How to Choose the Right Pump Valves for Your Industrial Needs

Selecting the appropriate pump valves for industrial applications is crucial to optimizing efficiency and ensuring reliability in fluid management systems. According to a recent market research report by Global Industry Analysts, the global valves market is projected to reach $86.2 billion by 2026, driven by the increasing demand for enhanced infrastructure and automation across industries. The choice of pump valves directly impacts operational performance, maintenance costs, and energy consumption. With numerous types and configurations available, industry professionals must consider factors such as fluid type, pressure ratings, and environmental conditions. Proper selection not only minimizes downtime but also enhances system longevity and compliance with safety standards. This article aims to provide insights into how to effectively choose the right pump valves tailored to your specific industrial needs.

Understanding Different Types of Pump Valves and Their Applications

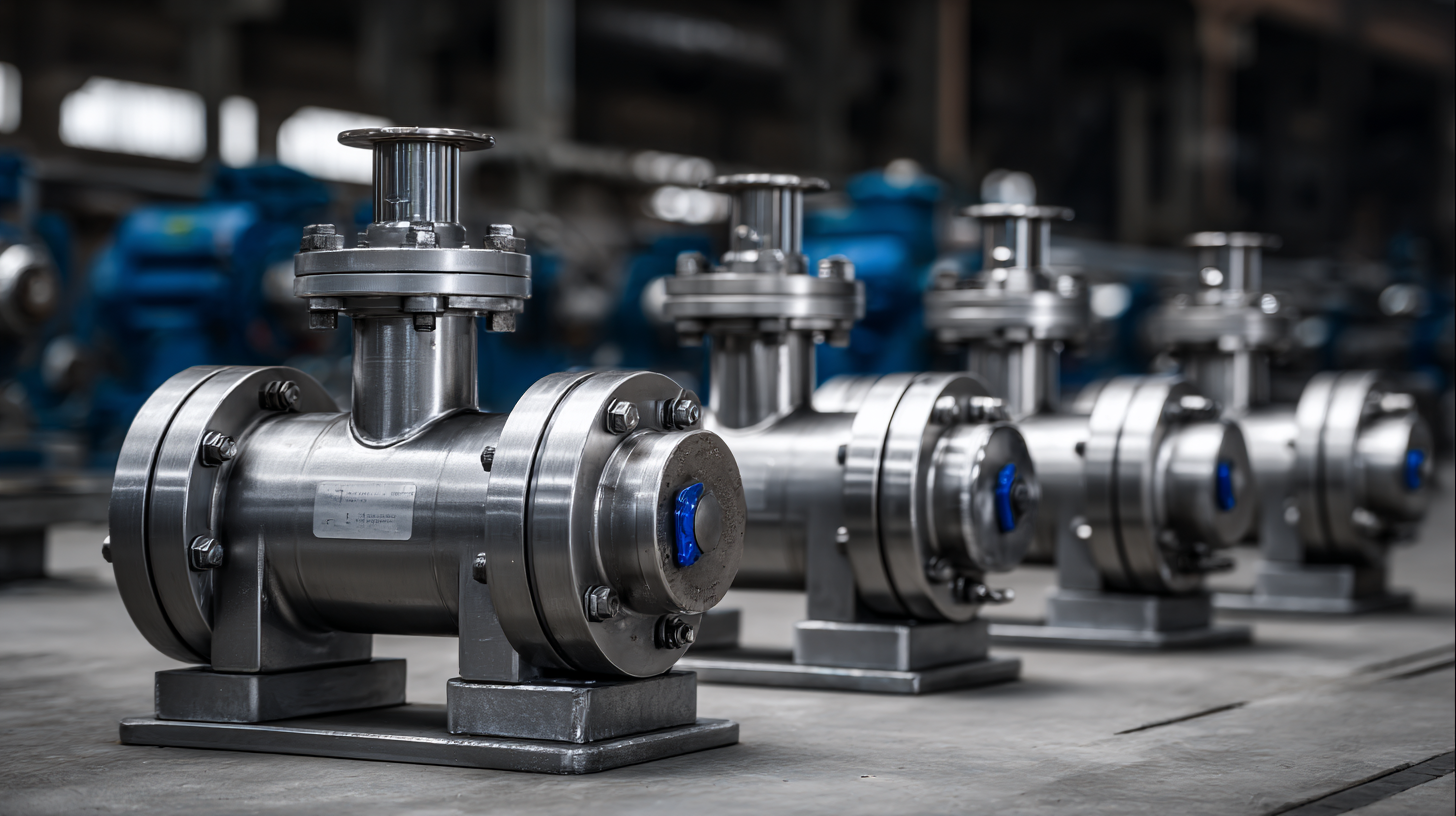

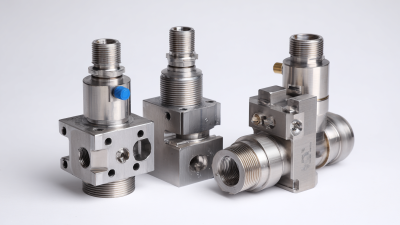

When selecting the appropriate pump valves for industrial applications, it is essential to understand the various types available and their specific functions. Common types of pump valves include check valves, ball valves, gate valves, and globe valves. Check valves are typically used to prevent backflow in a system, ensuring that fluids only move in one direction. Ball valves, known for their quick operation and tight sealing capabilities, are ideal for on/off control in applications involving high flow rates.

Gate valves are well-suited for situations where a minimal pressure drop is crucial, as they allow for free passage of media when fully open. They are often used in systems requiring infrequent maintenance. On the other hand, globe valves are excellent for regulating flow, making them a preferred choice in applications requiring precise control.

When choosing the right valve, it is important to consider factors such as pressure, temperature, and the nature of the fluid being handled, ensuring that the selected valves will perform optimally in their intended environment.

Key Factors to Consider When Selecting Pump Valves for Industry

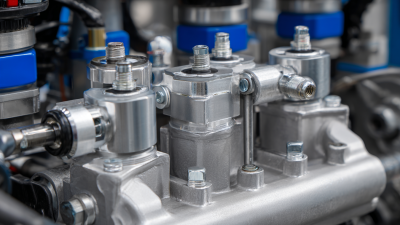

Selecting the right pump valves for industrial applications requires careful consideration of several key factors. The type of fluid being handled, pressure requirements, and operating temperature are crucial elements that need to be assessed. For instance, corrosive substances necessitate materials that can withstand aggressive environments, such as stainless steel or specialized plastics. Additionally, understanding the fluid’s viscosity can dictate the valve design, ensuring optimal flow rates and efficiency.

**Tips:** Always evaluate the compatibility of the valve material with the fluid to prevent degradation. It’s also essential to consider the maintenance requirements of the valves; easy access for servicing can significantly reduce downtime in operations.

Another critical aspect is the valve’s size and connection type. Proper sizing ensures that the pump can handle the required flow rate without unnecessary strain. Furthermore, match the connection type—such as threaded, flanged, or welded—to the existing piping system for a secure fit.

**Tips:** Use flow rate calculations to determine the most appropriate valve size, as this will promote efficiency and prolong the lifespan of the system. Engaging with a knowledgeable supplier can also facilitate a better understanding of specific valve performance metrics relevant to your industrial context.

Assessing Flow Rate and Pressure Requirements for Pump Valve Selection

Choosing the right pump valves for industrial applications is crucial for optimal performance and efficiency. The flow rate and pressure requirements serve as primary determinants in this selection process. Understanding the specific needs of your system will guide you to choose valves that can accommodate the desired fluid dynamics. High flow rates may necessitate larger valve openings, while high-pressure applications may require robust materials to withstand the stresses involved.

Tips: First, clearly define your operational parameters by measuring the flow rate and pressure at peak operation. Use a flow meter and pressure gauge for accurate assessment. Additionally, consider the type of fluid being pumped; corrosive or abrasive materials may require specialized valve materials, impacting both flow and pressure capacity.

Another important aspect is to evaluate the compatibility of the valve with existing infrastructure. Features such as the valve's size, type (manual or automatic), and actuation method should align with the operational setup and maintenance capabilities. This ensures that the chosen valve not only meets flow rate and pressure needs but also integrates seamlessly into your industrial processes, reducing downtime and maintenance issues.

Material Compatibility: Choosing the Right Valve for Your Fluid Composition

When selecting pump valves for industrial applications, material compatibility is crucial to ensure optimal performance and longevity. Different fluids exhibit varying chemical properties that can affect the choice of valve materials. For instance, corrosive fluids like acids and alkalis require valves made from materials such as stainless steel, PVC, or PTFE, which can withstand such environments without degrading. Conversely, for non-corrosive fluids, options like brass or cast iron may be appropriate and cost-effective.

Additionally, considering the temperature and pressure requirements of your specific application is vital. High temperatures can lead to material expansion or degradation if the wrong type of valve is chosen. It's essential to review both the chemical composition of the fluid and the operating conditions to select a valve material that maintains integrity under specified conditions. Regular maintenance and inspections should also be part of the consideration to ensure the chosen valve continues to operate effectively throughout its lifespan.

Maintenance and Durability: Evaluating Long-Term Performance of Pump Valves

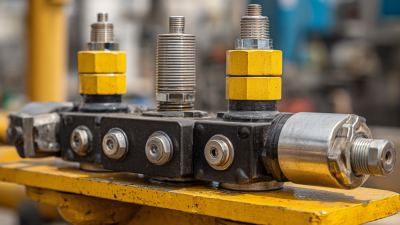

When evaluating the long-term performance of pump valves, it is crucial to consider factors such as maintenance requirements and durability. According to a report by the Hydraulic Institute, approximately 40% of pump failures are due to improperly maintained valves. Regular maintenance not only extends the lifespan of the pump system but also significantly reduces unplanned downtime. Industry best practices recommend a preventative maintenance schedule that includes routine inspections, cleaning, and timely replacement of worn parts to ensure optimal valve operation.

Durability is another key aspect of pump valve performance, particularly in demanding industrial environments. A survey by the American Society of Mechanical Engineers (ASME) indicates that valves made from high-grade materials such as stainless steel can withstand corrosive substances and harsh conditions better than their lower-grade counterparts. Additionally, valves designed with advanced sealing technologies can mitigate leakage risks, enhancing long-term reliability. Investing in durable, well-maintained pump valves is essential for minimizing total lifecycle costs and maximizing operational efficiency in industrial applications.

Related Posts

-

What are the Benefits of Using Pressure Valves in Industrial Applications

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

skip to Main Content

skip to Main Content