How to Choose the Right Electric Valves for Your Industrial Applications

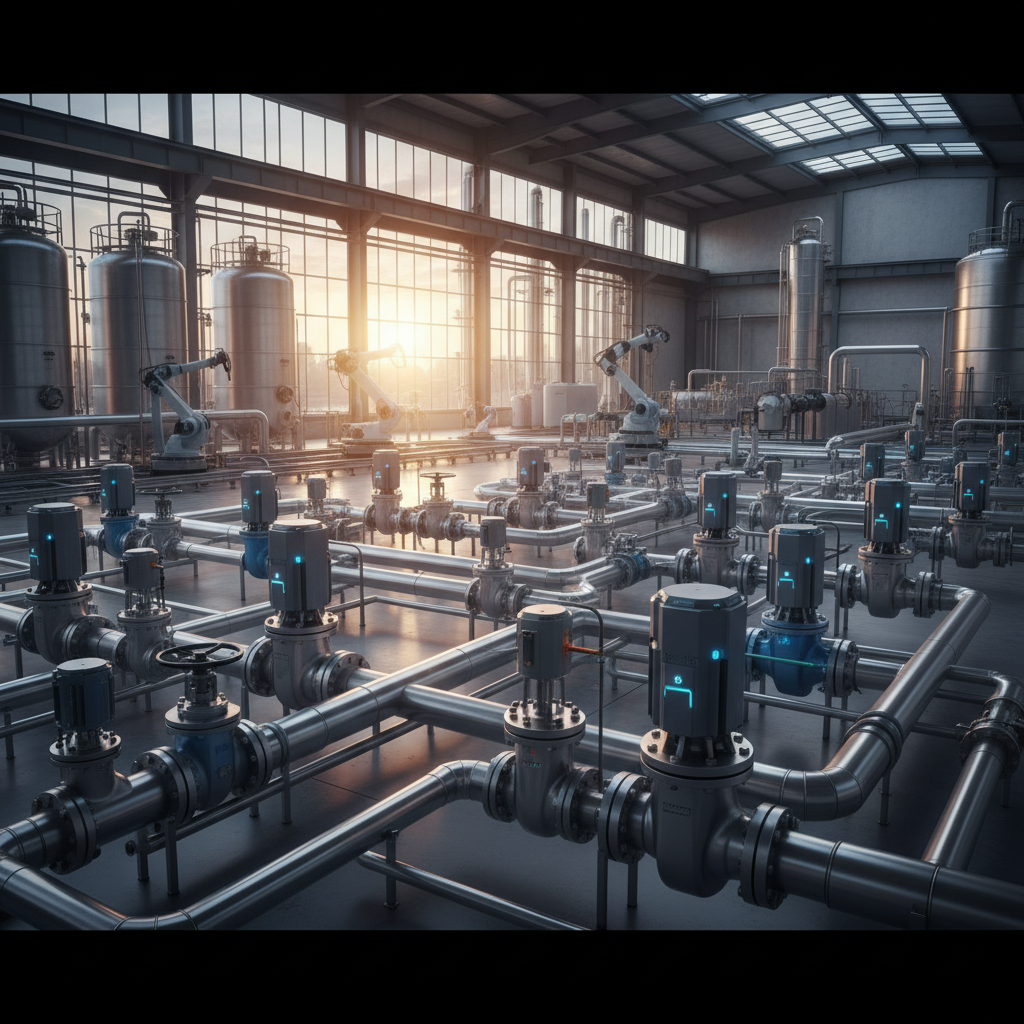

In the rapidly evolving industrial landscape, the selection of the right electric valves is paramount for optimizing process efficiency and enhancing operational reliability. According to a recent report by ResearchAndMarkets, the global electric valves market is expected to reach USD 4.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.3% from 2020. This significant growth underscores the increasing demand for automation and precision in fluid control systems across various sectors, from oil and gas to water treatment and pharmaceuticals.

Industry expert Dr. Emily Hartmann, a recognized authority in valve technology, emphasizes the critical role of electric valves in modern applications: "The choice of electric valves will not only influence the performance but also the safety and compliance of industrial operations." As industries strive for greater efficiency and less downtime, selecting the appropriate electric valves becomes essential in meeting these operational demands. This guide aims to equip industrial professionals with the knowledge required to make informed choices when it comes to electric valves, focusing on the top contenders in 2025.

Understanding Electric Valve Types and Their Functions

Electric valves are critical components in automated industrial processes, facilitating precise control of fluid flow. They can be classified into several types, including globe valves, ball valves, and butterfly valves, each serving specific functionalities. According to a report by MarketsandMarkets, the global electric valve market is expected to reach $11.3 billion by 2025, driven by the increasing demand for automation in various industries.

The choice of valve type greatly influences the efficiency of operations. For instance, ball valves are known for their low pressure drop and ability to handle high flow rates, making them ideal for applications requiring quick shut-off capabilities. Meanwhile, globe valves are well-suited for regulating flow within a pipeline, offering better throttling characteristics.

Additionally, the use of electric actuators provides faster response times and improved energy efficiency, aligning with the industry trend towards greener technologies. By understanding these valve types and their functions, engineers can make informed choices that enhance productivity and reduce operational costs in their applications.

Key Considerations for Selecting Electric Valves in Industry

When selecting electric valves for industrial applications, several key considerations must be taken into account. Firstly, understanding the operating environment is crucial. Factors such as temperature, pressure, and the type of media being handled significantly impact the valve's performance and longevity. According to a report by the International Journal of Industrial Automation, approximately 25% of valve failures are linked to environmental incompatibility, emphasizing the importance of choosing valves that can withstand specific conditions.

Another critical consideration is the size and flow capacity required for your system. Ensuring that the valve is appropriately sized not only optimizes flow but also enhances system efficiency. A recent industry survey indicates that improperly sized valves can lead to a 15% increase in energy consumption, underscoring the need for precise calculations when selecting valves.

Tips: When assessing your needs, it’s beneficial to consult with manufacturers about your specific application. They can provide insights on the best materials and technologies suited for your requirements. Additionally, always check for compliance with industry standards, as this ensures reliability and safety in your operations.

Evaluating Compatibility with Existing Systems and Processes

When selecting electric valves for industrial applications, it is crucial to evaluate their compatibility with existing systems and processes. Begin by assessing the specifications and requirements of your current setup. Consider factors such as voltage ratings, control signals, and operation temperatures, which must align with both the electric valves and the systems they will integrate with. Compatibility issues can lead to inefficiencies or even system failures, making it imperative to refer to technical documentation and consult with manufacturers.

In addition to compatible specifications, it is important to analyze the fluid characteristics, such as viscosity, pressure, and chemical composition. Different electric valves may be suited for specific types of fluids or environments, and understanding these aspects can prevent costly errors. Furthermore, consider the existing control systems in place—whether they utilize analog or digital signals—as this can influence the choice of valve mechanisms and controllers. By thoroughly evaluating these elements, operators can ensure that the selected electric valves will function seamlessly within their industrial applications, ultimately enhancing productivity and safety.

Assessing Performance Metrics and Reliability Standards

When selecting the right electric valves for industrial applications, assessing performance metrics and reliability standards is crucial for ensuring optimal operation. Performance metrics include factors such as flow rate, pressure tolerance, and response time. These metrics help determine how well the valve will perform under specific conditions, ensuring it meets the operational demands of your system. For instance, high flow rates may be necessary in processes that require rapid fluid delivery, while specific pressure ratings can prevent potential failures.

**Tips: When evaluating flow rates, consult manufacturer specifications to ensure compatibility with your existing systems. Additionally, consider the response time; for critical processes, faster response times can lead to better overall efficiency.**

Reliability standards play a vital role in the long-term functionality of electric valves. Standards such as IP ratings for ingress protection and IEC certifications for electrical components should be thoroughly reviewed. This ensures that the valves can withstand environmental factors like moisture, dust, and extreme temperatures. Regular maintenance schedules should also be part of the reliability assessment, as proactive care can extend the lifespan of the valves and prevent costly downtime.

**Tips: Regularly review maintenance protocols and training for personnel on valve operation to maintain reliability. Monitoring system performance can also help detect issues early, facilitating timely intervention.**

How to Choose the Right Electric Valves for Your Industrial Applications - Assessing Performance Metrics and Reliability Standards

| Valve Type | Nominal Size (inches) | Operating Pressure (psi) | Temperature Range (°F) | Material | IP Rating | Expected Lifespan (cycles) |

|---|---|---|---|---|---|---|

| Ball Valve | 2 | 150 | -20 to 200 | Stainless Steel | IP67 | 1,000,000 |

| Gate Valve | 3 | 200 | -5 to 250 | Carbon Steel | IP65 | 500,000 |

| Globe Valve | 1.5 | 100 | -10 to 180 | Brass | IP54 | 300,000 |

| Butterfly Valve | 4 | 75 | -30 to 220 | Plastic | IP68 | 1,500,000 |

| Check Valve | 2.5 | 150 | -10 to 180 | Stainless Steel | IP55 | 400,000 |

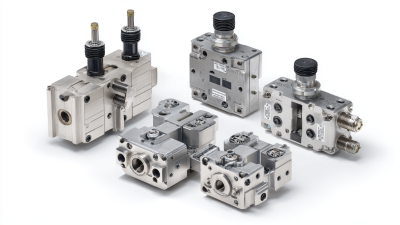

Exploring Leading Brands and Their Top Electric Valve Models for 2025

When selecting electric valves for industrial applications in 2025, it's crucial to consider the reputation and reliability of leading brands in the market. Notable manufacturers such as Siemens, Honeywell, and Parker Hannifin have established themselves by offering advanced technologies and robust designs. For instance, Siemens provides electric actuators that feature precise control and high durability, making them ideal for demanding environments. Similarly, Honeywell’s electric valves are known for their energy efficiency and smart integration capabilities, which enhance operational performance across various sectors.

In addition to brand reputation, specific models often stand out for their innovative features. The Siemens SIPART PS2 is recognized for its user-friendly interface and adaptability to various applications, ensuring ease of maintenance and operation. On the other hand, Parker Hannifin’s VSO series valves are celebrated for their compact design and exceptional reliability, particularly in harsh conditions. Evaluating these top models against your operational needs can significantly impact efficiency and reliability in your industrial processes, ultimately leading to improved productivity and lower downtime.

Related Posts

-

2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

Understanding the Importance of Pressure Control Valves in Modern Industrial Applications

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

-

Innovative Flow Control Valves on Display at the 138th Canton Fair in 2025

skip to Main Content

skip to Main Content