2025 How to Choose the Right Flow Valves for Your Industrial Needs

In the world of industrial processes, the selection of appropriate components is crucial for ensuring efficiency and reliability. Among these critical components, flow valves play a pivotal role in managing the flow of fluids, whether in manufacturing, chemical processing, or other industrial applications. These devices not only control the volume and pressure of fluid flow but also contribute to the safety and performance of the entire system. As industries evolve and the demand for precision increases, understanding how to choose the right flow valves becomes essential.

When faced with a myriad of options available on the market, it is vital for engineers and decision-makers to assess their specific operational requirements carefully. Factors such as the type of fluid, temperature, pressure conditions, and the intended application must be taken into account to ensure optimal performance. This article will delve into the key considerations that should guide the selection of flow valves, providing valuable insights that will assist in making informed decisions tailored to diverse industrial needs. By understanding these elements, businesses can enhance their operational efficiency and reduce the likelihood of costly downtime, ultimately leading to greater success in their respective fields.

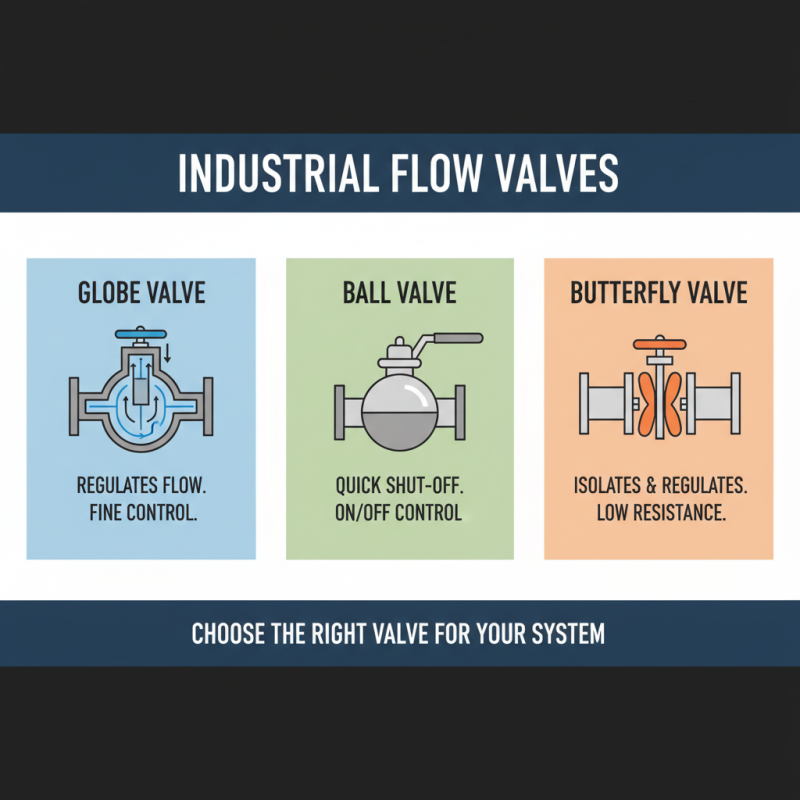

Understanding Different Types of Flow Valves for Industrial Applications

Flow valves are essential components in many industrial applications, controlling the direction and volume of fluid movement within systems. Understanding the different types of flow valves is crucial for selecting the right one for your specific needs. Common types of flow valves include globe valves, ball valves, and butterfly valves, each designed for particular functions and behaviors. Globe valves are ideal for regulating flow due to their design, which allows for fine control. Ball valves, on the other hand, offer quick shut-off capabilities and are suitable for on/off control, making them favored in systems requiring minimal resistance.

In addition to these, gate valves and check valves play important roles in industrial settings. Gate valves provide a straight flow path and are used primarily for isolation, while check valves prevent backflow, ensuring that fluid flows in only one direction. Each type of flow valve comes with its advantages and operational considerations, such as pressure drop, flow capacity, and maintenance needs. By understanding the specific applications and features of these various valves, you can make informed choices that enhance system efficiency and reliability, ultimately leading to improved performance in your industrial processes.

Key Specifications to Consider When Selecting Flow Valves

When selecting flow valves for industrial applications, several key specifications must be taken into account to ensure efficiency and reliability. First, consider the valve's flow characteristics, such as flow rate and pressure drop. Knowing the maximum and minimum flow requirements for your specific application will help in choosing a valve that optimally regulates the flow without unnecessary pressure loss. Additionally, evaluating the valve type—whether globe, gate, or ball—will affect both control precision and installation suitability.

Tips: Always check the materials of construction. The valve should be compatible with the fluids it will handle, whether they are corrosive, viscous, or subject to high temperatures. This compatibility not only extends the lifespan of the valve but also maintains system integrity.

Another critical specification is the size of the flow valve, which must match the pipe diameter in your system to prevent turbulence. Oversized or undersized valves may lead to inefficiencies, impacting performance and safety. Lastly, consider the actuation method, whether manual, electric, or pneumatic, as this will influence operational convenience and response times in automated systems. Selecting the right actuation method ensures seamless integration with existing processes and enhances overall system functionality.

2025 Flow Valves Selection Criteria

Evaluating Material Compatibility in Flow Valve Selection

When selecting flow valves for industrial applications, one of the critical factors to consider is material compatibility. The choice of valve material can significantly impact performance, longevity, and safety. Different media, such as gases, liquids, or slurries, have unique chemical and physical properties that interact with valve materials in various ways.

For instance, corrosive substances can degrade certain metals and plastics, leading to leaks or valve failure. Therefore, it is essential to analyze the chemical composition of the media to ensure the selected materials can withstand exposure without compromising integrity.

Additionally, temperature and pressure conditions must be evaluated alongside material compatibility. High temperatures can alter the mechanical properties of materials, potentially making them less effective in sealing or flow regulation. Meanwhile, pressure fluctuations can exacerbate the risks associated with incompatible materials, resulting in operational inefficiencies or accidents.

By conducting thorough assessments, including compatibility charts and expert consultations, industrial operators can select flow valves that not only meet their immediate functional requirements but also ensure safe and reliable long-term operation.

Assessing Pressure and Temperature Ratings for Optimal Performance

When selecting flow valves for industrial applications, understanding pressure and temperature ratings is essential for ensuring optimal performance and longevity. The American Society of Mechanical Engineers (ASME) emphasizes that the pressure rating must be compatible with the system's maximum operating pressure to prevent failures and leaks. Typically, valves are categorized by ANSI ratings ranging from 150 to 2500 psi. It is crucial to assess the specific application requirements alongside these ratings, as exceeding the recommended limits can lead to catastrophic failures.

Temperature ratings are equally important, as they dictate the material selection for the valves. According to recent industry reports by the Fluid Sealing Association, materials such as stainless steel are favored for high-temperature applications, often rated up to 1000°F, while other materials may not withstand such extremes. Industries operating at different temperatures must choose valves that not only handle the heat but also prevent thermal expansion that could lead to improper sealing.

Tips:

- Always cross-reference the specifications of your flow valves with the environmental conditions they will face, including shocks, vibrations, and atmospheric pressure changes.

- Keep in mind the compatibility of the valve materials with the fluids they will convey, especially in the case of corrosive or abrasive substances, to ensure durability and reliability over time.

Leveraging Industry Standards and Certifications in Flow Valve Choices

When selecting flow valves for industrial applications, understanding and leveraging industry standards and certifications is crucial. Standards such as ANSI/ISA-75.01.01 for control valves and API 609 for butterfly valves provide essential guidance on performance, reliability, and safety. These certifications not only ensure that the products meet specific operational requirements but also help in comparing different valve options effectively. According to a recent report by MarketsandMarkets, the global industrial valve market is projected to reach USD 86.2 billion by 2025, underlining the importance of adherence to recognized standards in an increasingly competitive environment.

Tips: Always check for relevant certifications such as ISO 9001 for quality management and CE marking for compliance with EU regulations. This practice not only mitigates risks associated with non-compliance but also assures that the selected valves will perform consistently under designated operational pressures and temperatures.

Additionally, choosing valves that comply with environmental and safety standards can lead to long-term cost savings and enhanced operational efficiency. A comprehensive evaluation of your specific application needs alongside these standards will ease procurement processes and help avoid costly mistakes. The industry’s continuous evolution, as highlighted by the International Society of Automation, emphasizes the necessity for modern facilities to stay updated with best practices in flow valve selection.

2025 How to Choose the Right Flow Valves for Your Industrial Needs - Leveraging Industry Standards and Certifications in Flow Valve Choices

| Flow Valve Type | Application | Material | Pressure Rating (psi) | Standards/Certifications |

|---|---|---|---|---|

| Ball Valve | General Purpose | Stainless Steel | 1500 | API 609, ASME B16.34 |

| Gate Valve | Water Supply | Ductile Iron | 250 | AWWA C509, MSS SP-70 |

| Globe Valve | Flow Regulation | Bronze | 600 | ASME B16.10, API 602 |

| Check Valve | Backflow Prevention | PVC | 150 | ASTM D1784, NSF 61 |

| Butterfly Valve | Flow Control | Cast Iron | 300 | API 609, AWWA C504 |

Related Posts

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency

-

Understanding the Benefits of Pilot Operated Check Valves in Fluid Control Systems

skip to Main Content

skip to Main Content