10 Tips for Choosing the Right Flow Valves for Your Business Needs

In today's industrial landscape, selecting the right flow valves is crucial for optimizing operational efficiency and ensuring system reliability. According to a report by MarketsandMarkets, the global flow valve market is projected to reach USD 80 billion by 2026, growing at a CAGR of 5.5% from 2021. This growth is primarily driven by the increasing demand for automation in various sectors, including oil and gas, water treatment, and manufacturing. Choosing the appropriate flow valves is not just a matter of functionality; it impacts safety, regulatory compliance, and long-term operational costs. With a plethora of options available, it can be overwhelming for businesses to make informed decisions. This article provides ten critical tips for businesses to consider when selecting flow valves, ensuring they meet specific application requirements while maximizing efficiency and cost-effectiveness.

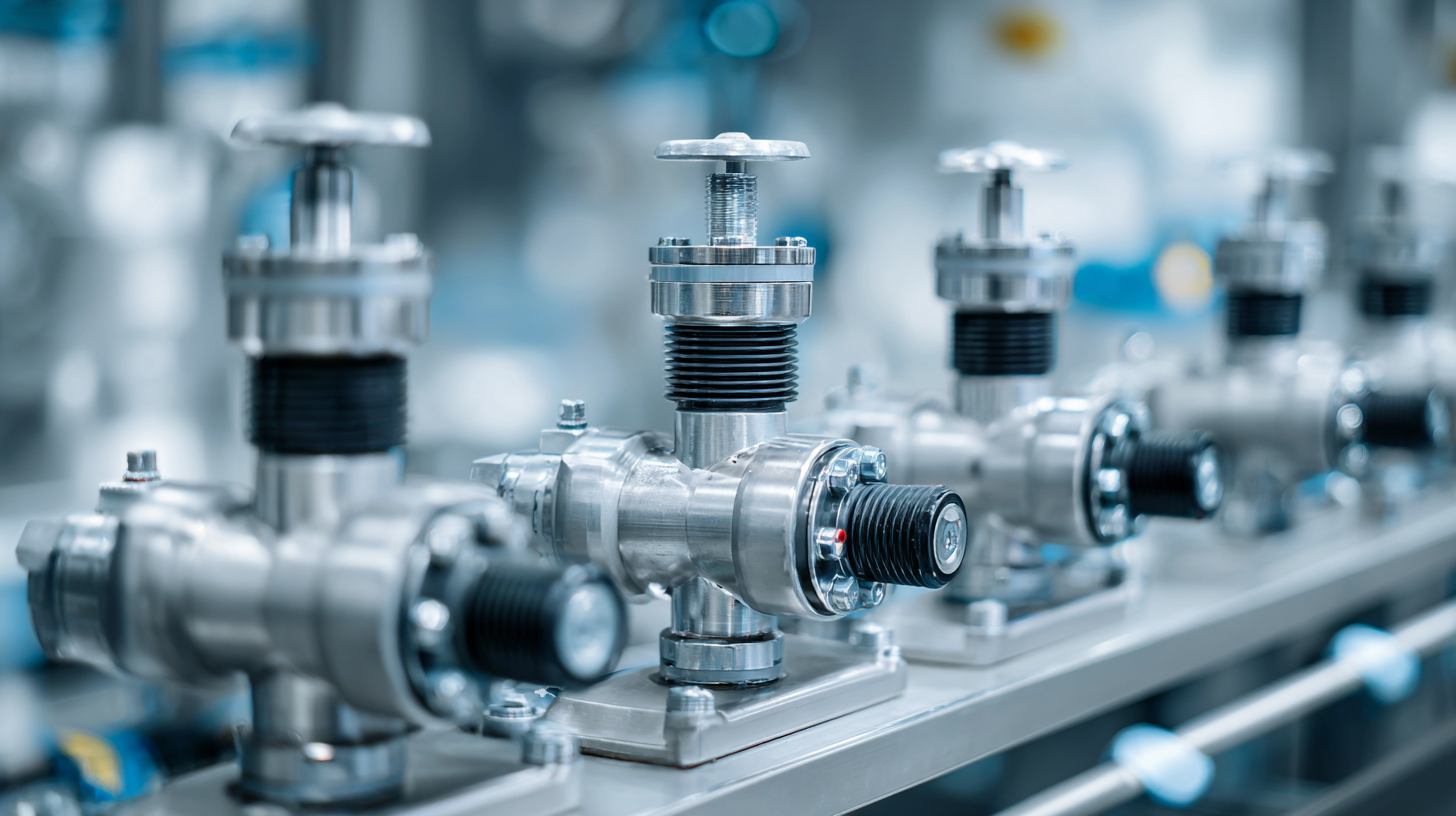

Understanding Different Types of Flow Valves and Their Applications

When selecting flow valves for your business, understanding the different types of valves and their applications is crucial for ensuring efficiency and effectiveness in your operations. Flow valves come in various forms, including gate valves, globe valves, ball valves, and butterfly valves, each serving distinct purposes. For instance, gate valves are ideal for on/off applications with minimal pressure drop, while globe valves excel at regulating flow.

One of the key tips for choosing the right valve is to consider the medium it will control. Whether you're dealing with water, gas, or corrosive substances, selecting a valve designed to handle specific fluids is essential. Additionally, evaluate the environment in which the valve will be used. Extreme temperatures and pressures require robust solutions, such as high-performance ball valves or specially coated valves to resist corrosion.

Another important aspect is understanding the required flow rate for your application. Accurately calculating your flow needs allows you to choose a valve that optimally meets performance criteria, thereby avoiding unnecessary costs and inefficiency. Engaging with a knowledgeable supplier can provide insights into advanced valve technologies that might better suit your business needs.

Key Factors to Consider When Selecting Flow Valves for Your System

When selecting flow valves for your business, it’s crucial to consider several key factors to ensure optimal functionality and reliability. One essential aspect is the operational environment, which includes factors like temperature, pressure, and the type of fluid. For instance, specific valve designs such as light-responsive and corrosion-resistant gas valves have been developed to handle various physical and chemical processes safely and effectively. These characteristics are vital for maintaining precise flow control in applications ranging from natural gas transport to chemical manufacturing.

Additionally, the durability and performance of the valves are greatly influenced by their design. Recent studies on transcatheter heart valves (THVs) have shown that deformation can significantly impact valve functionality and longevity. This finding underscores the importance of choosing valves that not only meet current operational demands but also provide long-term reliability. Furthermore, analysis of isolation valves in water distribution networks reveals that performance assessment and maintenance practices are pivotal for ensuring efficiency and effectiveness in fluid management systems. Investing in high-quality, appropriately-sized valves tailored to your specific requirements can enhance overall system performance and prevent costly downtime.

Flow Valves Selection Criteria Analysis

Evaluating Material Compatibility to Ensure Optimal Performance

When selecting flow valves for your business, evaluating material compatibility is critical for ensuring optimal performance and longevity. According to a report published by the Flow Control Institute, nearly 30% of valve failures in industrial applications are attributed to material degradation due to environmental exposure and chemical reactions. This underscores the importance of selecting materials that can withstand the specific conditions of your operation, be it high temperatures, corrosive substances, or particulate-laden flows.

Material selection should consider not only the chemical composition but also the physical properties of the valve materials. For example, stainless steel valves are often favored for their corrosion resistance, yet they may not perform well in acidic environments. The Society of Manufacturing Engineers notes that using the appropriate elastomer seals can significantly enhance performance and minimize the risk of leaks. In fact, the right sealing materials can extend valve life by up to 50%, significantly reducing maintenance costs. Ultimately, a thorough understanding of material compatibility will not only optimize flow control but also contribute to sustainable operation and reduced downtime.

10 Tips for Choosing the Right Flow Valves for Your Business Needs

| Tip Number | Tip | Material Compatibility | Applications | Temperature Range (°F) |

|---|---|---|---|---|

| 1 | Determine Flow Requirements | PVC, CPVC | Water Treatment | 32 to 140 |

| 2 | Consider Pressure Ratings | Stainless Steel | Oil & Gas | -40 to 300 |

| 3 | Identify Chemical Compatibility | PTFE | Chemical Processing | -100 to 500 |

| 4 | Assess Flow Direction | Brass | Hydronic Heating | 32 to 250 |

| 5 | Select Valve Type (Manual vs. Automatic) | Nylon | Food & Beverage | 32 to 175 |

| 6 | Evaluate Size & Interfacing Options | Cast Iron | Wastewater Management | -20 to 150 |

| 7 | Check Maintenance Requirements | Aluminum | Pharmaceuticals | 32 to 220 |

| 8 | Consider Automation Needs | Hastelloy | Marine Applications | -50 to 800 |

| 9 | Review Cost-Effectiveness | Copper | Heating & Cooling Systems | 32 to 250 |

| 10 | Consult with Experts | Carbon Steel | Industrial Applications | -50 to 300 |

Assessing Flow Rate Requirements for Your Specific Business Needs

When selecting flow valves for your business, understanding your specific flow rate requirements is critical. Every industry has unique demands, whether you are in manufacturing, food processing, or chemical production. Begin by analyzing the volume of fluid your application will handle over time. This will help determine the size and type of valve you need. Accurate calculations prevent issues like pressure drops or flow restrictions that can lead to operational inefficiencies and increased costs.

In addition to assessing the maximum flow rate, consider the variability of flow in your processes. Does your operation require constant flow, or will it experience fluctuations? Knowing this will guide you toward the right valve type, such as globe valves for throttling or ball valves for on-off control. Moreover, pay attention to the fluid characteristics, including viscosity and temperature, as these factors influence valve performance. By carefully evaluating these elements, you can choose flow valves that not only meet your current requirements but also adapt to future changes in your business needs.

Importance of Maintenance and Reliability in Flow Valve Selection

When selecting flow valves for your business,

maintenance and reliability should be at the forefront of your decision-making process.

According to a report by the International Journal of Fluid Control, approximately 30% of operational failures in industrial settings can be traced back to poor valve selection and inadequate maintenance practices.

This highlights the necessity of choosing valves that not only fit your system's functional requirements but also have a proven track record of reliability and ease of maintenance.

Investing in high-quality flow valves can significantly affect the longevity and efficiency of your operations.

The Valve Manufacturers Association notes that properly maintained valves can extend their service life by up to 50%, reducing long-term costs associated with replacements and unplanned downtime.

When evaluating your options, consider valves that offer features like corrosion resistance and easy access for maintenance, as these can minimize the risk of costly failures and enhance the overall reliability of your systems.

Related Posts

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

What are the Benefits of Using Pressure Valves in Industrial Applications

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

skip to Main Content

skip to Main Content