Top 2025 Trends in Directional Control Valves You Need to Know

In the ever-evolving landscape of fluid power technology, the significance of directional control valves has never been more pronounced. As industries strive for enhanced efficiency and innovation, understanding the intricate mechanisms and emerging trends surrounding these pivotal components is essential. According to Dr. Emily Carter, a leading expert in fluid dynamics, “Directional control valves are the backbone of hydraulic systems, enabling precise control over fluid flow and direction.”

As we anticipate the advancements set to define 2025, it is crucial to delve into the trends that will shape the future of directional control valves. With a growing emphasis on automation, sustainability, and miniaturization, the directional control valve sector is poised for transformative changes that promise improved performance and expanded applications. Awareness of these trends will not only equip engineers and manufacturers with the knowledge to stay competitive but also foster a culture of innovation within the industry. By examining the anticipated developments, we aim to highlight the key elements that will drive the future of directional control valves.

Emerging Technologies in Directional Control Valves for 2025

In 2025, the landscape of directional control valves is poised for transformation, driven by emerging technologies that enhance their functionality, efficiency, and integration with smart systems. Industry reports indicate that the market for directional control valves is projected to grow at a CAGR of 5.2% from 2023 to 2028, primarily due to the increasing demand for automation across various sectors, including manufacturing and automotive. This shift is catalyzed by advancements in microelectronics, enabling valves to operate with higher precision and responsiveness than ever before.

One of the most significant trends is the integration of IoT capabilities into directional control valves. This technology allows for real-time monitoring and data analysis, leading to improved maintenance strategies and reduced downtime. A recent study highlights that smart valves equipped with IoT sensors can reduce maintenance costs by up to 20%, offering manufacturers a clear competitive advantage. Additionally, the use of artificial intelligence in predictive analytics is providing unprecedented insights into valve performance, allowing for proactive adjustments that enhance system efficiency and reliability.

Furthermore, the rise of energy-efficient designs is revolutionizing the industry. Reports from leading engineering firms suggest that by 2025, regulations will increasingly favor valves that minimize energy consumption and environmental impact. Manufacturers are responding with innovations such as low-pressure drop designs and materials that enhance durability while reducing energy usage. By embracing these trends, companies can not only adhere to emerging regulatory standards but also position themselves as leaders in sustainable engineering practices.

Key Industry Drivers Influencing Directional Control Valve Trends

The directional control valve industry is poised for significant changes in 2025, influenced by several key drivers. One major factor is the increasing demand for automation across various sectors, particularly in manufacturing and transportation. As industries strive for greater efficiency and precision, there will be a growing need for advanced directional control valves that can seamlessly integrate with automated systems. This trend is likely to spur innovation in valve technology, focusing on enhancing performance, reducing response times, and optimizing energy consumption.

Another significant driver is the push for sustainability and environmental responsibility. As governments and organizations worldwide emphasize greener practices, the demand for energy-efficient and low-emission solutions in hydraulic and pneumatic systems becomes critical. Directional control valves that comply with strict environmental regulations and support energy-saving initiatives will be in higher demand. Additionally, the development of smart technology within valves, such as IoT connectivity, will enable real-time monitoring and maintenance, further supporting sustainability efforts in various applications. These industry drivers will shape the trajectory of directional control valve trends, ensuring they align with the evolving needs of modern industries.

Sustainability Initiatives Impacting Directional Control Valve Designs

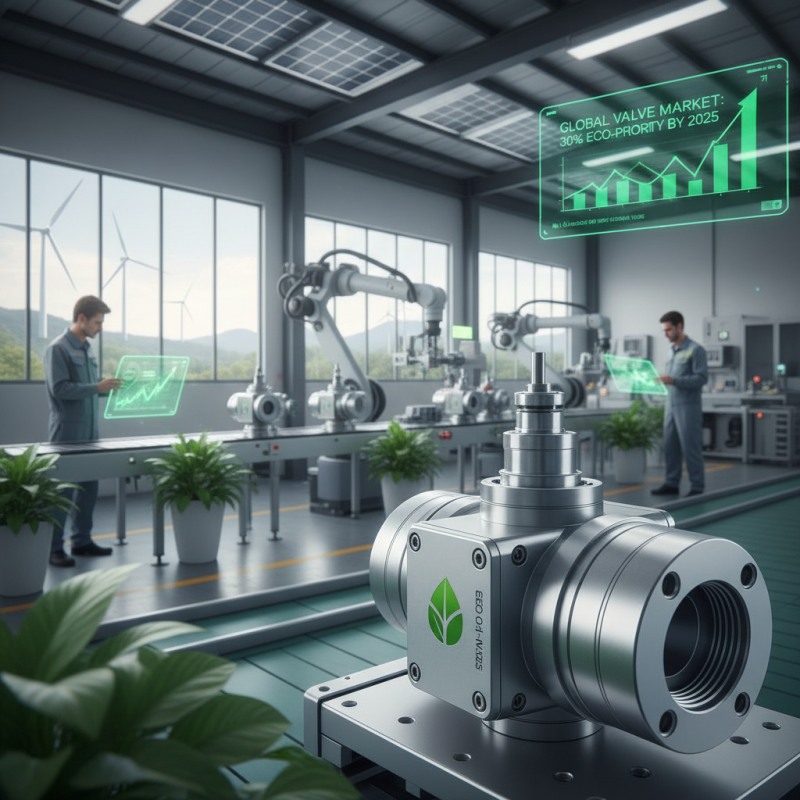

As the demand for environmentally friendly solutions continues to rise, the design and manufacturing of directional control valves are undergoing significant transformations driven by sustainability initiatives. A report from the Global Valve Market indicates that around 30% of valve manufacturers are now prioritizing the development of eco-friendly products by 2025. This shift is largely influenced by regulatory pressures and the increasing recognition of the importance of reducing carbon footprints across industries.

Directional control valves are being re-engineered to use less energy and materials while maintaining efficiency and performance. Advanced materials that are recyclable and have lower environmental impacts are being integrated into new designs. According to a 2022 industry survey, 40% of engineers believe that sustainable material selection is a critical factor in their design processes. Innovations such as smart valves equipped with IoT technology also allow for better monitoring and control, reducing wastage and enhancing operational efficiency.

Tips: When considering new directional control valve designs, it is crucial to evaluate the lifecycle impact of materials used. Opt for designs that not only meet performance specifications but also align with sustainability goals. Additionally, collaborating with suppliers who prioritize environmentally friendly practices can further enhance your commitment to sustainability. For those aiming for competitive advantage, staying ahead of these trends can lead to significant cost savings and improved market positioning.

Integration of Smart Technologies in Directional Control Valves

The integration of smart technologies in directional control valves is revolutionizing the way we manage fluid systems. By incorporating sensors, connectivity, and advanced algorithms, these valves are becoming more intelligent, allowing for enhanced monitoring and control. This shift towards smart technology enables real-time data collection, which can be analyzed to optimize performance, predict maintenance needs, and reduce downtime. As industries increasingly prioritize efficiency and reliability, the adoption of these intelligent systems is expected to grow significant momentum.

Moreover, the implementation of IoT (Internet of Things) in directional control valves facilitates seamless integration with other machinery and systems within a plant. By utilizing cloud-based platforms, operators can access critical information remotely, leading to improved decision-making processes. The ability to adjust valve operations based on real-time feedback not only enhances process efficiency but also contributes to energy savings and reduced operational costs. The synergy between smart technologies and directional control valves is paving the way for a more automated and responsive industrial environment, transforming traditional practices into modern, data-driven operations.

Future Market Predictions for Directional Control Valve Innovations

The future market for directional control valves is poised for significant innovations as industries worldwide strive for enhanced efficiency and automation. As we look toward 2025, the demand for valves that offer greater precision, compact design, and improved energy efficiency will drive technological advancements. The integration of smart technologies, such as IoT connectivity and real-time monitoring, is expected to transform the functionality of directional control valves, allowing for proactive maintenance and reduced downtime.

Additionally, sustainability will play a crucial role in shaping market trends. Manufacturers are likely to focus on developing eco-friendly materials and designs that minimize waste and energy consumption. Innovations in hydraulic systems, including the use of alternative fluids and optimized flow paths, will contribute to a reduced environmental footprint. As industries become more aware of their carbon impact, the emphasis on energy-efficient solutions will reshape the competitive landscape of directional control valve production, setting the stage for a more sustainable future in fluid control systems.

Related Posts

-

2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

What is the Future of Automated Valves in Modern Industries

-

Understanding the Importance of Directional Control Valves in Fluid Power Systems

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

skip to Main Content

skip to Main Content