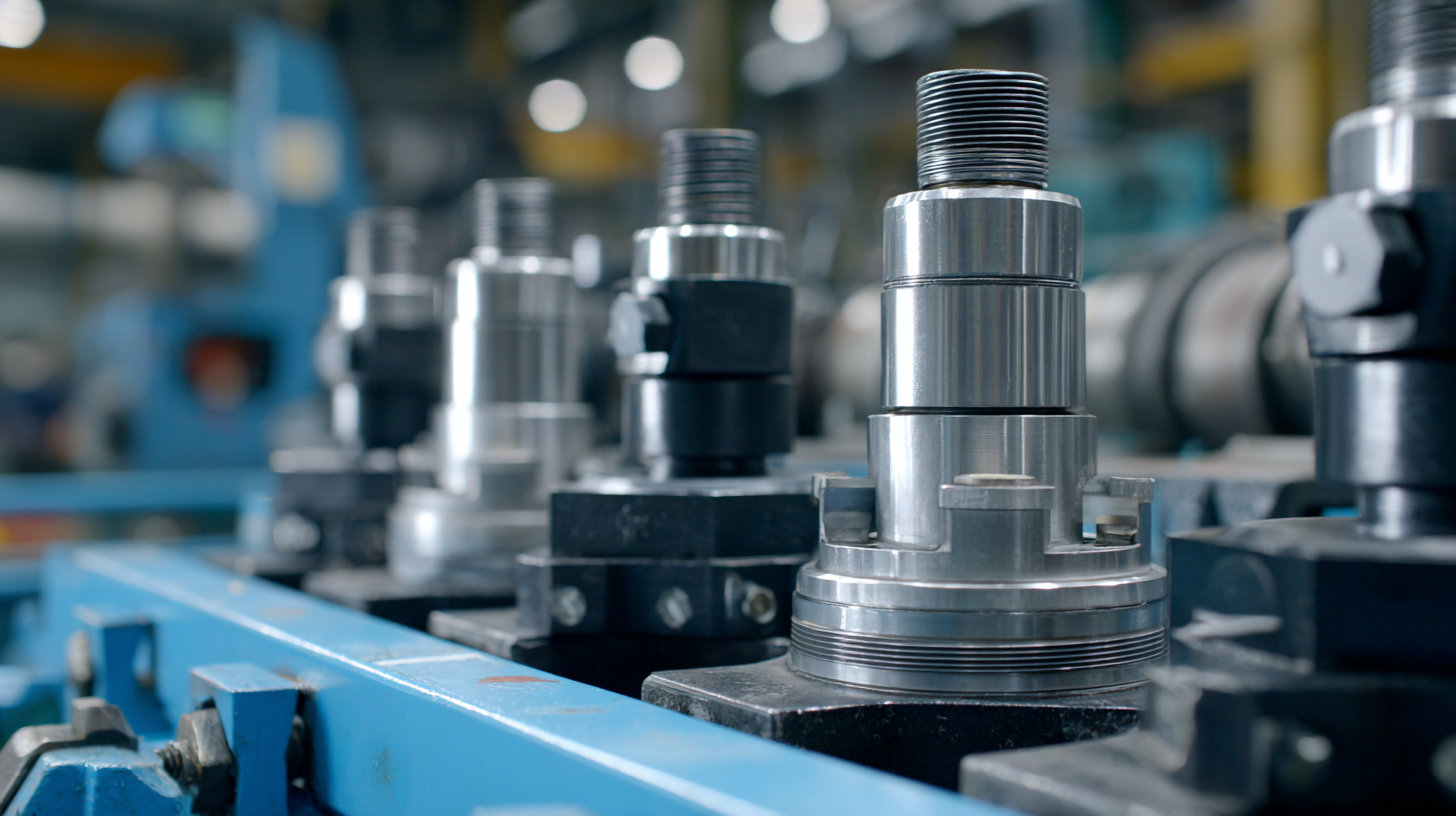

When choosing a hydraulic pressure relief valve, it's essential to understand the different types and their specific applications. There are three primary types: spring-loaded valves, pilot-operated valves, and proportional relief valves. According to a report by the Fluid Power Institute, spring-loaded valves are the most commonly used due to their simplicity and reliability, suitable for basic hydraulic systems where precise pressure control is not critical. They operate by using a spring to maintain a set pressure, making them ideal for low to moderate pressure applications.

In contrast, pilot-operated relief valves provide more accurate pressure regulation, making them suitable for high-pressure systems that require precise control. These valves utilize system pressure to assist in opening and closing, allowing them to handle larger flow rates and higher pressures efficiently. The Hydraulic Equipment Manufacturers Association (HEMA) highlights that pilot-operated valves are crucial in applications like hydraulic presses and heavy machinery, where safety and efficiency are paramount. Meanwhile, proportional relief valves offer adjustable pressure settings that can be modified electronically, making them perfect for complex systems that demand versatility. As industries continue to advance, selecting the right type of valve becomes increasingly vital to ensure safety and efficiency in hydraulic operations.

Hydraulic Pressure Relief Valve Types and Their Common Applications

Key Factors to Consider When Selecting a Hydraulic Pressure Relief Valve

When selecting a hydraulic pressure relief valve for your application, it's crucial to consider several key factors to ensure optimal performance and safety. Firstly, understanding the system's maximum operating pressure is essential. According to industry reports like those from the National Fluid Power Association (NFPA), many hydraulic system failures stem from inadequate pressure relief mechanisms. A relief valve should be set slightly above this maximum operating pressure to effectively protect the system without compromising efficiency.

Another critical factor is the flow capacity of the valve. The correct sizing of a hydraulic pressure relief valve can significantly impact overall system performance. Data from the Hydraulic Institute suggests that improperly sized valves can lead to pressure spikes, which may damage system components. It’s vital to calculate the flow requirements accurately, taking into account both the maximum flow rate during operation and the worst-case scenarios.

Tips: Always refer to the manufacturer’s specifications when selecting a valve. Additionally, consider the valve's response time; faster response times can prevent pressure surges effectively. Regular maintenance checks are also recommended to ensure the valve operates correctly over time and to avoid costly system downtimes.

Analyzing System Pressure Profiles to Optimize Valve Performance

When selecting a hydraulic pressure relief valve, understanding the system's pressure profiles is crucial to optimizing valve performance. An analysis of pressure fluctuations within hydraulic systems reveals that consistent monitoring can lead to significant efficiency gains. According to a report by the Hydraulic Institute, improperly calibrated relief valves can result in

up to 30% energy losses in hydraulic systems, emphasizing the importance of fine-tuning valve settings based on detailed pressure profiles.

To effectively analyze these profiles, leveraging data from advanced pressure monitoring tools can provide insights into peak pressure points and frequent surges. Research indicates that valves designed with adaptive response capabilities can adjust to varying pressure conditions, thereby maintaining system integrity and enhancing operational safety. The International Fluid Power Society states that systems characterized by dynamic pressure changes may benefit from proportional relief valves, which can modulate the discharge based on real-time pressure data. This tailored approach not only prolongs equipment life but also facilitates more robust system performance overall.

Evaluating Material Compatibility for Longevity and Safety in Hydraulic Systems

When selecting a hydraulic pressure relief valve, assessing material compatibility is crucial for ensuring longevity and safety in hydraulic systems. According to a report by the Hydraulic Institute, compatibility between the valve materials and the hydraulic fluids used can significantly impact the performance and lifespan of the system. For instance, using a valve made from brass or stainless steel can prevent corrosion when exposed to hydraulic fluids, which commonly contain additives that could deteriorate incompatible materials.

When selecting a hydraulic pressure relief valve, assessing material compatibility is crucial for ensuring longevity and safety in hydraulic systems. According to a report by the Hydraulic Institute, compatibility between the valve materials and the hydraulic fluids used can significantly impact the performance and lifespan of the system. For instance, using a valve made from brass or stainless steel can prevent corrosion when exposed to hydraulic fluids, which commonly contain additives that could deteriorate incompatible materials.

Moreover, the American Society of Mechanical Engineers (ASME) highlights the importance of considering temperature and chemical exposure when choosing materials for hydraulic components. Valves subjected to high temperatures may require materials such as high-performance polymers or specialty alloys to mitigate wear and fatigue. Failure to account for these factors can lead to premature valve failure; studies indicate that over 30% of hydraulic system breakdowns are attributable to material incompatibility. Therefore, a comprehensive evaluation of material properties is essential not only for maximizing the operational life of hydraulic pressure relief valves but also for maintaining safety standards in the overall hydraulic system.

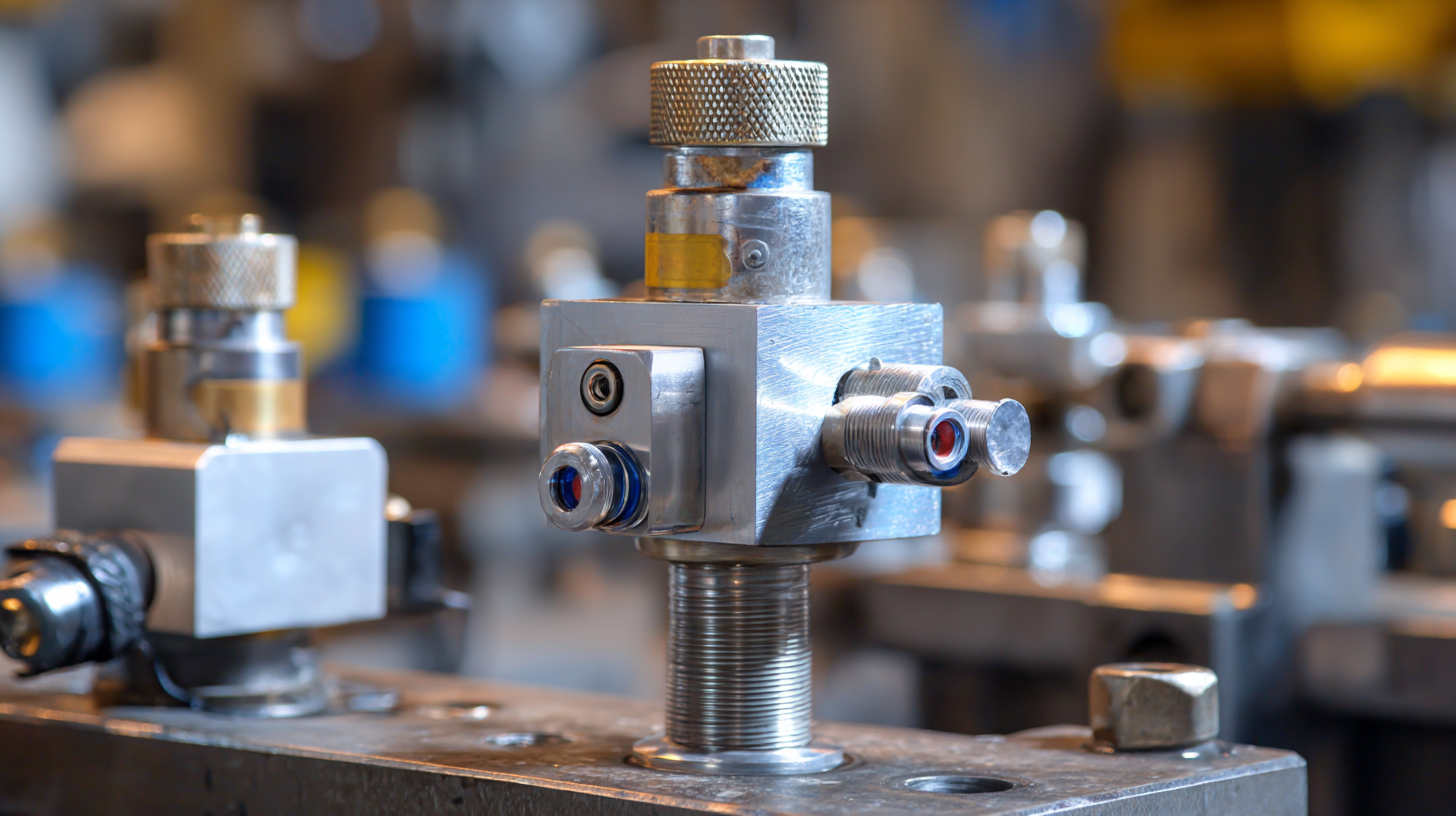

Measuring Flow Rate and Pressure Settings to Ensure Correct Valve Sizing

When selecting a hydraulic pressure relief valve, accurate measurement of flow rate and pressure settings is crucial for ensuring proper valve sizing. The flow rate, typically expressed in gallons per minute (GPM) or liters per minute (LPM), directly influences the size and capacity of the valve. An insufficiently sized valve can lead to inadequate pressure relief, potentially damaging the hydraulic system. In contrast, an oversized valve can create unnecessary pressure drops, affecting system efficiency.

To begin, it is essential to assess the maximum flow rate of the hydraulic system during operation. This involves measuring the flow under various conditions to establish a clear understanding of the system's needs. Alongside flow rate, determining the operational pressure settings is equally important. This includes both the system's maximum allowable pressure and the normal operating pressure, which helps in selecting a relief valve that opens and closes at the correct threshold. By meticulously measuring these parameters, one can ensure that the right valve is chosen, optimizing performance and prolonging the life of the hydraulic system.

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application - Measuring Flow Rate and Pressure Settings to Ensure Correct Valve Sizing

| Application | Flow Rate (GPM) | Set Pressure (PSI) | Valve Size (Inches) | Actuation Type |

|---|---|---|---|---|

| Hydraulic Press | 15 | 3000 | 1.5 | Spring-loaded |

| Excavator | 25 | 3500 | 2.0 | Pilot-operated |

| Injection Molding | 10 | 2500 | 1.0 | Spring-loaded |

| Mobile Lift | 20 | 2800 | 1.5 | Pilot-operated |

| Agricultural Equipment | 30 | 3200 | 2.5 | Spring-loaded |

Related Posts

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

7 Best Pressure Reducing Valves You Should Consider for Optimal Performance

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

How to Optimize Your System with Automated Valves for Maximum Efficiency

skip to Main Content

skip to Main Content