How to Choose the Right Hydraulic Solenoid Valves for Your Applications

In today's dynamic industrial landscape, the choice of appropriate hydraulic solenoid valves is critical for optimizing system performance and ensuring the reliability of various applications. According to a recent report by MarketsandMarkets, the global hydraulic valves market is projected to reach $6.02 billion by 2027, with an increasing demand for hydraulic solenoid valves driven by advancements in automation and control technologies. This growth underscores the importance of selecting the right components to enhance efficiency and productivity in fluid power systems.

Renowned industry expert Dr. Emily Carter, an authority in fluid dynamics, emphasizes that "the appropriate selection of hydraulic solenoid valves directly impacts the operational efficacy of hydraulic systems." Her insights reflect a growing recognition among manufacturers and engineers of the critical role these valves play in applications ranging from mobile machinery to process control systems. As organizations strive to improve their operational standards, understanding the nuances of hydraulic solenoid valves becomes paramount, guiding decision-makers toward solutions that align with their specific application requirements.

Understanding Hydraulic Solenoid Valves and Their Applications

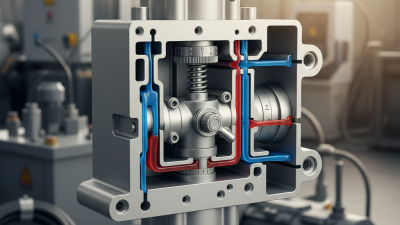

Hydraulic solenoid valves play a crucial role in the control of fluid flow within hydraulic systems, acting as the components that open or close pathways to enable the operation of machinery. These valves are actuated by an electric current that controls the solenoid, allowing for precise fluid management, which is essential in various applications such as automotive systems, industrial machinery, and aerospace technologies. According to a recent report by MarketsandMarkets, the global hydraulic valves market is projected to reach $36.9 billion by 2025, highlighting the increasing demand for efficient fluid control solutions across various sectors.

Understanding the specifications and functionalities of hydraulic solenoid valves is vital for choosing the right products for specific applications. Key factors to consider include the valve type (such as 2-way or 3-way), the operating pressure range, response time, and the type of fluid involved. A study from The Freedonia Group indicates that advancements in valve design, including the incorporation of smart technology and improved materials, have enhanced durability and responsiveness, catering to the evolving needs of industries aiming for higher efficiency and reliability. Recognizing these parameters can significantly streamline operations and improve overall system performance, leading to cost savings and increased productivity in hydraulic applications.

Key Factors to Consider When Selecting Hydraulic Solenoid Valves

When selecting the right hydraulic solenoid valves for your applications, there are several key factors to keep in mind. First and foremost is the valve type, which generally falls into two categories: normally closed (NC) and normally open (NO). According to a MarketsandMarkets report, the growth rate for hydraulic components, including solenoid valves, is projected at 6.5% annually, reflecting the rising demand for efficient fluid control in various industrial applications. Choosing the appropriate valve type not only affects the performance but also the overall system efficiency.

Another critical factor is the voltage rating of the solenoid. Most hydraulic solenoid valves are available in various voltage options, typically ranging from 12V to 240V. This contingent selection ensures compatibility with existing systems and power supplies. A comprehensive study by Technavio highlights that improper voltage selection can lead to increased failures and operational downtime, emphasizing the need for careful consideration in this area. Additionally, understanding the fluid characteristics, such as viscosity and temperature range, will aid in selecting valves that not only perform well but also enhance the longevity of the hydraulic systems.

How to Choose the Right Hydraulic Solenoid Valves for Your Applications - Key Factors to Consider When Selecting Hydraulic Solenoid Valves

| Factor | Description | Importance | Recommended Action |

|---|---|---|---|

| Operating Pressure | Consider the maximum pressure in your system. | High | Select valves rated for pressures exceeding your system's max. |

| Flow Rate | Measure the required flow for your application. | Medium | Choose valves that accommodate your flow requirements. |

| Voltage Options | Verify voltage compatibility with existing systems. | High | Ensure voltage matches your control system. |

| Response Time | Assess how quickly the valve needs to respond. | Medium | Select valves with fast actuation features if needed. |

| Environmental Conditions | Consider temperature, humidity, and exposure to chemicals. | High | Choose materials compatible with your environment. |

Types of Hydraulic Solenoid Valves and Their Specific Uses

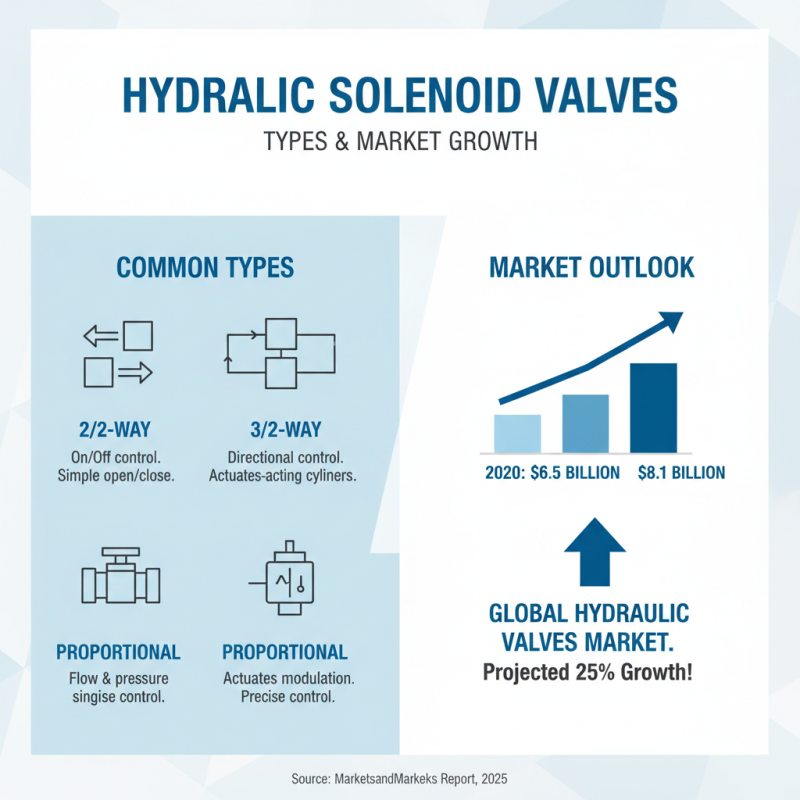

When selecting hydraulic solenoid valves, understanding the various types and their specific applications is crucial. The most common types include 2/2-way, 3/2-way, and proportional valves. According to a recent industry report by MarketsandMarkets, the global hydraulic valves market is projected to reach $8.1 billion by 2025, highlighting the increasing demand for effective valve solutions across multiple sectors, including construction, agriculture, and industrial manufacturing.

2/2-way valves are typically employed for simple on-off control in hydraulic circuits, making them ideal for applications such as hydraulic cylinders and actuators. The 3/2-way valves, on the other hand, offer more versatility, enabling the direction of fluid flow, which is essential for applications requiring switching between two different output lines, like double-acting cylinders. Additionally, proportional solenoid valves provide variable control, allowing for precise adjustments in flow and pressure. These valves are becoming increasingly popular in advanced applications, such as robotics and automation, as they improve system responsiveness and efficiency, according to the International Journal of Fluid Power.

Choosing the right hydraulic solenoid valve type is integral to optimizing performance and reliability in your hydraulic systems. By understanding the specific uses of each valve type, engineers can better tailor their designs to meet operational demands, drive efficiency, and reduce maintenance costs in their applications.

Evaluating Performance Specifications for Hydraulic Solenoid Valves

When selecting hydraulic solenoid valves for specific applications, evaluating performance specifications is critical for ensuring optimal functionality and efficiency. Key performance metrics such as flow rate, pressure rating, and response time should be carefully assessed. For instance, a report by the Hydraulic Valve Manufacturers Association stated that valves with a flow rate exceeding 30 gallons per minute (GPM) are preferred in high-demand industrial applications, where efficiency significantly impacts overall system performance. These specifications must align with the unique requirements of the hydraulic circuit to avoid operational failures.

Another essential aspect to consider is the duty cycle of the solenoid valve, which indicates how long the valve can be energized without overheating. Industry standards suggest that valves used in continuous operation should have at least a 100% duty cycle, as emphasized in a recent study from the National Fluid Power Association. Additionally, the choice of coil voltage can affect the responsiveness of the valve; for instance, selecting a valve compatible with standard 24V DC can enhance integration within existing systems. By meticulously evaluating these performance specifications, one can ensure that the chosen hydraulic solenoid valve meets the demands of the application while maximizing system reliability and efficiency.

Performance Specifications of Hydraulic Solenoid Valves

This chart illustrates the key performance specifications to consider when selecting hydraulic solenoid valves, including flow rate, operating pressure, response time, and coil voltage. Each of these specifications plays a crucial role in ensuring optimal performance for various applications.

Tips for Maintenance and Troubleshooting of Hydraulic Solenoid Valves

When selecting hydraulic solenoid valves, it’s crucial to consider their maintenance and troubleshooting to ensure optimal performance. Regular maintenance can greatly extend the lifespan of your valves and prevent unexpected failures. One key tip is to regularly inspect the valve’s electrical connections and seals. Loose connections can lead to erratic valve performance, while worn seals can cause leaks, which compromise system efficiency.

Another important aspect is to monitor the operational environment of the valves. Ensure that the valves are not exposed to extreme temperatures or contaminated fluids, as these conditions can lead to premature wear. If issues arise, start troubleshooting by checking power supply and signal integrity. Using a multimeter can help verify that the solenoid is receiving the correct voltage. If the valve is stuck or not responding, cleaning the coil or replacing worn components may be required—early detection can save costs and downtime in hydraulic systems.

Related Posts

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

How to Choose the Right Hydraulic Check Valve for Your System

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

skip to Main Content

skip to Main Content